Sediment particle size wet screening machine

A sediment and sieving machine technology, applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of stuck mineral particles, unfavorable analysis results, sample loss, etc., and achieve easy operation, no noise, no samples loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

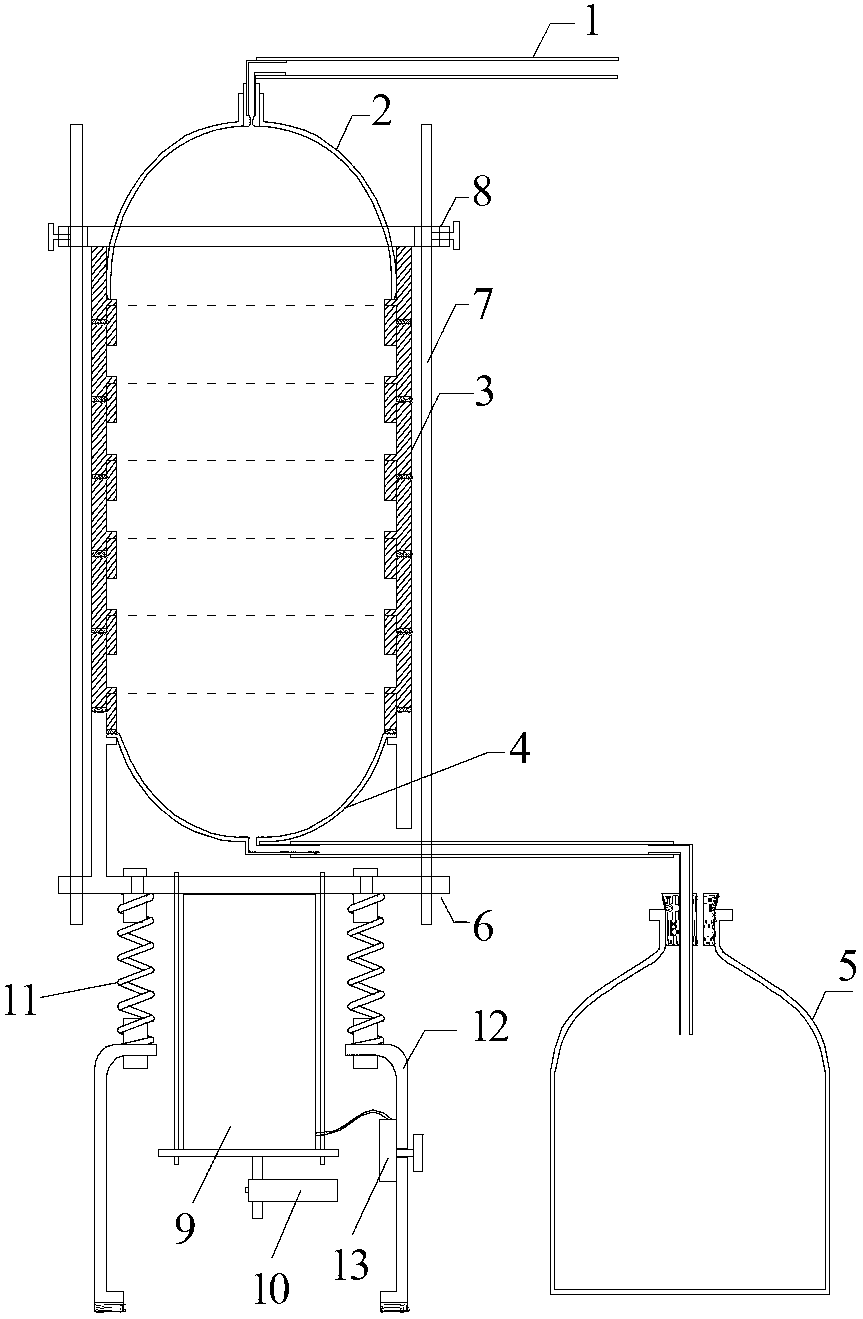

[0027] see Figure 1-10 , The embodiment of the present invention is provided with water supply pipe 1, transparent splash guard 2, graded cleaning screen 3, filtrate collector 4, filtrate collection bottle 5, dynamic vibration device, base 10 and control circuit.

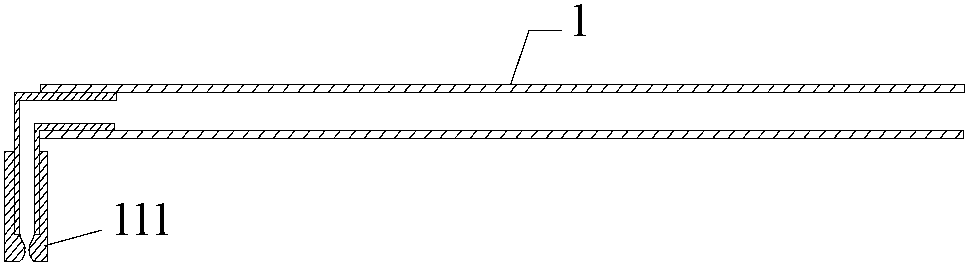

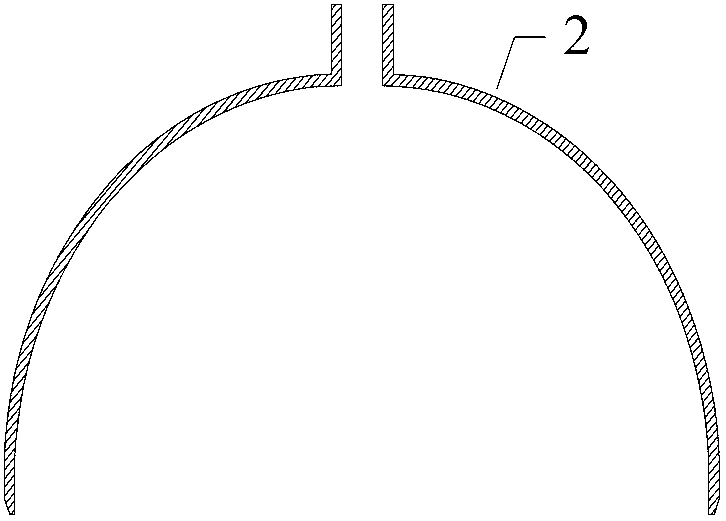

[0028] The water inlet of the water supply pipe 1 is externally connected to a water source, the water outlet of the water supply pipe 1 is connected to the upper inlet of the transparent splash guard 2, and the water outlet of the water supply pipe 1 is provided with a spray nozzle 111 . The lower end of the transparent splash guard 2 is sealed and connected to the upper end of the grading cleaning screen 3. The grading cleaning sieve 3 is equipped with 6 levels of cleaning sieves with different apertures. The frame bottom of the sieve is provided with a rubber sealing ring 31, and the apertures of the 6-stage cleaning sieve are 2.0mm, 1.0mm, 0.5mm, 0.25mm, 0.125mm, and 0.063mm from top to bottom. The upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com