Vacuum welding device and welding method for superconducting stack of high-temperature superconducting current lead

A current lead, high-temperature superconducting technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of slow heating and cooling, and achieve the effect of solving virtual welding, shortening the solidification time of solder, and avoiding virtual welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

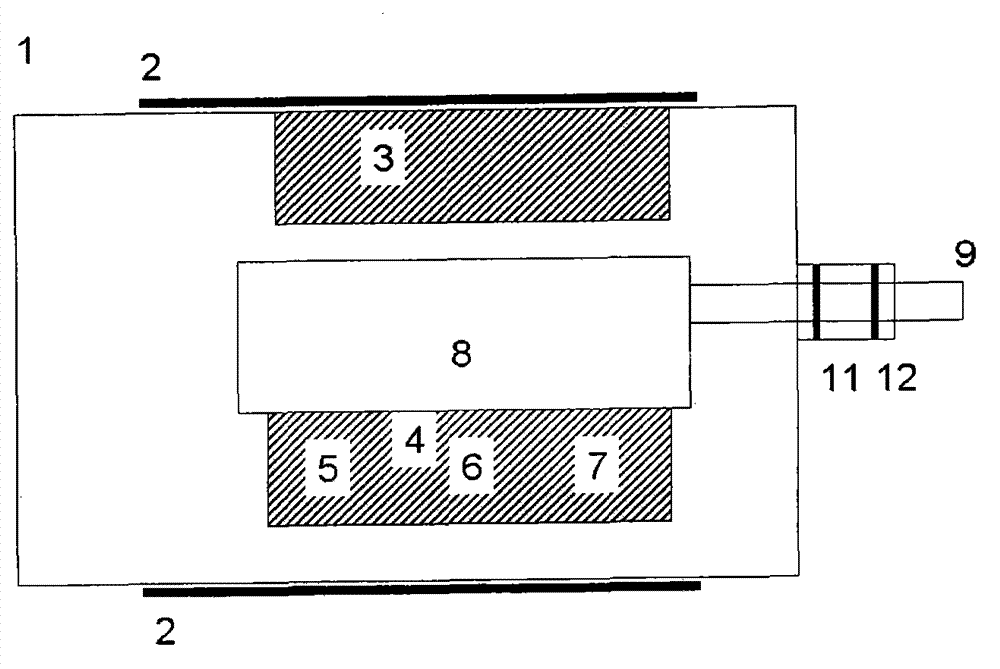

[0031] Such as figure 1As shown, a tubular vacuum chamber 1 is made of stainless steel, a heating belt 2 is wound on the outside, and a cold base 3 and a hot base 4 are respectively installed on the left and right sides of the inside. The cold base 3 is fixed with screws, and is closely attached to the inner wall of the vacuum chamber. A thin aluminum strip is placed in the middle to achieve good thermal contact. The material is aluminum. The thermal base 4 is also fixed with screws, but it is 1 cm away from the wall of the vacuum chamber to avoid thermal contact. At the same time, the part of the top of the fixing screw that contacts the thermal base is embedded with an epoxy resin gasket, so that the thermal base 4 does not directly contact the screw. Improve insulation conditions. A set of nickel-chromium alloy heating wires 5, 6, and 7 are respectively embedded in the inner head, middle, and tail of the thermal base 4, and are respectively connected to an external control...

