Special paper for external standard of cup bowl and manufacturing technology thereof

A special paper and external standard technology, applied in the field of paper making, can solve problems such as food safety hazards, low stiffness of gray-bottomed whiteboard paper and low bonding force between paper layers, and inability to meet the requirements for fluorescent substance control of food paper, so as to eliminate safety Hidden dangers, the effect of improving packaging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

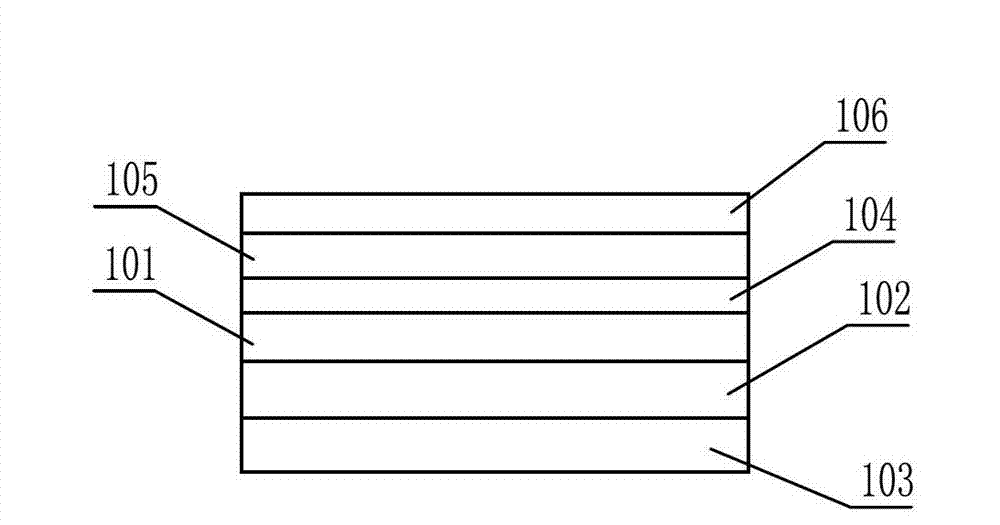

[0046] Take the external standard special paper for cups and bowls with a basis weight of 210 g / m2 as an example.

[0047] Surface layer pulp: 70% bleached hardwood kraft pulp and 30% bleached softwood kraft pulp are proportioned by weight.

[0048] Core layer pulp: 50% bleached chemithermomechanical pulp, 25% bleached softwood kraft pulp, and 25% broke paper by weight.

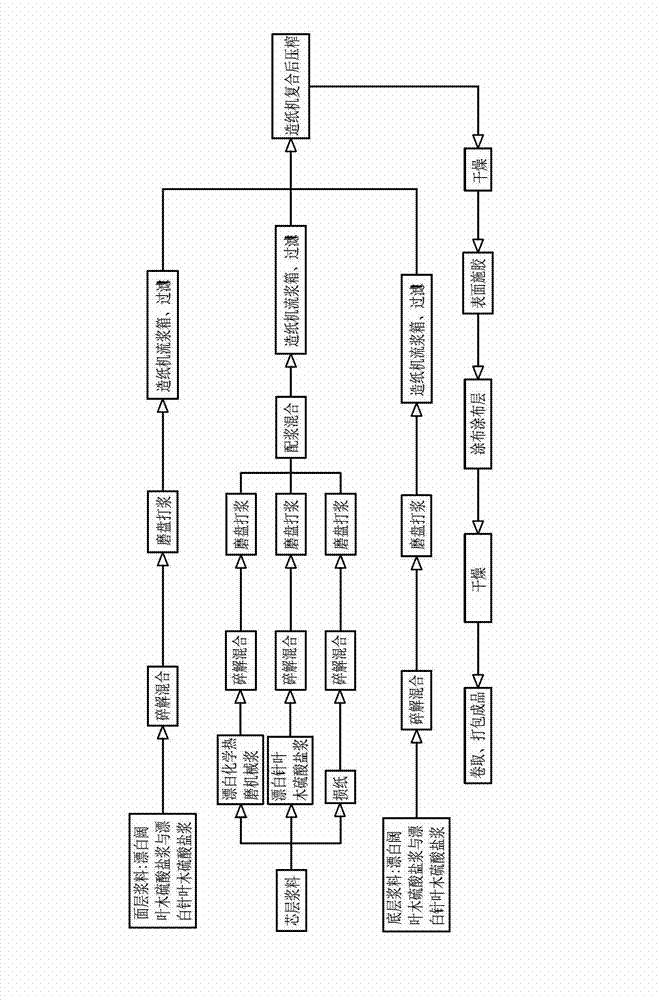

[0049] The bleached chemithermomechanical pulp is disintegrated, mixed, disc-refined and beaten;

[0050] The bleached softwood kraft pulp is disintegrated, mixed, disc-milled and beaten;

[0051] The broken paper is disintegrated, mixed, disc-refined and pulped;

[0052] Then, the bleached chemithermomechanical pulp, the bleached softwood kraft pulp, and the broke pulp are mixed, and then enter the headbox of the paper machine for filtration.

[0053] Bottom layer pulp: 90% bleached hardwood kraft pulp and 10% bleached softwood kraft pulp by weight are proportioned.

[0054]Then, it is pressed by a paper...

Embodiment 2

[0058] Take the external standard special paper for cups and bowls with a basis weight of 250 g / m2 as an example.

[0059] The production process of this embodiment is the same as that of the above-mentioned first embodiment, and the difference lies in: the slurry ratio of the surface layer slurry, the core layer slurry, and the bottom layer slurry.

[0060] In this embodiment, the surface layer pulp: 80% bleached hardwood kraft pulp and 20% bleached softwood kraft pulp by weight are proportioned.

[0061] Core layer pulp: 52% bleached chemithermomechanical pulp, 16% bleached softwood kraft pulp, and 32% broke paper by weight.

[0062] Bottom pulp: 80% bleached hardwood kraft pulp and 20% bleached softwood kraft pulp by weight.

[0063] The performance indicators of the gray-backed whiteboard paper with a basis weight of 250 g / square meter on the market and the special paper for cups and bowls with a basis weight of 250 g / square meter described in this example are as follows:...

Embodiment 3

[0066] Take the external standard special paper for cups and bowls with a basis weight of 350 g / m2 as an example.

[0067] The production process of this embodiment is the same as the above-mentioned first and second embodiments, the difference lies in: the slurry ratio of the surface layer slurry, the core layer slurry, and the bottom layer slurry.

[0068] In this embodiment, the surface layer pulp: 90% bleached hardwood kraft pulp and 10% bleached softwood kraft pulp by weight percentage.

[0069] Core layer pulp: 55% bleached chemithermomechanical pulp, 5% bleached softwood kraft pulp, and 40% broke paper by weight.

[0070] Bottom pulp: 70% bleached hardwood kraft pulp and 30% bleached softwood kraft pulp by weight.

[0071] The performance indicators of the gray-backed whiteboard paper with a basis weight of 350 g / square meter on the market and the external standard special paper for cups and bowls with a basis weight of 350 g / square meter described in this example are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com