Insulation bandaging process of electric motor winding lead wire connector

A technology of insulating wrapping and motor windings, applied in laying solid insulation and other directions, can solve problems such as weak insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

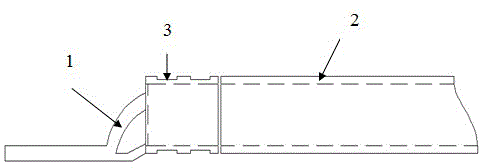

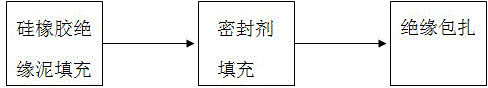

[0017] Such as figure 1 and figure 2 As shown, the insulation wrapping process of the motor winding lead wire joint includes filling with silicone rubber insulating mud, filling with sealant, and insulating wrapping.

[0018] First, silicone rubber insulating mud filling: After the cable joint 1 is welded, clean the welding part, the cable joint and the cable crimping section 3, etc., and cut an appropriate amount of silicone rubber insulating mud to fill in the following two welding laps Groove steps generated: cable joint 1 and cable 2 bare conductor groove and cable joint 1 and lead wire joint overlap groove, it is required that the silicone rubber insulating mud filled in the above two places should not exceed the joint plane, and the transition should be smooth to avoid lapping The location is too thick after subsequent insulation dressing.

[0019] Second, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com