Anti-pulling system

An anti-pulling and parallel installation technology, applied in building components, shock-proof and other directions, can solve the problems of endangering the personal safety of buildings, large acceleration and displacement, panic and anxiety, etc., to prolong the service life, ensure safety, and restrain tilt or shaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

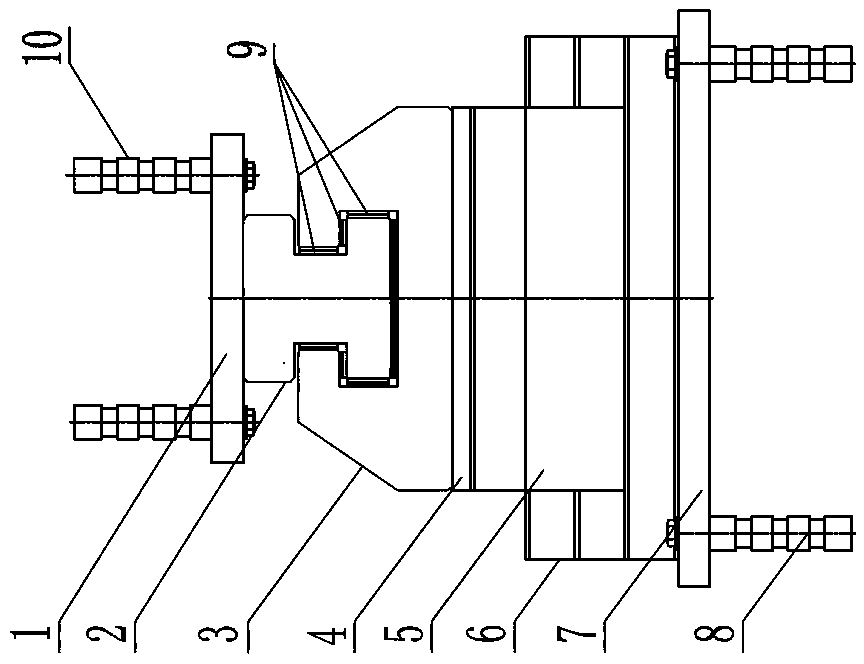

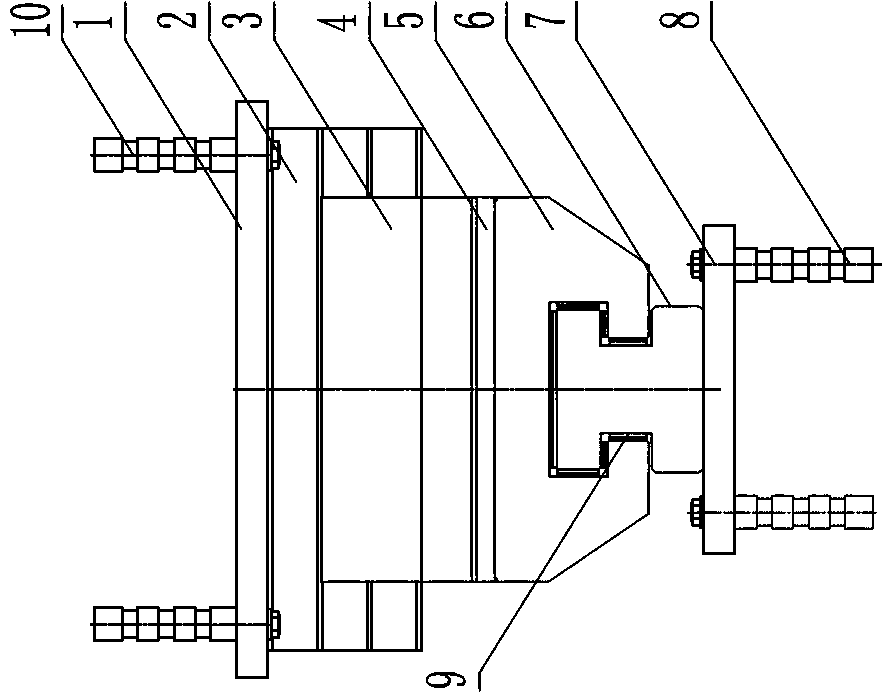

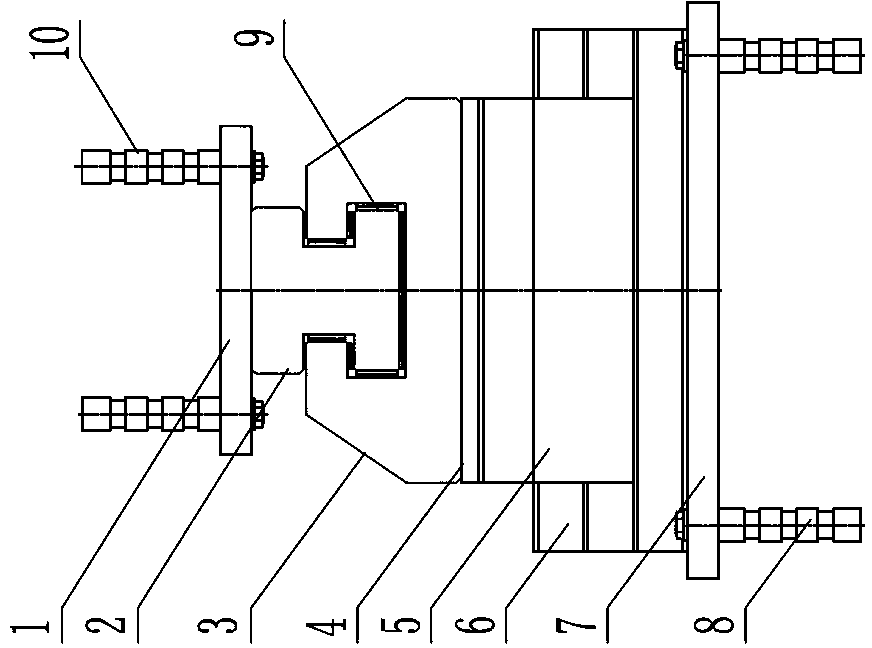

[0035] one A kind of anti-pullout device, comprises upper and lower connecting plate, the upper layer sliding mechanism and the lower layer sliding mechanism that are respectively connected with upper and lower connecting plate, and the middle layer 4 that is connected between the upper layer sliding mechanism and the lower layer sliding mechanism, the upper layer The sliding mechanism has the same structure as the lower sliding mechanism, installed with the back facing, and the sliding directions are perpendicular to each other.

[0036] The upper sliding mechanism includes a set of upper guide rails 2 installed in parallel and an upper slider 3 that is slidably matched with the upper guide rails, and the lower sliding mechanism includes a set of lower guide rails 6 installed in parallel and a lower slider that is slidably matched with the lower guide rails 5. The top surface of the upper guide rail 2 is connected to the upper connection plate 1, the top surface of the lower ...

Embodiment 2

