A method for repairing the inner wall of a dry-type thin oil-sealed gas cabinet

A gas tank and thin oil technology, which can be used in adjustable-capacity gas storage tanks, gas processing/storage purposes, gas/liquid distribution and storage, etc. To achieve the effect of reducing the compressive strength and reducing the preparation cost, the cost advantage is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

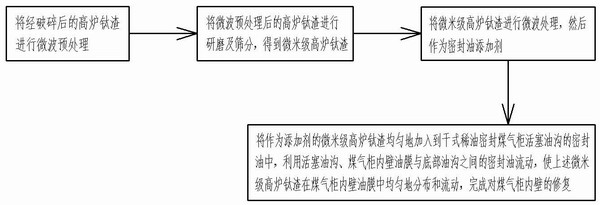

[0030] 1) The micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is used as an additive, and is evenly added to the sealing oil of the piston oil groove of the dry-type thin oil sealed gas cabinet. The sealing oil flow between the groove, the oil film on the inner wall of the gas holder and the oil groove at the bottom, so that the above-mentioned micron-sized blast furnace titanium slag is evenly distributed and flowed in the oil film on the inner wall of the gas holder, and the repair of the inner wall of the gas holder is completed. Wherein, the above-mentioned sealing oil is a lubricating oil for the sealing of dry-type thin oil sealed gas cabinets.

[0031]2) In the above step 1), the micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is as follows: after the raw material blast furnace titanium slag is crushed...

no. 2 Embodiment

[0038] 1) The micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is used as an additive, and is evenly added to the sealing oil of the piston oil groove of the dry-type thin oil sealed gas cabinet. The sealing oil flow between the groove, the oil film on the inner wall of the gas holder and the oil groove at the bottom, so that the above-mentioned micron-sized blast furnace titanium slag is evenly distributed and flowed in the oil film on the inner wall of the gas holder, and the repair of the inner wall of the gas holder is completed. Wherein, the above-mentioned sealing oil is a lubricating oil for the sealing of dry-type thin oil sealed gas cabinets.

[0039] 2) In the above step 1), the micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is as follows: after the raw material blast furnace titanium slag is crushe...

no. 3 Embodiment

[0046] 1) The micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is used as an additive, and is evenly added to the sealing oil of the piston oil groove of the dry-type thin oil sealed gas cabinet. The sealing oil flow between the groove, the oil film on the inner wall of the gas holder and the oil groove at the bottom, so that the above-mentioned micron-sized blast furnace titanium slag is evenly distributed and flowed in the oil film on the inner wall of the gas holder, and the repair of the inner wall of the gas holder is completed. Wherein, the above-mentioned sealing oil is a lubricating oil for the sealing of dry-type thin oil sealed gas cabinets.

[0047] 2) In the above step 1), the micron-sized blast furnace titanium slag obtained after crushing, microwave pretreatment, grinding, screening and microwave treatment is as follows: after the raw material blast furnace titanium slag is crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com