Flame-retardant polystyrene resin

A polystyrene resin, polystyrene technology, applied in the field of flame retardant polystyrene resin composition, to achieve the effect of improving the resistance to atmospheric aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with specific embodiment:

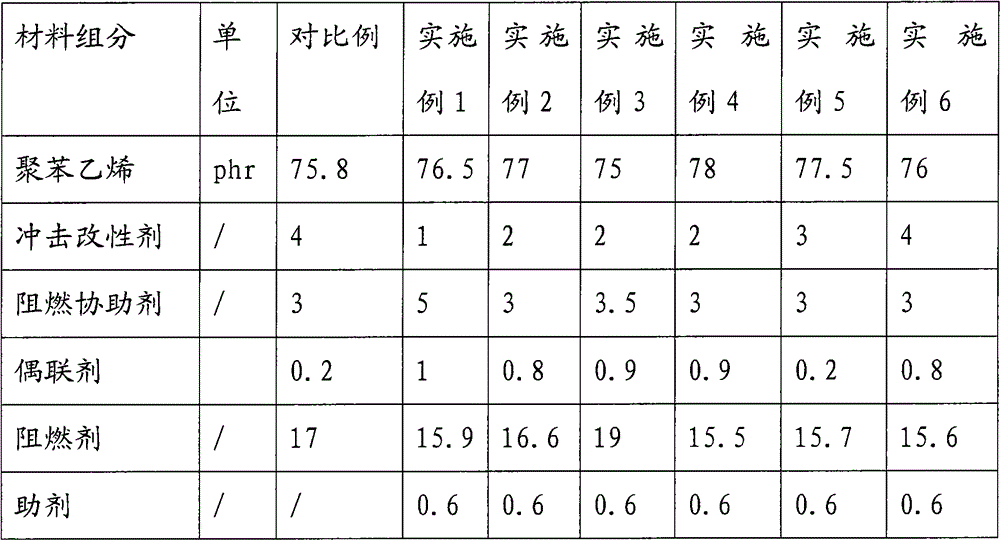

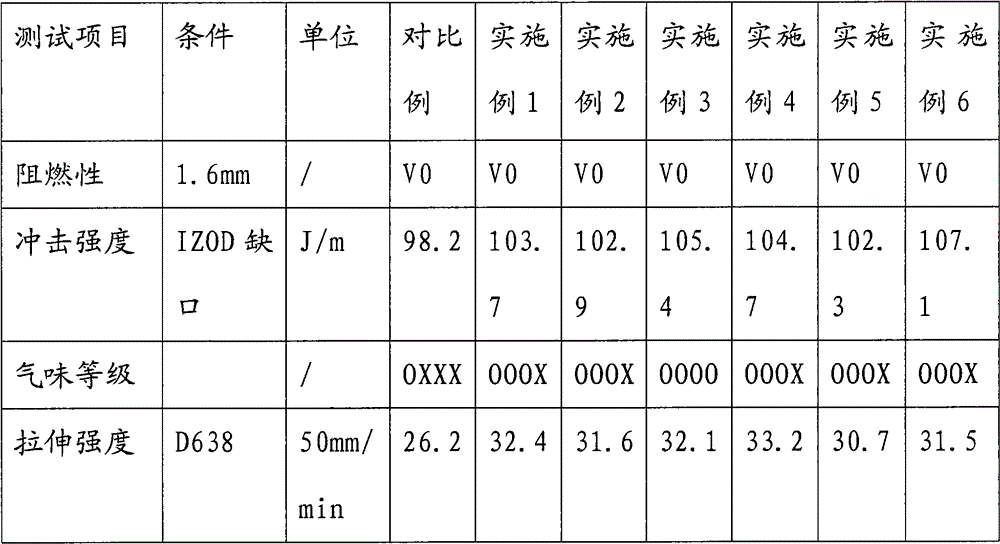

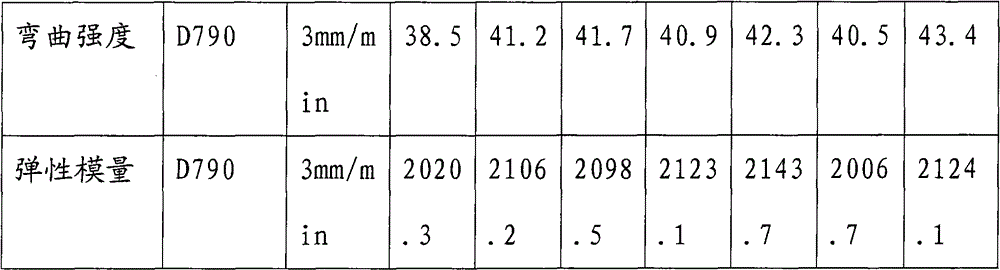

[0026] In the 1-6 embodiments of the present application, the following components are selected, polystyrene selects melt flow rate 10g / 10min, styrene residual monomer content 100ppm, impact modifier in embodiment 1-4 The selected weight percentages are 1, 2, 3, and the selected weight percentages in Examples 5-6 are 4, 5; the flame retardant is titanium dioxide multi-layer coated gray red phosphorus, and the auxiliary agent is selected from the weight percentages 0.6 simethicone, and the coupling agent is selected from silane coupling agents with weight percentages of 0.7, 0.75, 0.8, 0.85, 0.9, and 1.0, respectively.

[0027] Each component used in Examples 1-6 is set as shown in the table below, and each component is premixed according to the amount in the table, and is blended and granulated by a twin-screw extruder with an aspect ratio of 25-40. The extrusion temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com