Intelligent temperature control electric soldering station

A console and electrical connection technology, applied in welding equipment, soldering irons, auxiliary devices, etc., can solve the problems of difficult to prevent damage, reduce the life of soldering iron tips, waste of electric energy, etc., achieve safe use, active adjustment effect, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

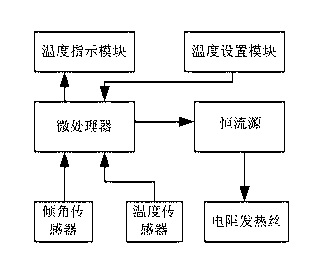

[0016] like figure 1 As shown, an intelligent temperature control welding station includes a microprocessor and a temperature indicating module connected to it, a temperature setting module, a constant current source, an inclination sensor, a temperature sensor, and a resistance heating wire. Conventional components such as soldering iron tips are in figure 1 not shown in

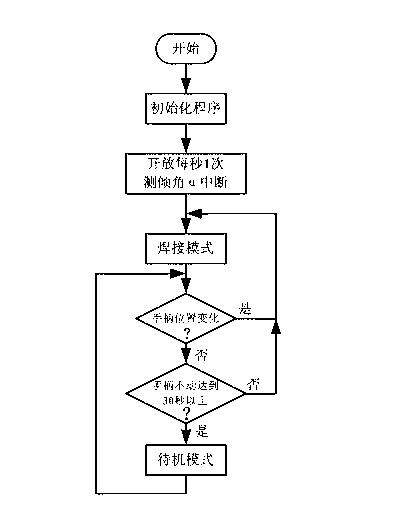

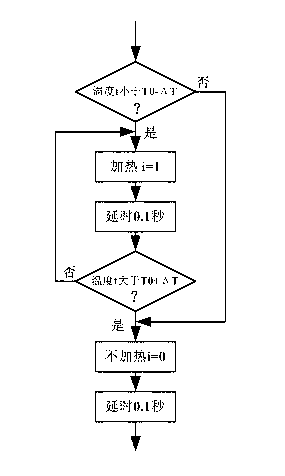

[0017] Figure 2 to Figure 5 It is the control flow chart of the present invention. The control flow of the intelligent temperature control electric welding station mainly controls the electric welding station to enter the welding mode or the standby mode by the change of the inclination angle α (provided by the inclination sensor). Considering the actual use of the welding station and various influencing factors, setting the handle of the welding station at the same position for more than N seconds (N generally takes 15 to 30) means that the welding station is not in the welding state, and the welding st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com