Wetting-drying cycle tester for water rock

A dry-wet cycle and tester technology, which is applied in the field of test instruments, can solve the problems of cumbersome process, long time-consuming, poor test accuracy, etc., and achieve the effect of avoiding tediousness, shortening test time and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

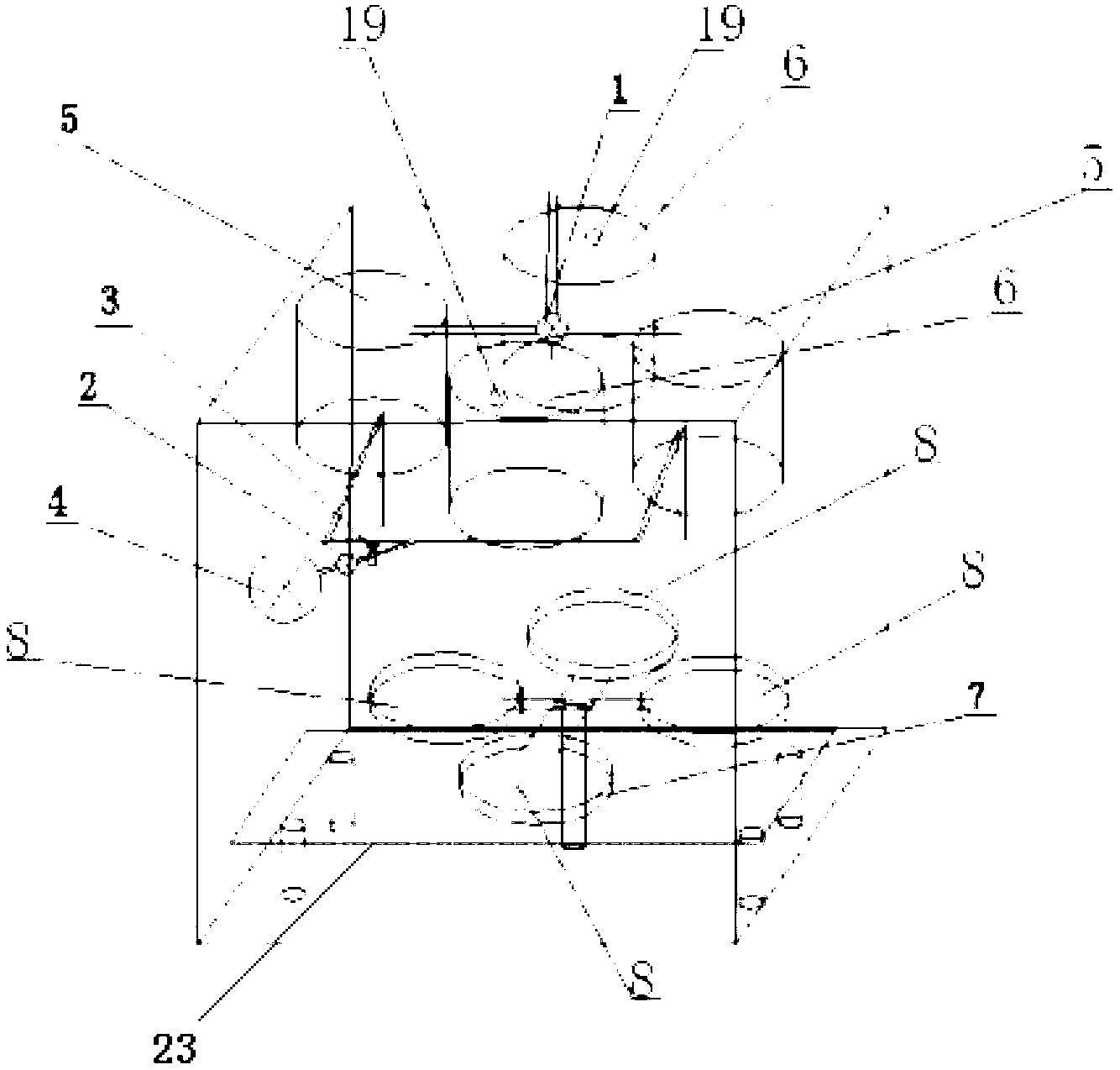

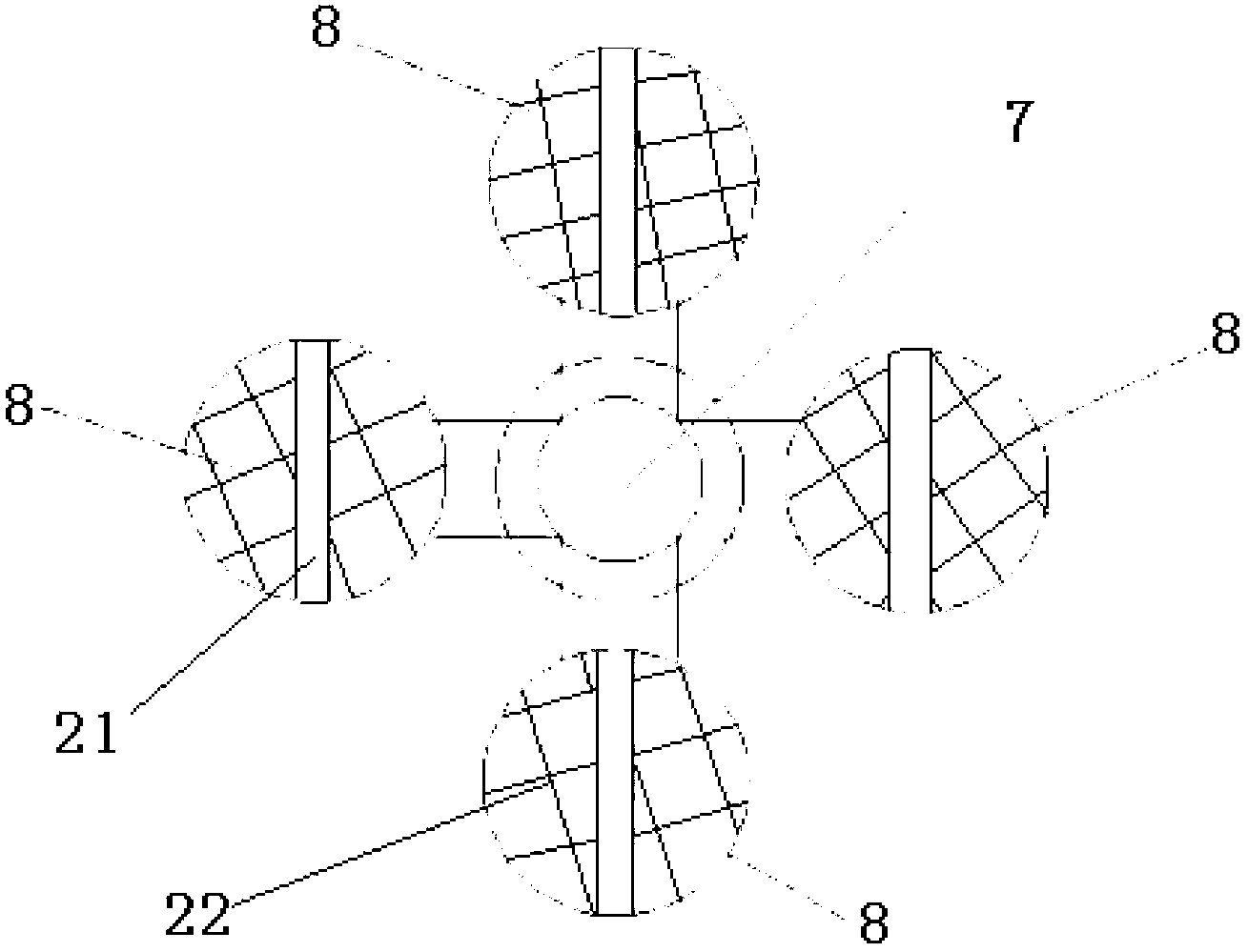

[0022] Comply with the above technical solutions, such as Figure 1 to Figure 6 Shown, a kind of water-rock dry-wet cycle tester comprises test box 9 and support 23, and support 23 is installed in test box 9 bottoms, is fixed with two relative vacuum test boxes 5 and Two relative drying test chambers 6, the vacuum test chamber 5 and the drying test chamber 6 have the same size, and the vacuum test chamber 5 and the drying test chamber 6 are installed at right angles; the two vacuum test chambers 5 are connected with a vacuum pump 1 and two-way water pump 2, the two-way water pump 2 is connected to the liquid storage tank 4 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com