Halogen-free heat-proof low-smoke and flame-retardant polyester compound and preparation method thereof

A technology of flame-retardant polyester and compound, which is applied in the field of halogen-free heat-resistant low-smoke flame-retardant polyester compound and its preparation, can solve the problems of low heat resistance and no good fluidity, and achieve less smoke generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

[0019] Below in conjunction with embodiment, the present invention is further described:

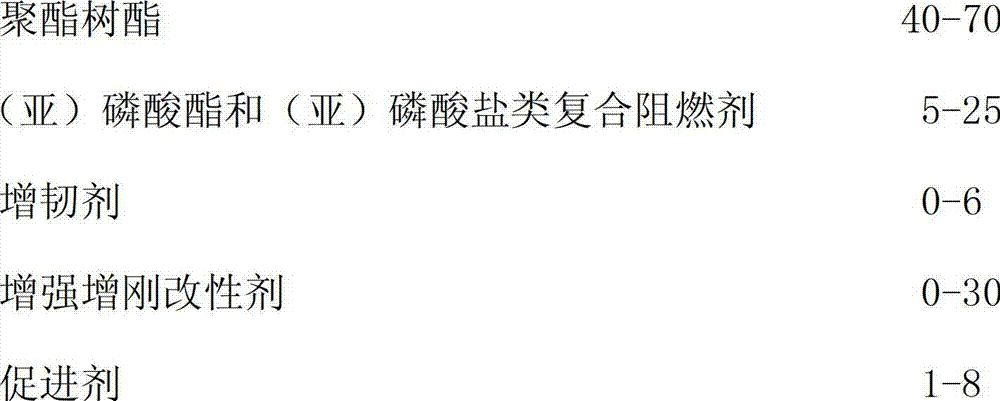

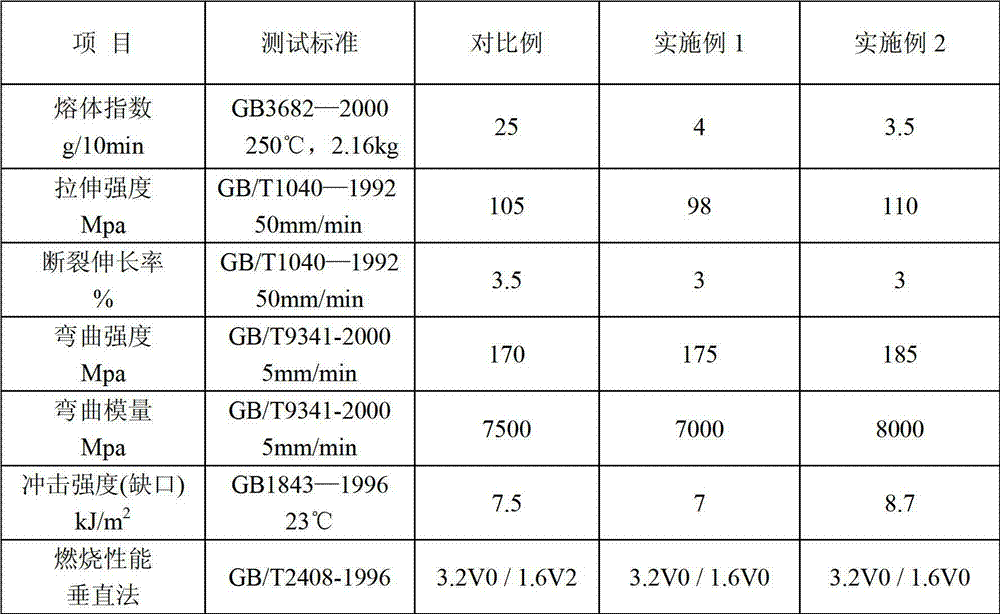

[0020] Using 1-2 kinds of polyester as the base material to add (phosphite) and (phosphite) compound flame retardants, tougheners, reinforcing modifiers, accelerators, additives (lubricants, heat stabilizers) , anti-UV agent, pigment, nucleating agent, coupling agent, release agent, anti-dripping agent), the feeding ratio is as shown in Table 1:

[0021] Table 1 A halogen-free heat-resistant low-smoke flame-retardant polyester compound

[0022] ingredients

comparative example

Example 1

Example 2

polyester (1)

46.7

35.8

35.8

Polyester (2)

---

10

10

8

4

4

---

4

4

Phenoxyphosphorus cyanide

7

3

3

Phenoxypolyphosphorcyanate

---

4

4

1125AC

2.5

2.5

2.5

Toughener (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com