Environment-friendly vulcanizing material modifier for drainage asphalt roads and preparation method thereof

A technology of drainage asphalt and modifier, which is applied in the direction of building insulation materials, building components, buildings, etc., and can solve the problems of uneconomical, inconvenient, uneconomical, and increased raw material consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

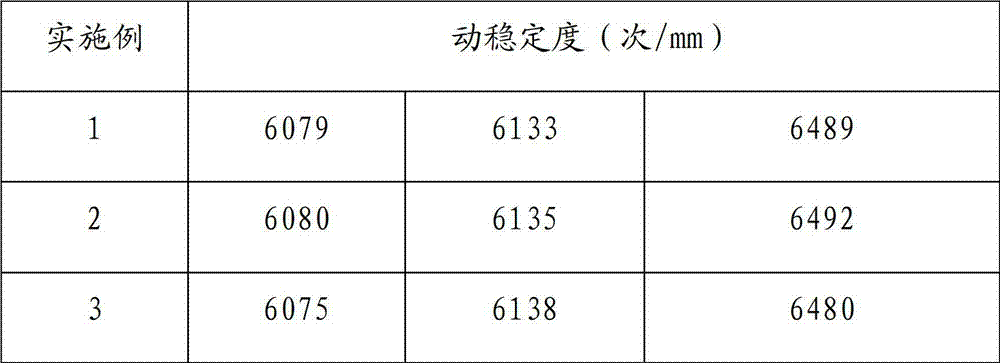

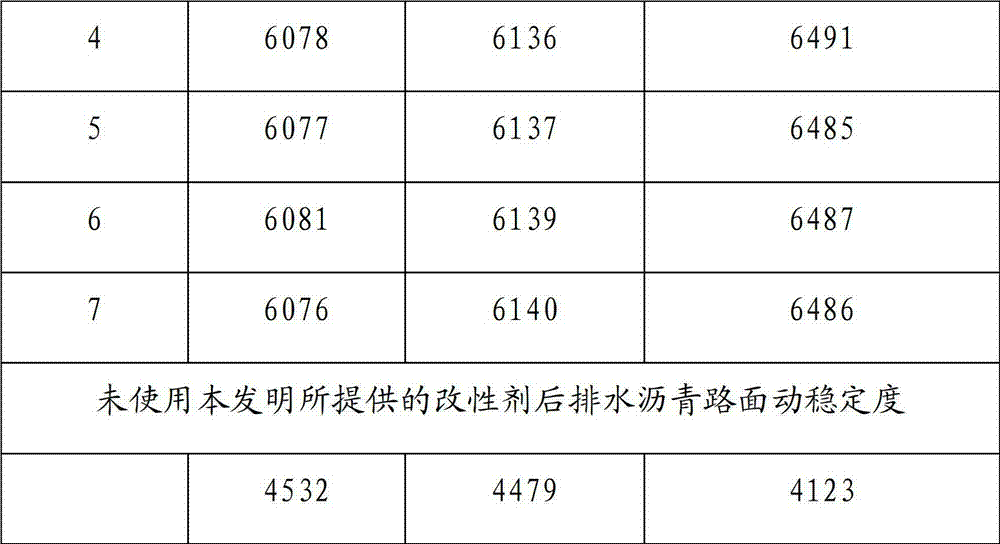

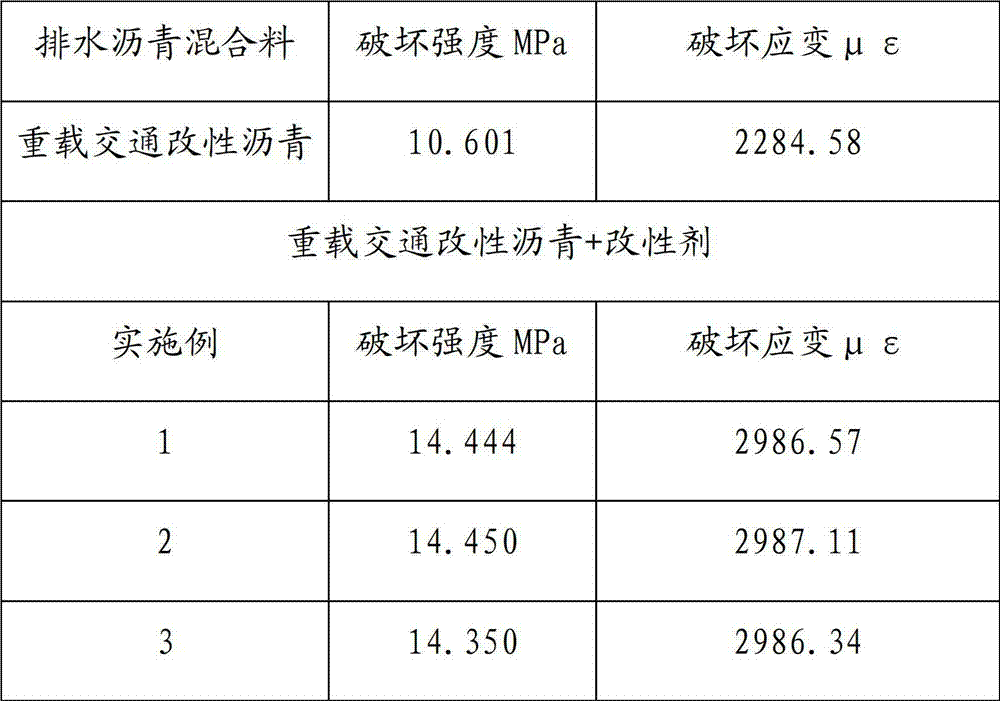

Examples

preparation example Construction

[0028] Simultaneously, the present invention also provides a kind of preparation method of the environment-friendly hot-fill material modifier that is used for drainage asphalt pavement, and described method comprises the following steps:

[0029] A. Add 10-20 parts by weight of rock bitumen to the reactor, preheat the reactor to 130-160°C, and stir for 5-10 minutes;

[0030] B. Heat up the reaction kettle to 170-190°C, add 10-20 parts by weight of rubber powder, and stir for 60-120 minutes;

[0031] C. Gradually lower the temperature to 140-160°C, add 30-500 parts by weight of polyester and 0.1-1 part by weight of tackifier in turn, and stir for 20-40 minutes to obtain a mixture containing rubber powder, polyester, and tackifier. Mixture with rock bitumen;

[0032] D. After the mixing is completed, the mixture is injected into the extruder, sheared and water-cooled to granulate, and the finally obtained granules are the environmental-friendly hot-fill modifier for drainage a...

