Radiator for power electronic equipment

A technology for power electronics and radiators, which is used in electrical equipment structural parts, electrical components, cooling/ventilation/heating transformation, etc., can solve problems such as difficulty in heat dissipation, and achieve large effective contact area, smooth flow, and real-time gas-liquid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

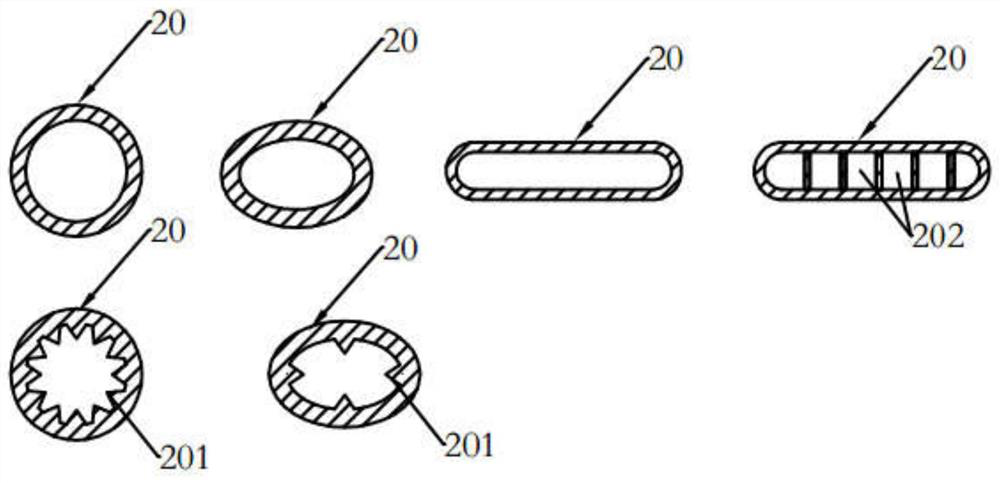

[0036] see Figure 5In this embodiment, there is an uneven pattern on the first capillary structure 13 (as shown in the figure, the shape of the pattern is not limited). There may also be a hollow part (not shown in the figure) on the first capillary structure 13 . The structure of other parts of this embodiment is the same as the above-mentioned first embodiment of the heat sink for power electronic equipment of the present invention, and will not be repeated here.

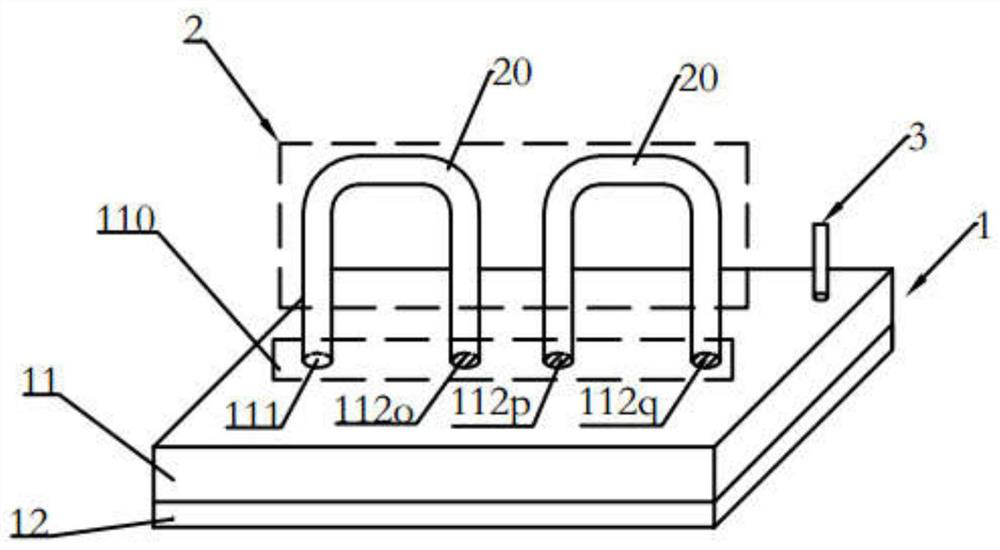

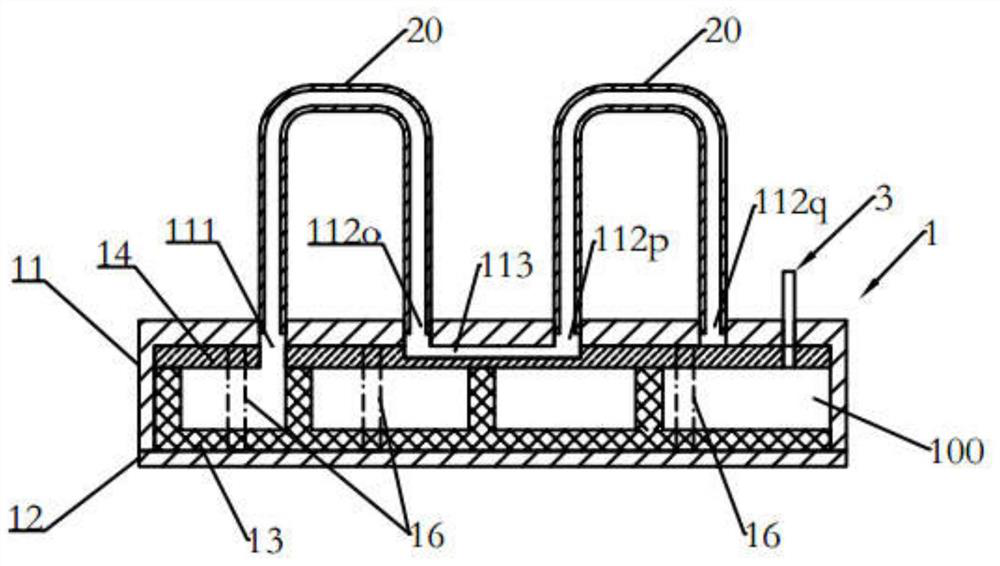

[0037] The radiator of the present invention is particularly suitable for situations where the heat source is installed vertically or obliquely, such as Figure 4 shown. The heat source A is installed vertically, and the bottom plate 12 is in thermal contact with the heat source A. The working fluid absorbs the heat from the heat source and vaporizes, and enters the tube body 20 through the first opening 111 . With the help of gravity, the working medium flows more smoothly, especially the condensed liquid wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com