Anaerobic simple core flooding simulation system simulating method

A core and oil-displacing technology, applied in the field of anaerobic simple core-flooding simulation system, can solve the problems of high construction cost, disordered type, complex composition, etc., and achieve the effects of convenient sampling and easy control of test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation steps are as follows:

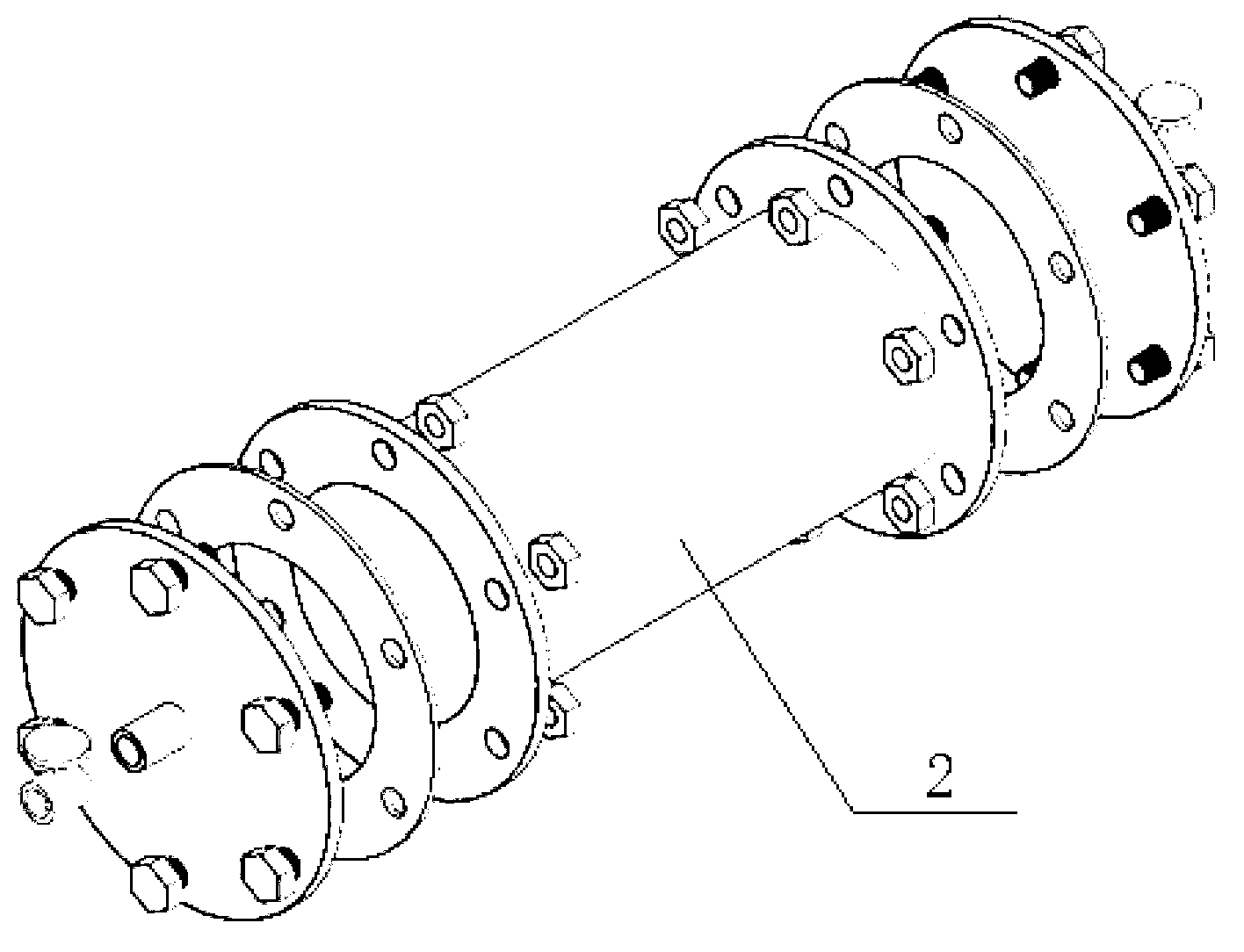

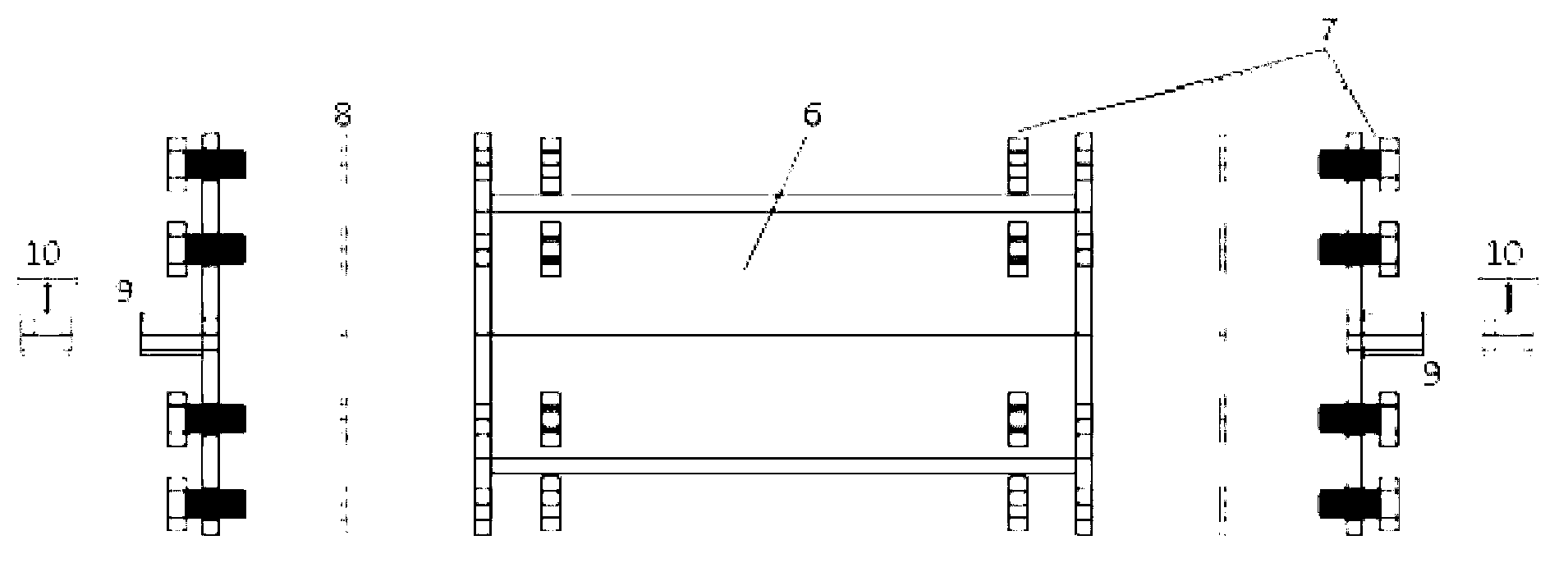

[0032] 1) Take out the core simulation column 2 separately, sterilize it, fill it with other sterile fillers such as core or quartz sand, fill it with saturated saline to remove air, then inject the crude oil to be driven into one end, and discharge the saline