High-tenacity textured paper tape

A textured paper, high toughness technology, applied in the direction of adhesives, non-polymer organic compound adhesives, film/sheet adhesives, etc., can solve the problems of insufficient adhesion, toughness and temperature resistance, and achieve improved The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, a high-toughness masking tape according to the present invention, which includes masking paper as a base material, one side of the masking paper is provided with an adhesive layer, and the other side of the masking paper is compounded with a polyester film, The other side of polyester film is provided with release paper; Described polyester film is made of the raw material of following percentage by weight, polyethylene terephthalate 35%, barium sulfate 12%, iron dioxide 8%, two Ethylene glycol 15%, methyl methacrylate 10%, styrene-butadiene latex 5%, styrene 5%.

[0050] Further, the composition and parts by weight of the adhesive used in the adhesive layer are as follows: E-44 epoxy resin 100, ethylenediamine 18, dibutyl phthalate 18, methyl methacrylate 50, water 170 , sodium bicarbonate 3,710 alcohol ether phosphate 7, ammonium persulfate 4.

Embodiment 2

[0051] Embodiment 2, a high-toughness masking tape according to the present invention, which includes masking paper as a base material, one side of the masking paper is provided with an adhesive layer, and the other side of the masking paper is compounded with a polyester film, The other side of polyester film is provided with release paper; Described polyester film is made of the raw material of following percentage by weight: polyethylene terephthalate 25%, barium sulfate 12%, iron dioxide 23%, two Ethylene glycol 20%, methyl methacrylate 10%, styrene-butadiene latex 6%, styrene 4%.

[0052] Further, the composition and parts by weight of the adhesive used in the adhesive layer are as follows: E-44 epoxy resin 80, ethylenediamine 10-20, dibutyl phthalate 16-18, methyl methacrylate 40, water 160, sodium bicarbonate 1, 710 alcohol ether phosphate 6, ammonium persulfate 3.

Embodiment 3

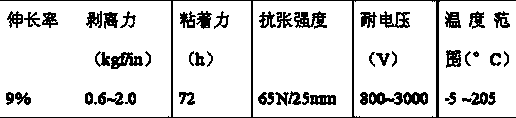

[0053] Embodiment 3, a high-toughness masking tape according to the present invention, which includes masking paper as a base material, one side of the masking paper is provided with an adhesive layer, and the other side of the masking paper is compounded with a polyester film, The other side of polyester film is provided with release paper; Described polyester film is made of the raw material of following percentage by weight: polyethylene terephthalate 30%, barium sulfate 10%, iron dioxide 20%, two Ethylene glycol 18%, methyl methacrylate 12%, styrene-butadiene latex 5%, styrene 5%. Further, the composition and parts by weight of the adhesive used in the adhesive layer are as follows: E-44 epoxy resin 90, ethylenediamine 16, dibutyl phthalate 17, methyl methacrylate 50, water 160 , sodium bicarbonate 2, 710 alcohol ether phosphate 7, ammonium persulfate 2; the above-mentioned high-toughness masking tape can effectively improve initial tack, adhesion, toughness and temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com