High-strength reinforcing steel bar self-compaction steel fiber ultrahigh-strength concrete transfer girder

A technology of ultra-high-strength concrete and high-strength steel bars, applied in joists, girders, truss beams, etc., can solve the problems of poor deformation of high-strength steel bars and concrete, inconvenient construction, and crowding of steel bars, reducing cross-sectional size, reducing workload, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

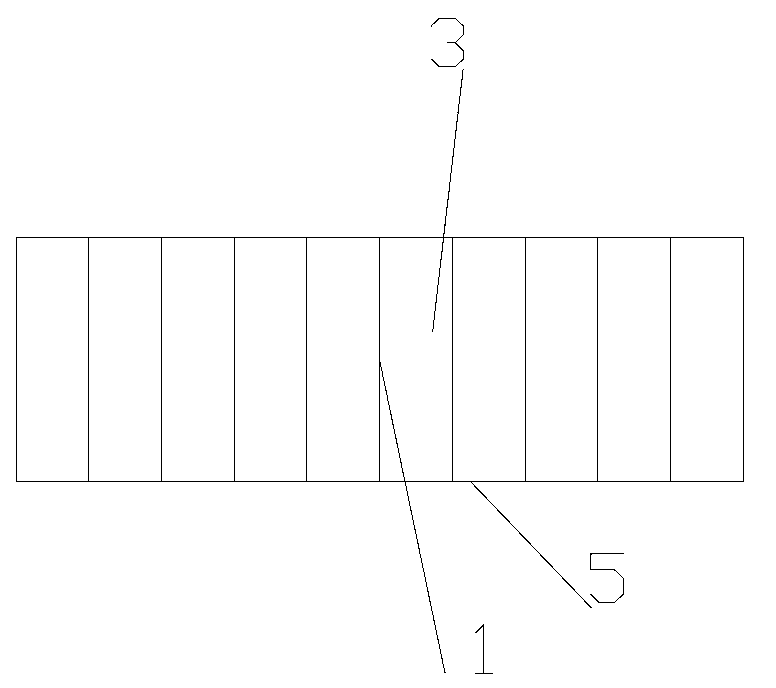

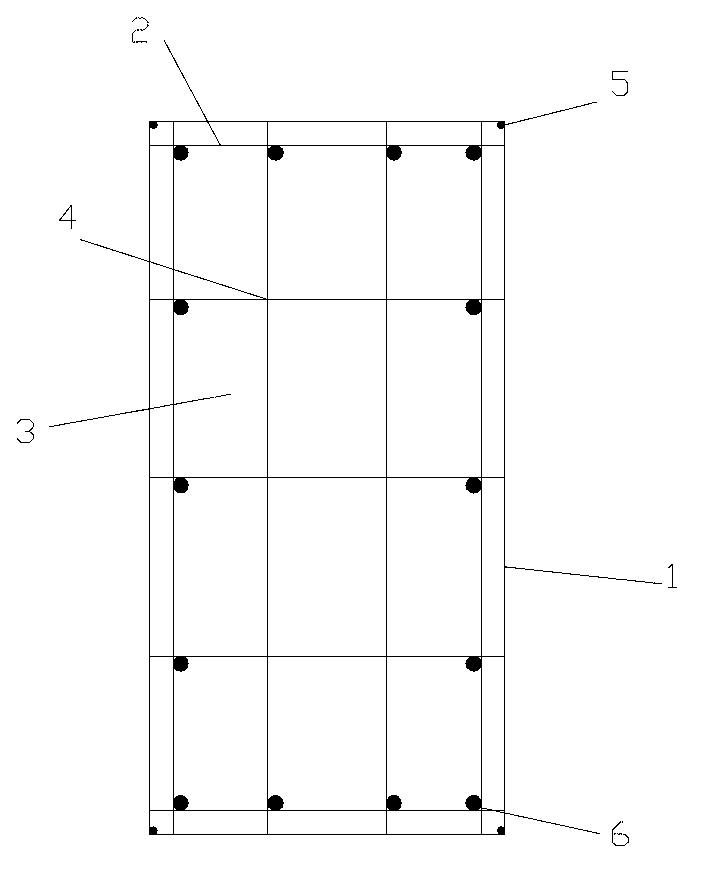

[0041]All longitudinal steel bars and stirrups are processed by a professional steel bar processing company through CNC steel bar processing machines. The size error of the longitudinal steel bars is within ±5mm, and the size error of the stirrups is controlled within ±1mm.

