Scutching device of wide cloth machine

An open-width device and wide-width technology, applied in the directions of textiles, textiles, auxiliary equipment for papermaking and weaving, etc., can solve the problems of reducing production efficiency, installation difficulties, and time-consuming, etc., to improve work efficiency, convenient use, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

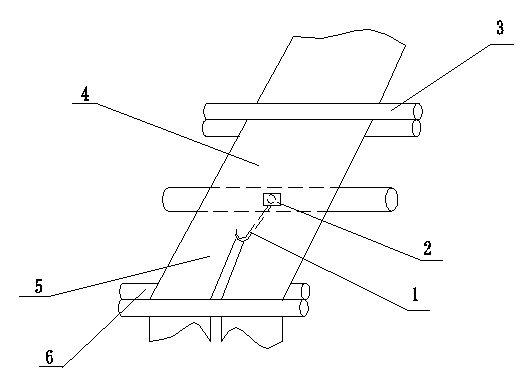

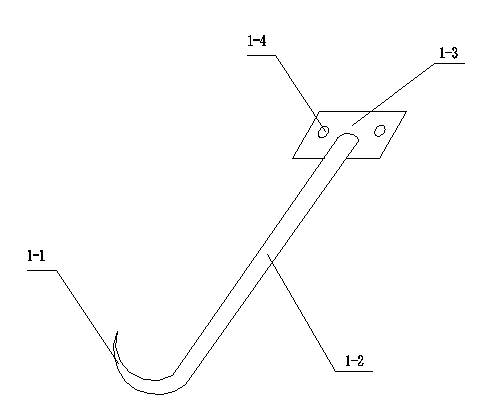

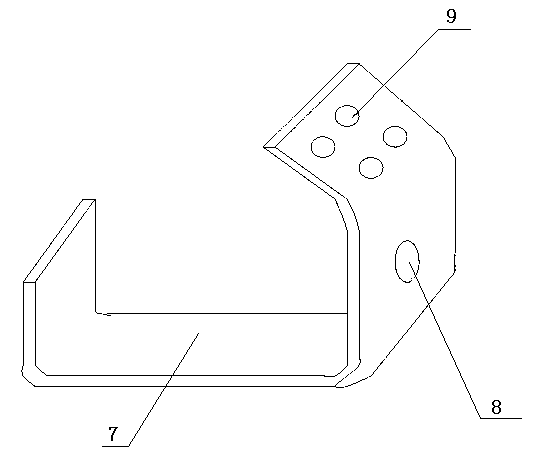

[0018] See attached Figure 1-Figure 4 , an embodiment of the opening device of a wide-width cloth loom of the present invention, including the support 2 in the breast beam, the opening piece, and the warp stop frame. The opening part is a hook knife 1, one end of the knife handle of the hook knife 1 is installed on the support 2 in the chest beam, and the hook knife edge 1-1 is upward. After the machine, a skein yarn bracket 7 and a central skein yarn tension device are arranged, and the central skein yarn tension device comprises a side yarn spring sheet bracket 10, a side yarn spring sheet 12, and the central skein yarn tension device is fixed on The middle front side of the warp stopper, and the hemming yarn bracket 7 is installed on the middle rear side of the warp stopper.

[0019] see figure 2 , the front part of the hook knife 1 is L-shaped, the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com