Automatic fluid modulation device for liquid injection forming mold

A liquid injection molding and mold technology, applied in the field of liquid injection molding mold automatic fluid modulation device, can solve the problems of modulation failure, low stability, difficult debugging, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 is a hot runner injection molding process for thermoplastic materials and a cold runner injection molding process for thermosetting materials.

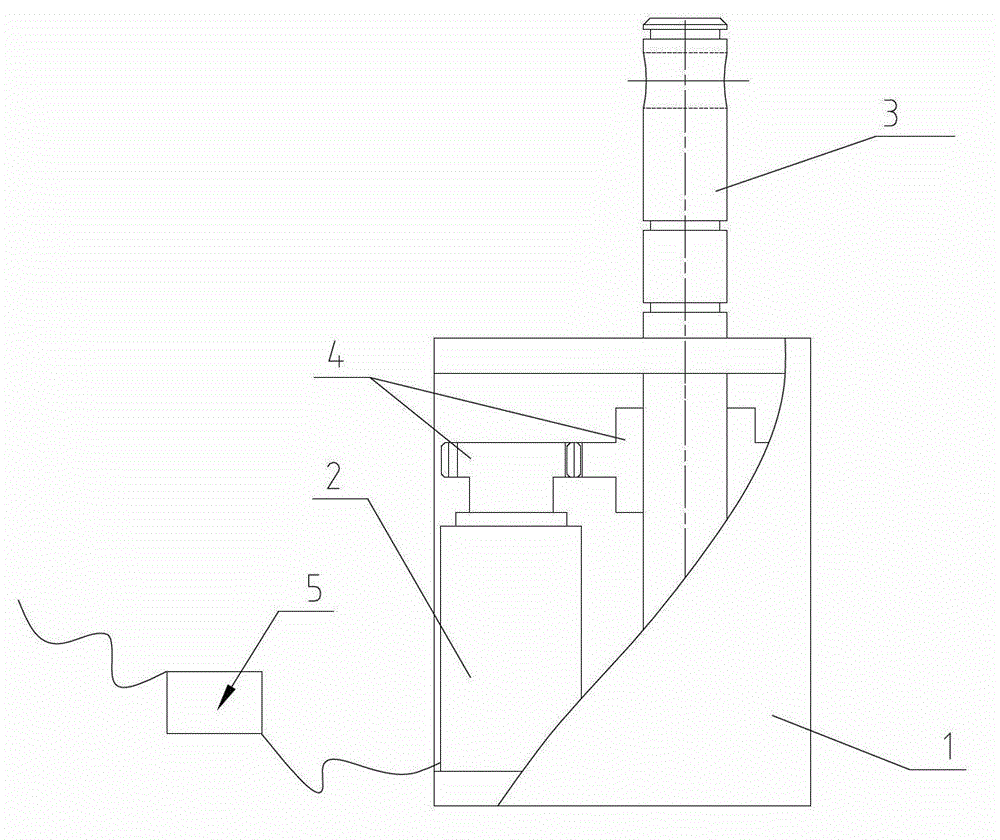

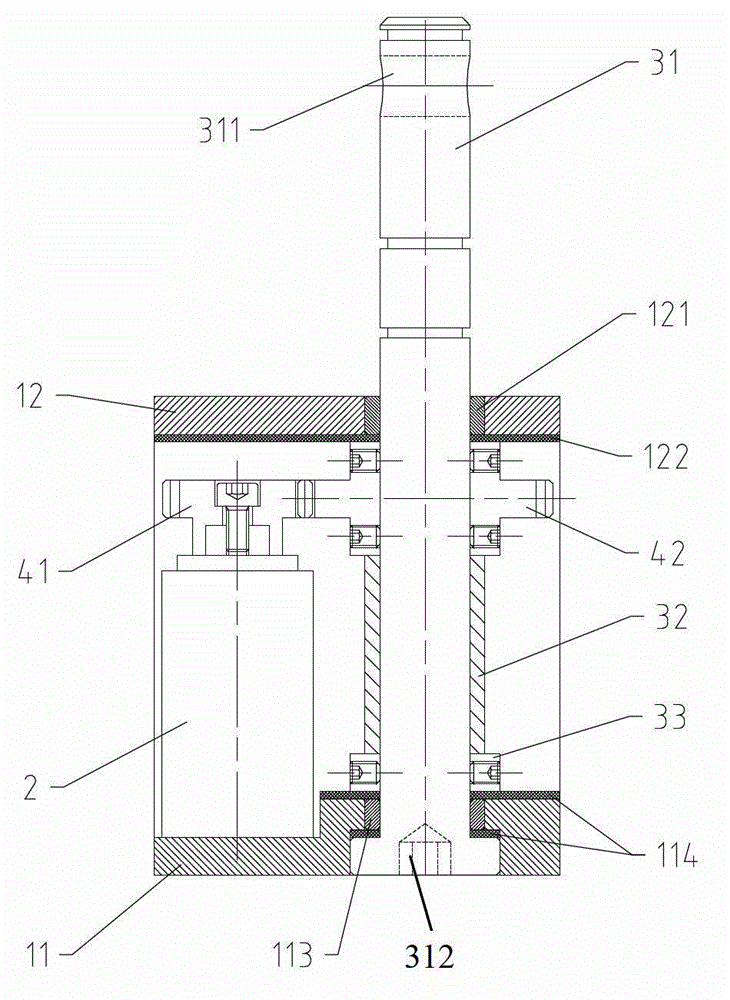

[0049] See Figure 1~3 , Example 1 is provided with a frame 1, a micro servo motor 2, a modulation valve 3, a reduction gear pair 4 and a controller 5. The micro servo motor 2 and the modulation valve 3 are fixed on the frame 1. The output end of the micro servo motor 2 is connected with the input gear 41 of the reduction gear pair 4, and the output gear 42 of the reduction gear pair 4 is set on the valve stem of the modulation valve 3. 31 on. The modulation valve 3 is provided with a valve stem 31, a sleeve 32 and a fixed retaining ring 33. The sleeve 32 and the fixed retaining ring 33 are sleeved on the lower part of the valve stem 31. The output terminal of the controller 5 is connected to the micro servo motor 2, and the input terminal of the controller 5 is connected to the sensor on the injection molding machine ...

Embodiment 2

[0068] See Figure 4 , Similar to embodiment 1, the difference is that the valve hole 311 at the upper end of the valve stem 31 in the embodiment 1 (see figure 2 ) Is changed to U-shaped groove 311' (it can also be other open valve ports with different fluid characteristics).

