Machine tool table rotation device

A technology for workbenches and machine tools, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the size of worms and worm gears, increasing production costs, and increasing wear of worm gears, so as to reduce wear, improve precision, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

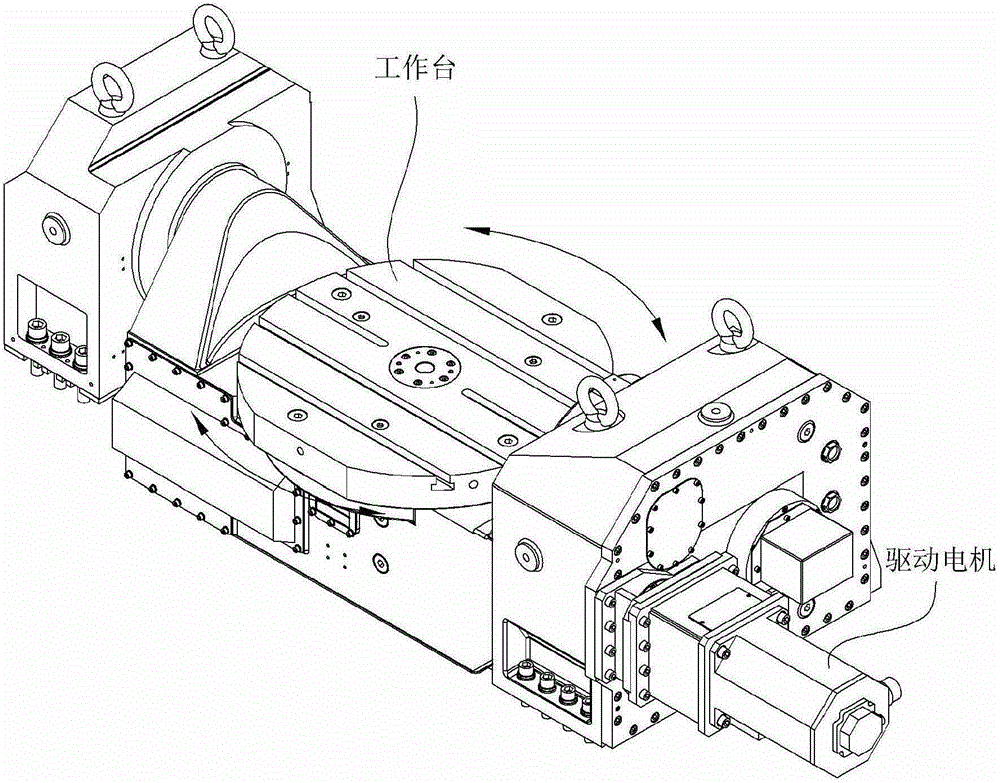

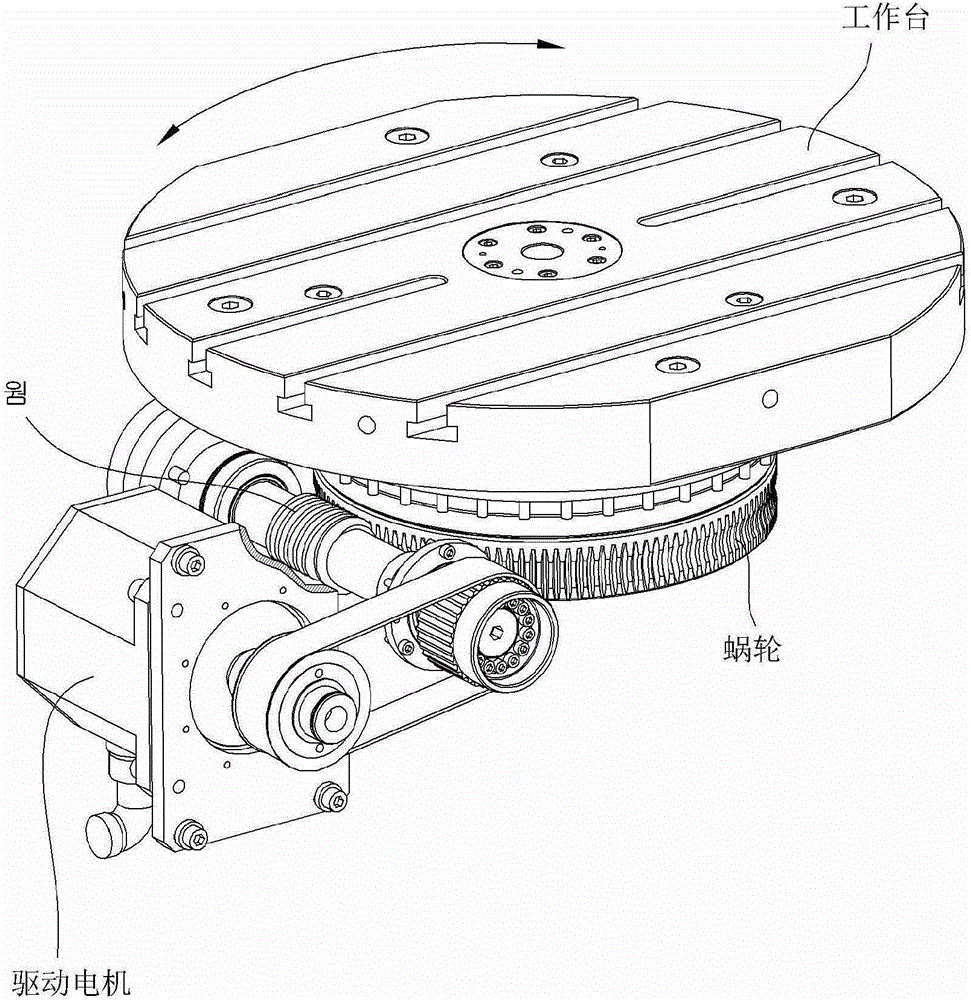

[0032] Reference and attachment Figure 1 The advantages, features and methods for realizing the present invention can be clarified with the detailed embodiments. Hereinafter, a table rotation device for a machine tool according to an embodiment of the present invention will be described with reference to the drawings.