solution from the other end to the entire column Filled with crude oil, that is, close the valves at both ends of the column to seal the entire column.

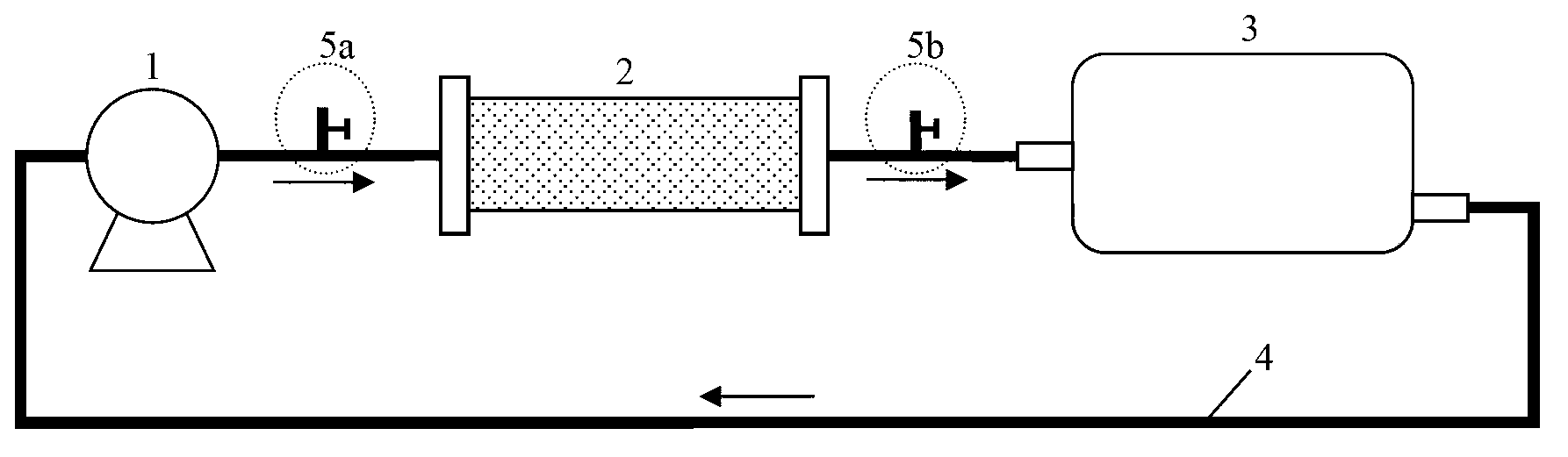

[0033] 2) According to the direction of water flow, according to figure 1 As shown, connect the treated closed core simulation column 2 with the sterilized three-phase separation sampler 3, silica gel pipeline 4, and anaerobic vacuum valve system 5a, 5b, and place a section of silica gel pipeline under the turntable of the peristaltic pump Open the liquid inlet pipe mouth 11 and the liquid outlet pipe mouth 12 valves of the three-phase separation sampler, close the emptying valve 13 and the non-return ventilation pipe m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com