[0040] one A kind of anti-pullout device, its basic structure is identical with embodiment one, comprises upper and lower connecting plate, the upper layer sliding mechanism and the lower layer sliding mechanism that are connected with upper and lower connecting plate respectively, and be connected with the upper layer sliding mechanism and the lower layer sliding mechanism Between the intermediate layer 4, the upper sliding mechanism and the lower sliding mechanism have the same structure, are installed with their backs facing each other, and the sliding directions are perpendicular to each other.

[0041] The difference is that the upper sliding mechanism includes a set of upper guide rails 2 installed in parallel and the upper slider 3 slidingly matched with the upper guide rails, and the lower sliding mechanism includes two sets of lower guide rails 6 installed in parallel and sliding with the lower guide rails. Cooperating with the lower slider 5, the top surface of the u...

Embodiment 3

[0044] one A kind of anti-pullout device, its basic structure is identical with embodiment one, comprises upper and lower connecting plate, the upper layer sliding mechanism and the lower layer sliding mechanism that are connected with upper and lower connecting plate respectively, and be connected with the upper layer sliding mechanism and the lower layer sliding mechanism Between the intermediate layer 4, the upper sliding mechanism and the lower sliding mechanism have the same structure, are installed with their backs facing each other, and the sliding directions are perpendicular to each other.

[0045] The difference is that the upper sliding mechanism includes 2 sets of upper guide rails 2 installed in parallel and the upper slider 3 slidingly matched with the upper guide rails, and the lower sliding mechanism includes 2 sets of lower guide rails 6 installed in parallel and sliding with the lower guide rails. Cooperating with the lower slider 5, the top surface of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com