Lotus seed coring machine capable of automatically adapting to sizes of lotus seeds

A self-adaptive, lotus seed technology, applied in applications, fruit core removal devices, food science and other directions, can solve the deviation between the center of the core drill bit and the geometric center of the lotus seeds, can not be well adapted to the core removal process, and the core drilling effect cannot achieve the best results. It can ensure the accuracy, reduce the floor space, and coordinate the movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

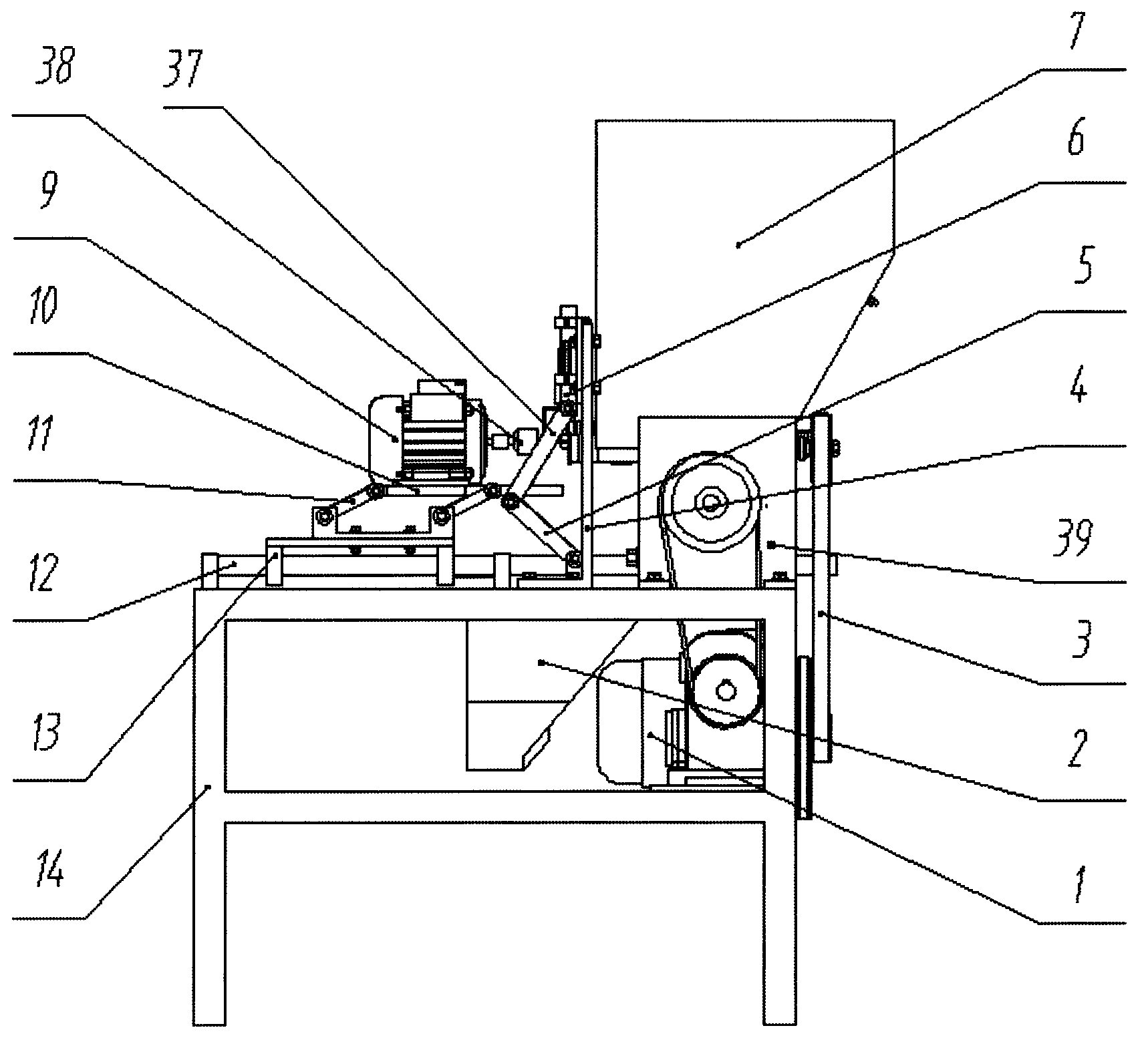

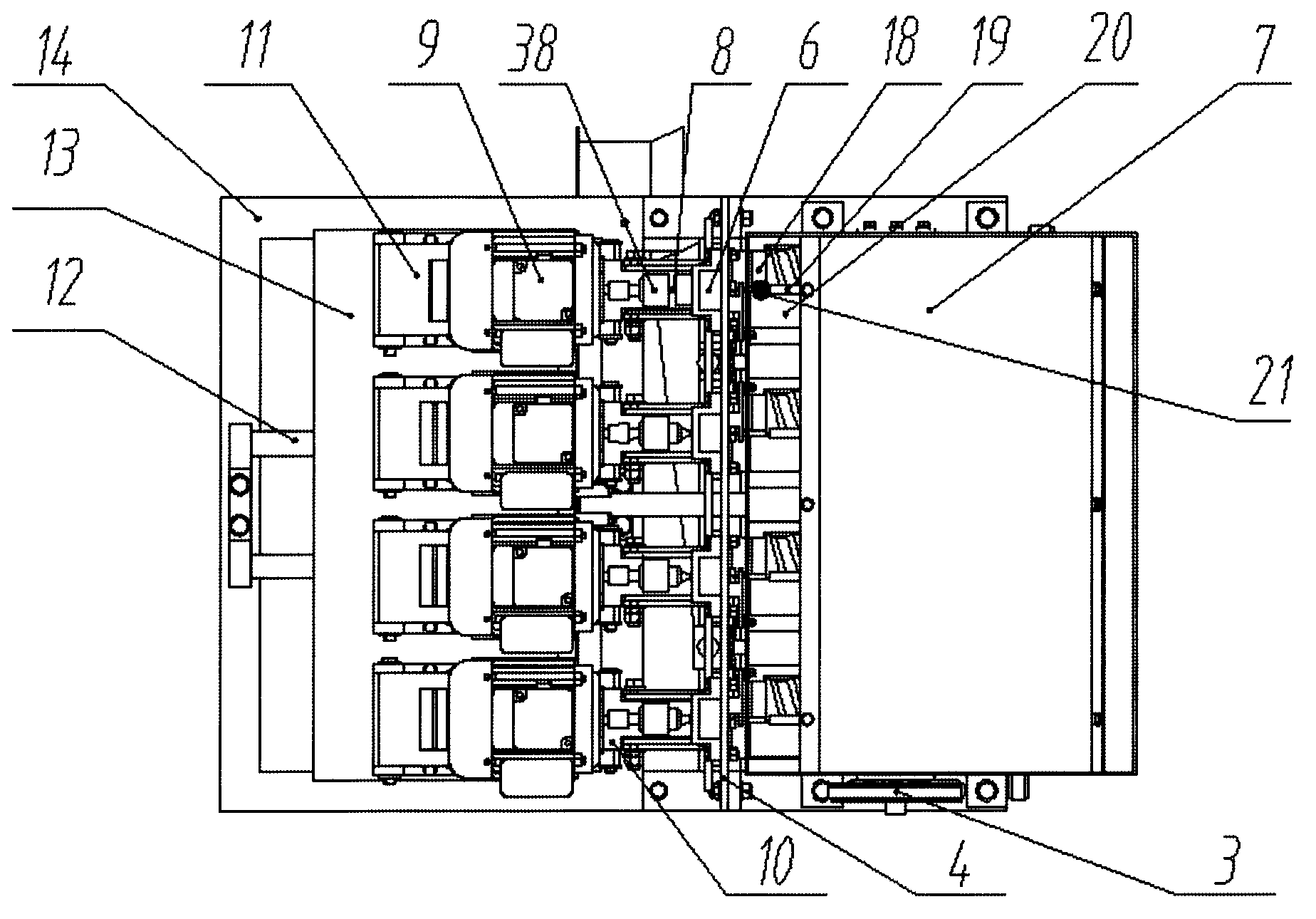

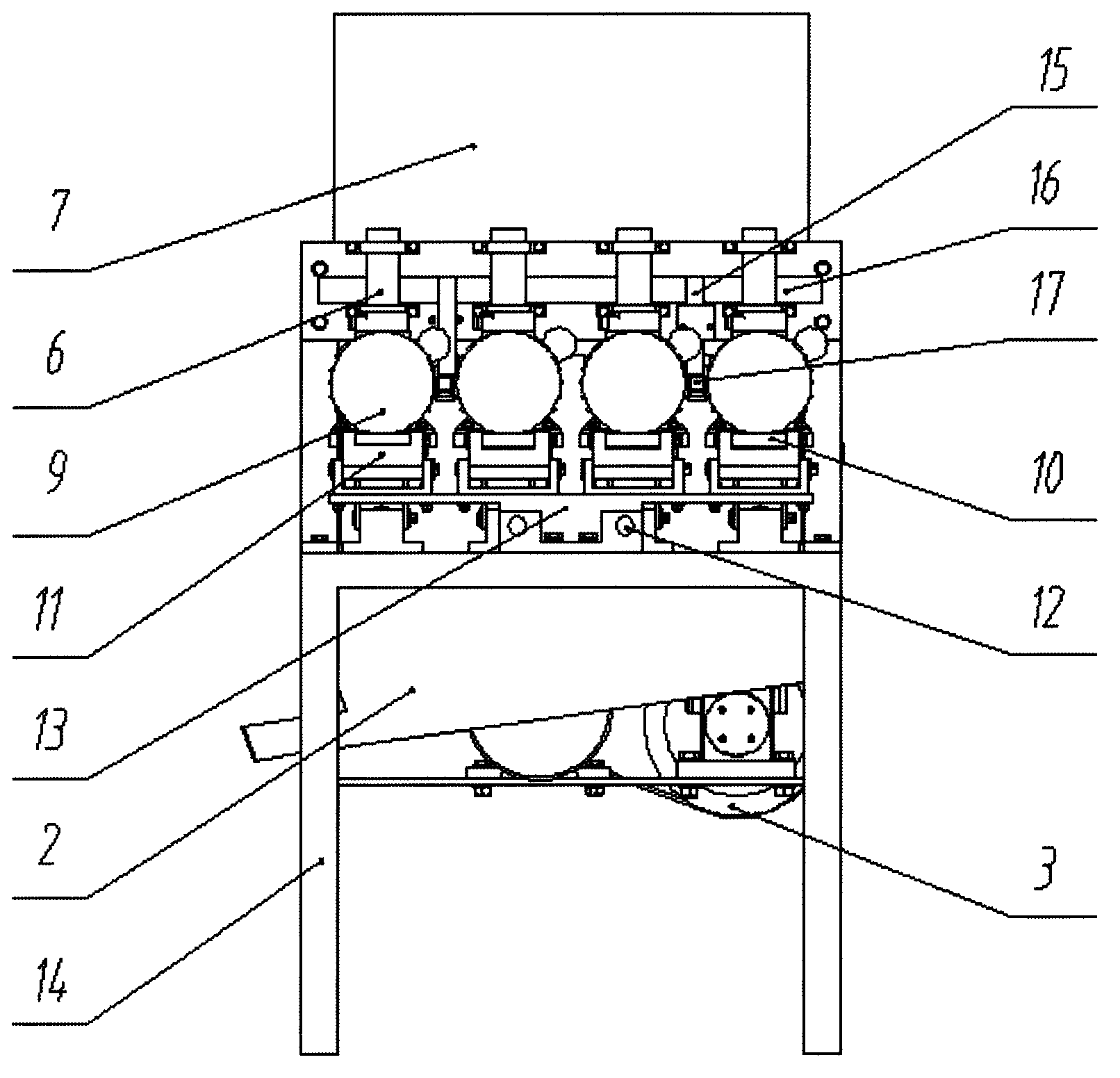

[0025] like Figure 1-Figure 9 As shown, a lotus seed coring machine that can adapt to the size of the lotus seeds in the present invention includes at least one group of coring mechanisms. The group of coring mechanisms is equipped with a guide rail 12 above the front end of the frame 14 and slides on the guide rail 12. The feed carriage 13 is installed, and the motor mounting plate 10 is installed on the feed carriage 13, and is flexibly connected by two hinged struts 11 between the feed carriage 13 and the motor mounting plate 10, and the motor mounting plate 10 is equipped with Core drilling motor 9, core drilling motor 9 axis ends are equipped with drilling core bit 8 by drill chuck 38;

[0026] A bracket 4 is installed above the middle part of the frame 14, and a crank 5 is hingedly mounted on the bracket 4. The other end of the crank 5 is hinged with one end of the connecting rod 37, and one end of the motor mounting plate 10 is hinged on the crank 5 and the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com