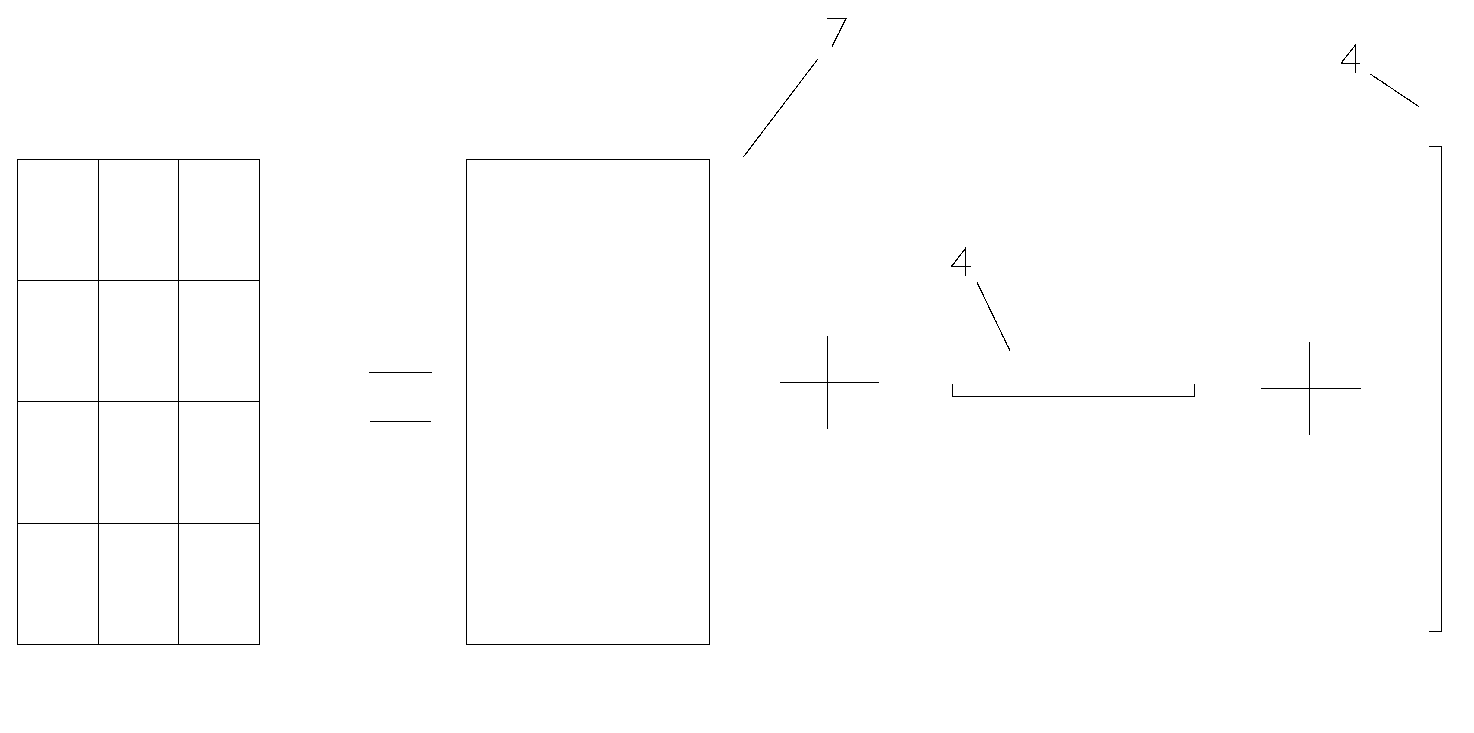

[0042] The closed stirrup 7 can be obtained by lap welding, double-sided welding, the lap length is not less than 5d, and single-sided welding, the lap length is not less than 10d, where d is the diameter of the steel bar.

[0043] Tension bar 4 should leave the crotch of 90 degrees on both sides during processing, and the length of the horizontal section of crotch hook is not less than 5d when double-sided welding, and the length is not less than 10d when single-sided welding, and d is the steel bar diameter.

[0044] Closed stirrups 1 and 2 are obtained by welding closed stirrups 7 and tie bars 4 .

[0045] Bind the stirrups and longitudinal steel bars according to the design drawings, support the formw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com