Embodiment 1

[0036]Add 50 parts by weight of rock asphalt with a bitumen content of 30% to the reactor, preheat to 150°C, and stir rapidly for 40 minutes; then raise the temperature of the reactor to 180°C, and load 20 parts by weight of rubber powder with a particle size of 60 mesh, Stir rapidly for 80 minutes; then wait for the reaction kettle to cool down naturally to 140°C, then add 0.1 parts by weight of tackifier SBS and 30 parts by weight of polyester polymethyl methacrylate in sequence, and stir rapidly for 30 minutes; after the final stirring is completed, put The mixture is injected into a twin-screw extruder, sheared and water-cooled to granulate. The prepared particles are not only an environment-friendly hot-fill modifier for drainage asphalt pavement.

Embodiment 2

[0038] Add 75 parts by weight of rock asphalt with a bitumen content of 40% to the reactor, preheat to 160°C, and stir rapidly for 50 minutes; then raise the temperature of the reactor to 180°C, and load 10 parts by weight of rubber powder with a particle size of 80 mesh, Stir rapidly for 70 minutes; then wait for the reaction kettle to cool down naturally to 150°C, then add 1 part by weight of tackifier SBS and 100 parts by weight of polyester polyethyl methacrylate in sequence, and stir rapidly for 40 minutes; after the final stirring is completed, pour the mixture into Single-screw extruder, shear water-cooled granulation. The prepared particles are not only an environment-friendly hot-fill modifier for drainage asphalt pavement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com