Steel plate and high-strength concrete combined shear wall

A combined shear wall and high-strength concrete technology, applied in the direction of walls, building components, and earthquake resistance, can solve the problems of reducing the seismic performance, tensile and shear strength of high-strength concrete structures, and low coarse aggregate strength and ductility. The effect of improving ultimate shear bearing capacity, good social and economic benefits, ductility and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

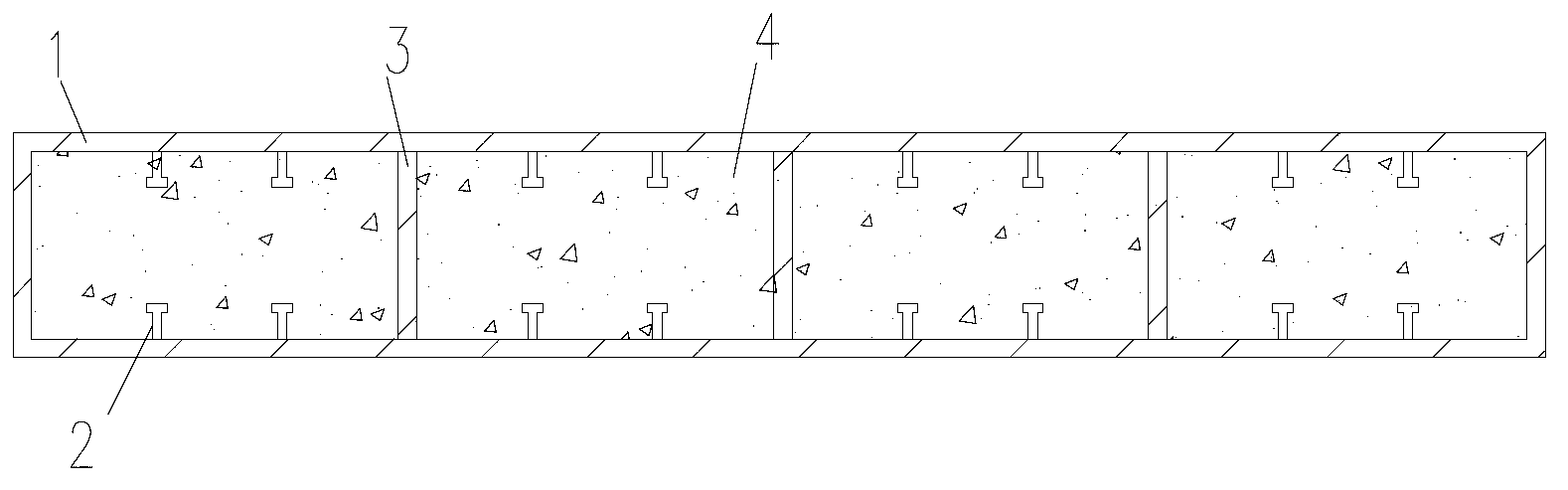

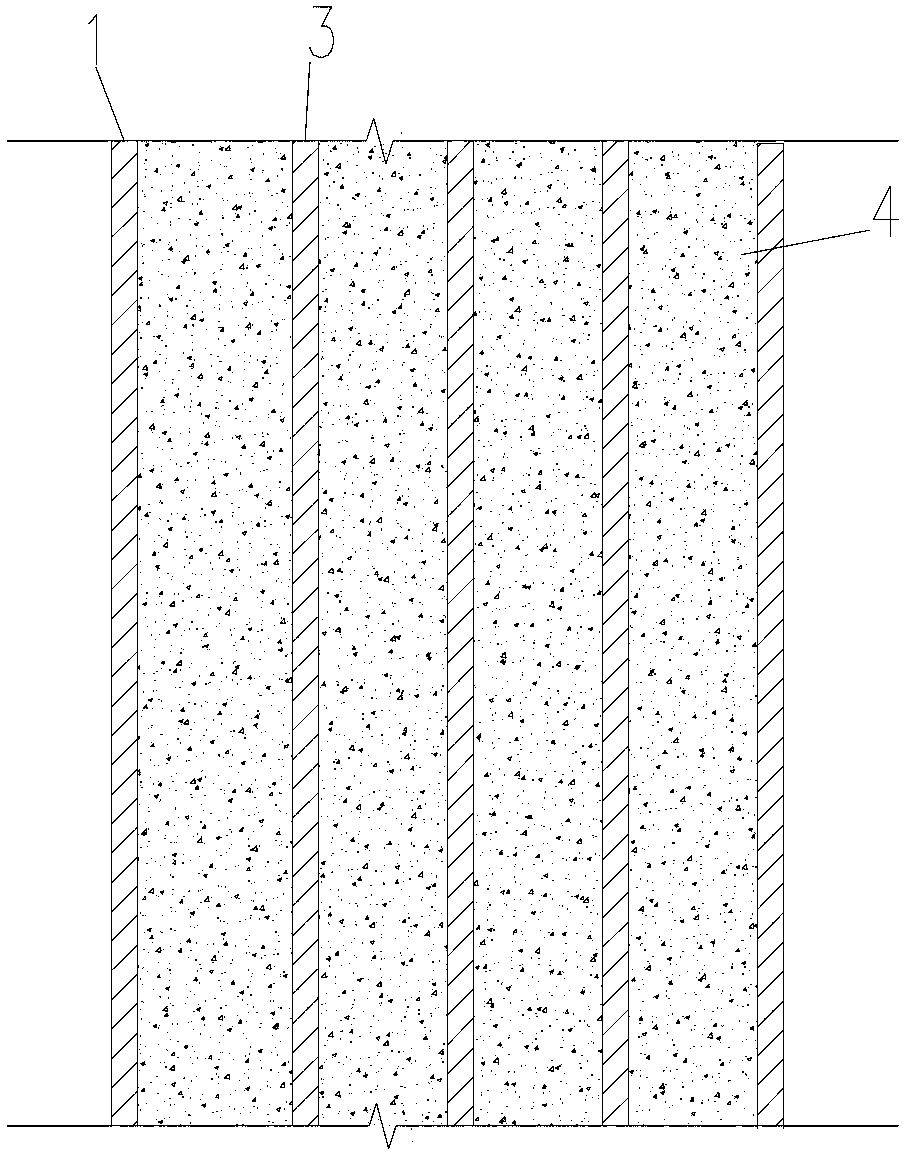

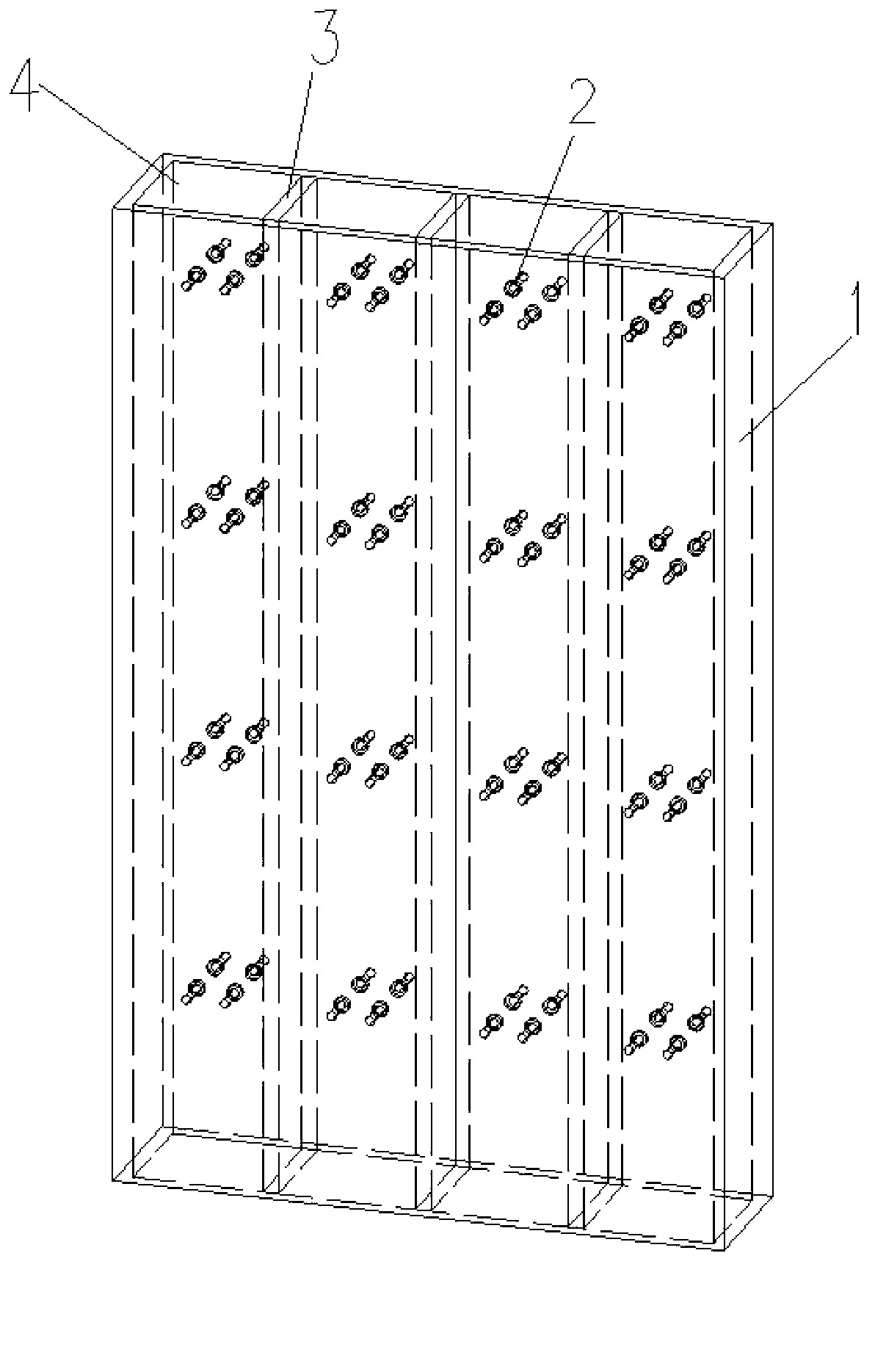

[0025] A new type of steel-concrete composite shear wall with a stiffening plate between the steel plates on both sides, that is, a multi-cavity steel plate-high-strength concrete composite shear wall, including an outer double-layer steel plate with a stiffening steel plate and a concrete shear wall. Pour high-strength concrete (above C60) in the outer double-layer steel plate with stiffened steel plate, and the concrete and the steel plate are connected by bolts. The outsourcing double-layer steel plate is surrounded by four thin steel plates on four sides to form an outsourcing formwork that completely wraps the concrete. The stiffening steel plates are arranged between the steel plates on both sides of the shear wall, penetrate from top to bottom in the steel plates on both sides, the stiffening steel plates are welded on the steel plates on both sides, and the stiffening steel plates are perpendicular to the steel plates on both sides. The stiffening steel plates separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com