Holder for multiple electrodes in an exhaust line and device with the same

A technology of exhaust pipes and electrodes, which is applied in the direction of exhaust devices, exhaust treatment, noise reduction devices, etc., can solve problems such as different exhaust flows, exhaust components, technical difficulties, etc., and reduce the risk of electrical short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

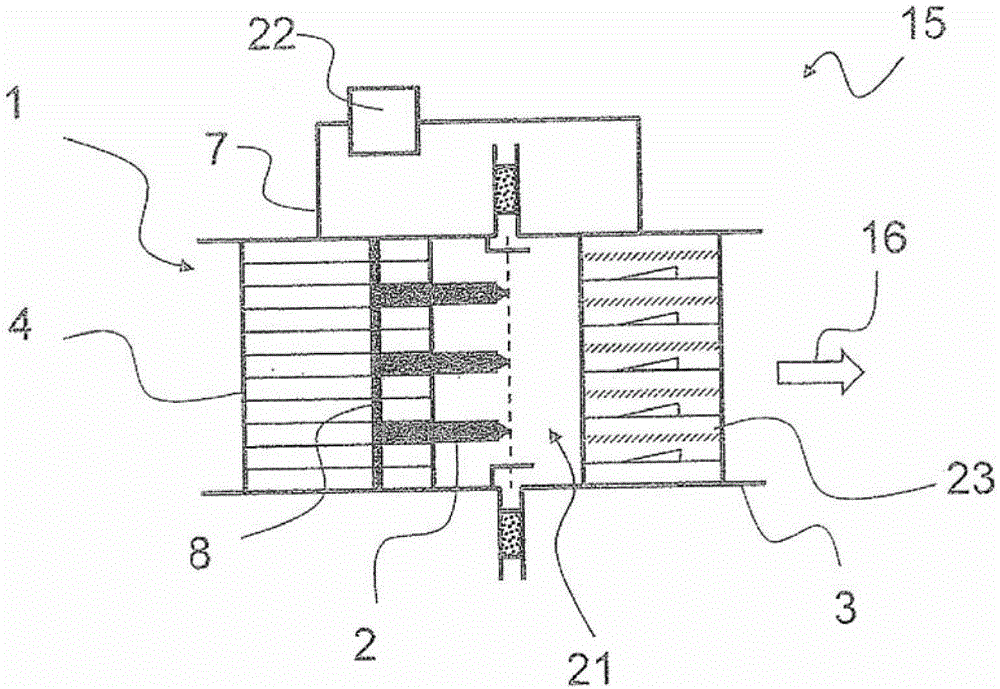

[0033] figure 1 A device 15 for fastening a plurality of electrodes 2 in the exhaust gas line 3 is shown in longitudinal section. In the flow direction 16 of the exhaust gas, firstly a support is provided which has a body 4 through which the exhaust gas can flow. The flow-through body 4 has a plurality of channels running parallel to one another. A plurality of electrodes 2 are arranged distributed in cross-section on the rear side of flow-through body 4 . The device 15 also has an electrical energy supply 22 which supplies an electrical current to the electrodes 2 via the electrical contacts 7 and the distributor 8 . Starting from this electrode 2 , an electric field 21 is formed downstream of the flowable body 4 in the flow direction 16 of the exhaust gas. An electrical potential is formed between the flow-through body 4 and a downstream particle separator 23 which is likewise positioned in the exhaust gas line 3 . In particular, the particle separator 23 is designed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com