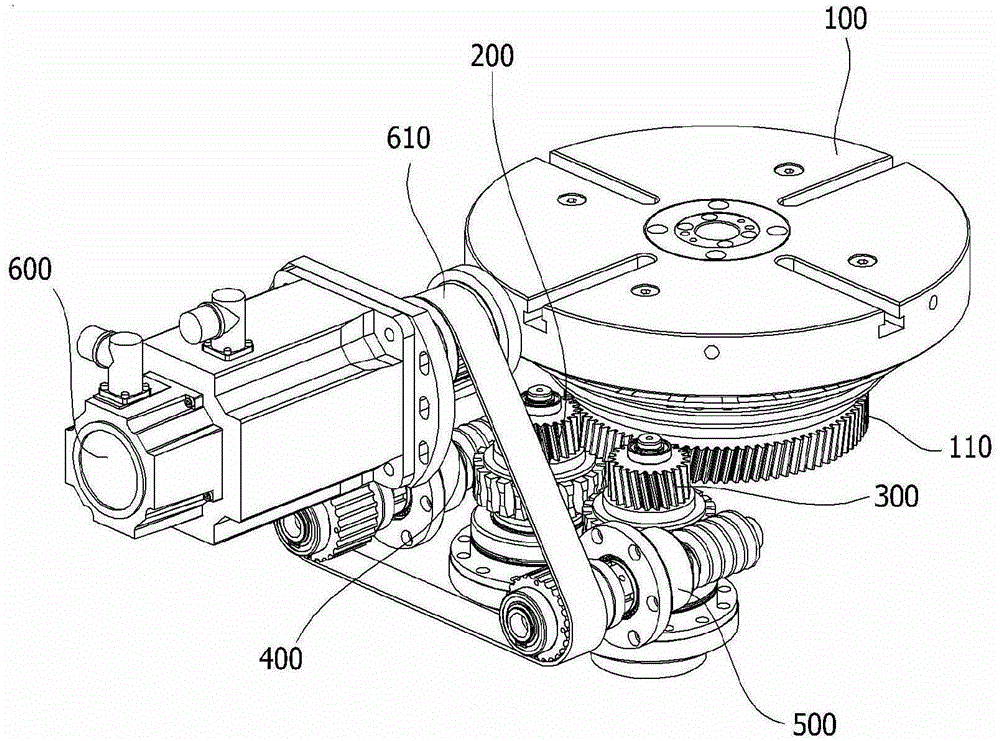

[0033] refer to image 3 and Figure 4 , the table rotating device of a machine tool according to an embodiment of the present invention includes: a table (100), which is used to fix a workpiece; a circular table rotating gear (110), which is arranged under the table (100) side; the first connection gear unit (200), which contacts with one side of the above-mentioned table rotation gear (110) to rotate the above-mentioned table (100); the second connection gear unit (300), which rotates with the above-mentioned table The other side of the gear (110) contacts to rotate the table (100); the first driving gear (400) contacts the first connecting gear unit (200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com