Super-plastic expansion anti-oxidation program control precise loading experiment device and method

A technology of loading experiments and experimental devices, which is applied in the direction of manufacturing tools, metal processing equipment, safety equipment, etc., can solve the problems of small deformation resistance, thinning, and experimental test failures, and achieves reduced loading lag, simple operation, and improved loading. Effects of Precision and Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific content and usage method of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

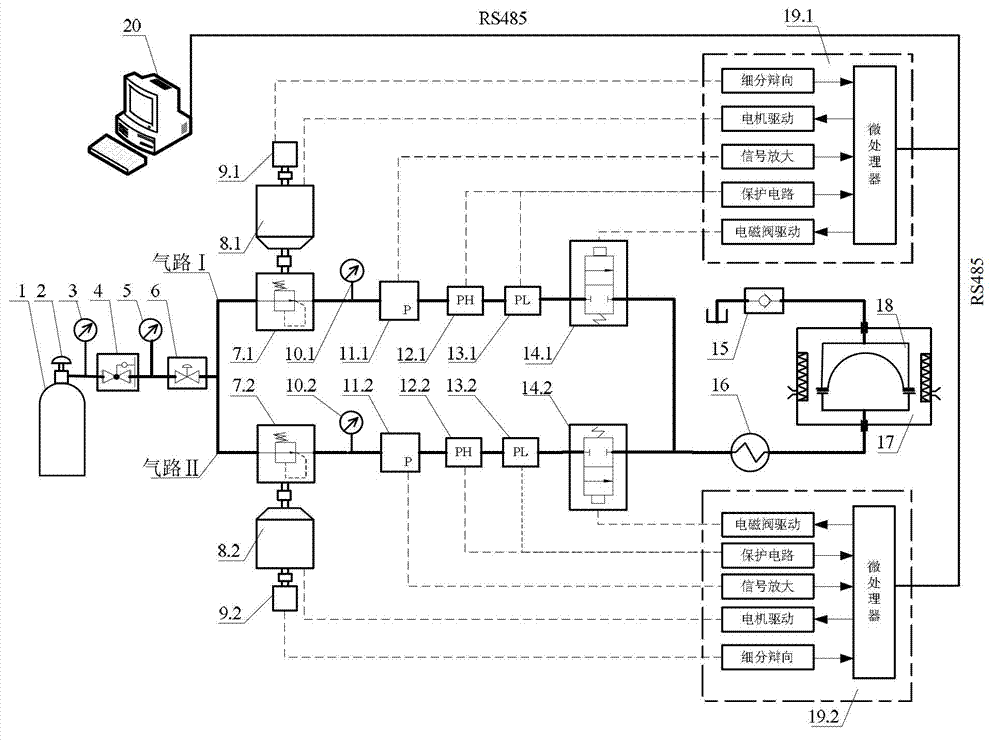

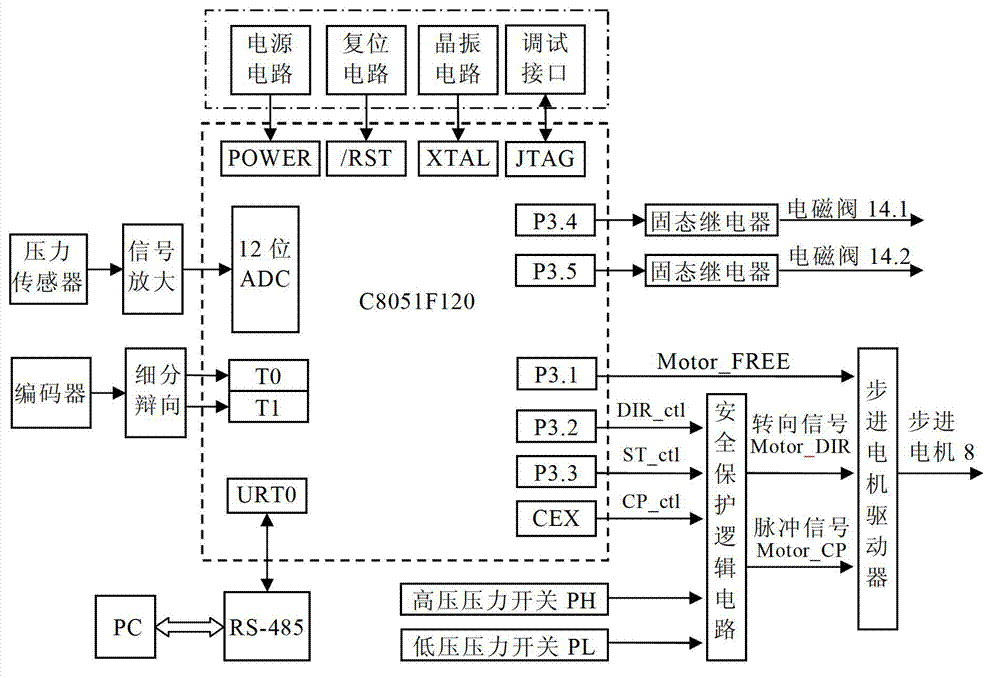

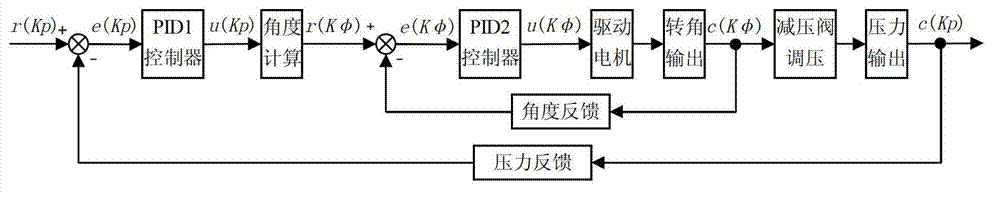

[0038] A superplastic bulging anti-oxidation program-controlled precision loading experimental device and method, the experimental device is mainly composed of an anti-oxidation gas source part, two pressure measurement and control loading gas circuits, a control system 19 and a host PC 20, the gas The source part is connected with the two-way pressure measurement and control loading air circuit, and the two-way pressure measurement and control loading air route is respectively installed on each air circuit with a precision pressure reducing valve 7, a pressure gauge C10, a pressure sensor 11 and its amplifying circuit, high and low pressure Composed of pressure switches 12, 13 and loading electromagnetic reversing valve 14, the precision decompression valve 7 is driven by a stepper motor 8, and the incremental ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com