Embodiment 2

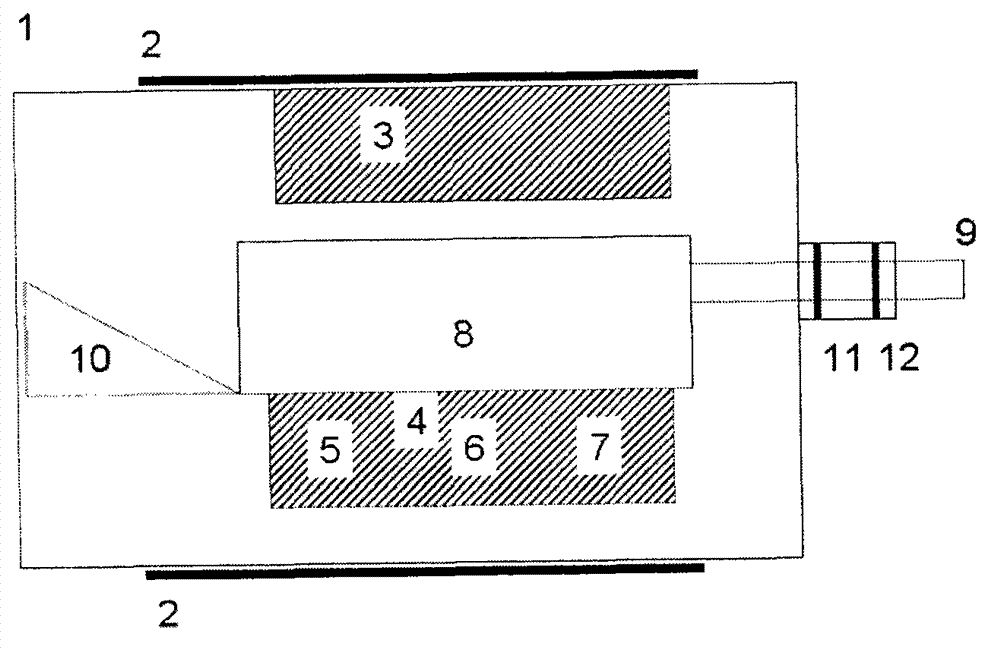

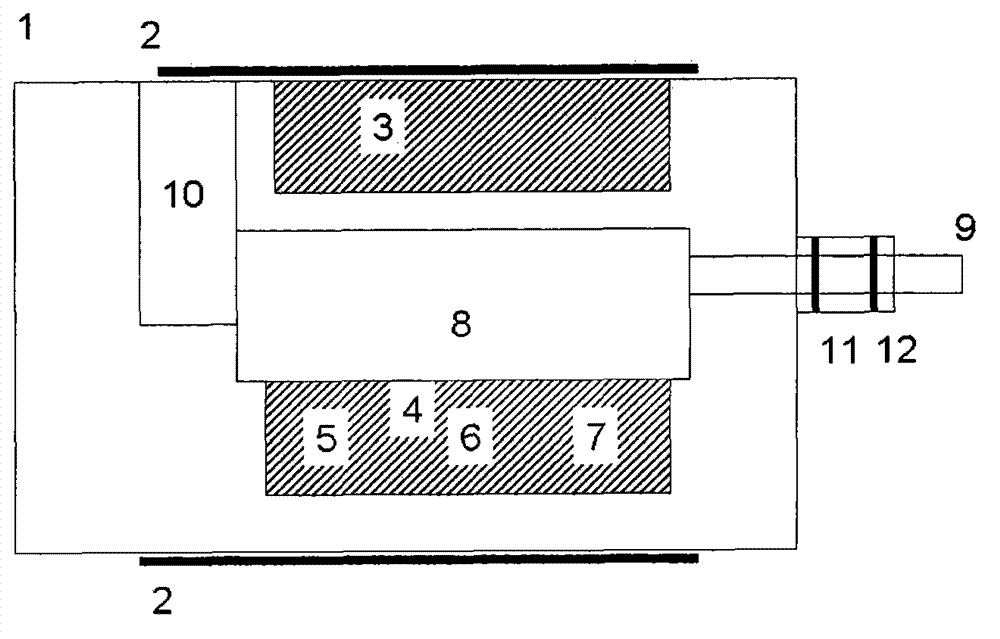

[0043] The difference between Embodiment 2 and Embodiment 1 is that the movable part is a rotating shaft 9 and is equipped with a rolling guide rail 10 . The using method of welding mold 8 is the same as embodiment 1. In the welding method, the temperature setting of the outer wall of the vacuum furnace 1 can be set at any value between 50-120°C. The setting value of the heating temperature of the thermal base 4 can exceed the melting point of the selected solder by 20-35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com