[0069] This embodiment 2 is suitable for the cold runner injection molding process of ordinary thermoplastic materials. The specific application and installation methods are as follows:

[0070] See Figure 5 This embodiment 2 is installed on the mold support plate P2 of the mold. During injection, the valve stem 31 rotates a certain angle to modulate the fluid. After the injection stage, the valve stem 31 rotates back, so as to avoid the flow channel condensation There is a weak link in the material (that is, the position where the valve port and the runner intersect), and the product and the gate condensate can be smoothly ejected by the thimble P1. Figure 5 In, mark P4 is the reset rod of the mold, and t...

Embodiment 3

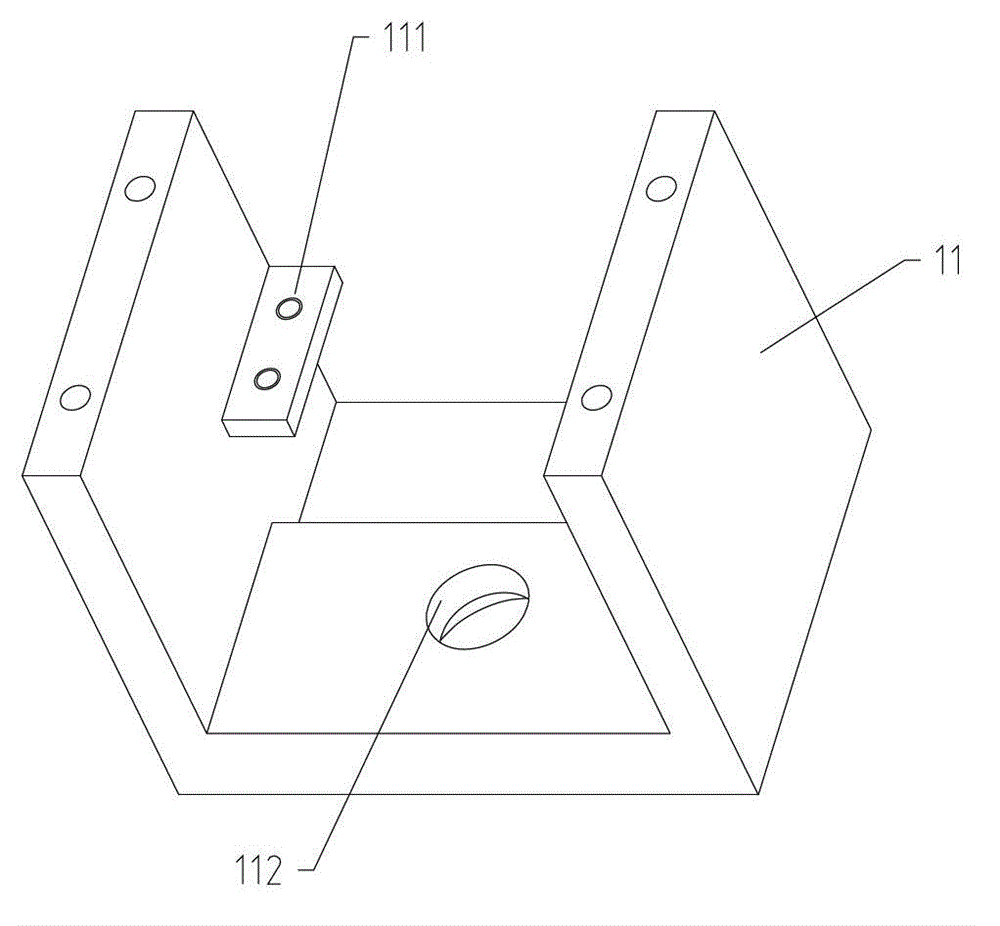

[0073] See Figure 7 with 8 Similar to Embodiment 1, the difference is that Embodiment 3 is suitable for occasions where the required torque is relatively large, and an upper miniature planar thrust ball bearing 123 and a lower miniature planar thrust ball bearing 115 are added to the valve stem 31. The miniature plane thrust ball bearing can effectively prevent the valve stem 31 from moving axially. The D-shaped limit flange at the bottom end of the valve stem 31 and its matching form with the countersunk limit hole 112 are as follows Picture 8 Shown. The rest mark with figure 2 correspond. The installation method and working process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com