In-situ stress testing method of method for relieving stress in original hole site for multiple times

A stress relief method and stress relief technology are applied in the field of research on the distribution state of the original rock stress field in the deep part of the surrounding rock of the roadway. Economic benefits, saving manpower and material resources, reducing the effect of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

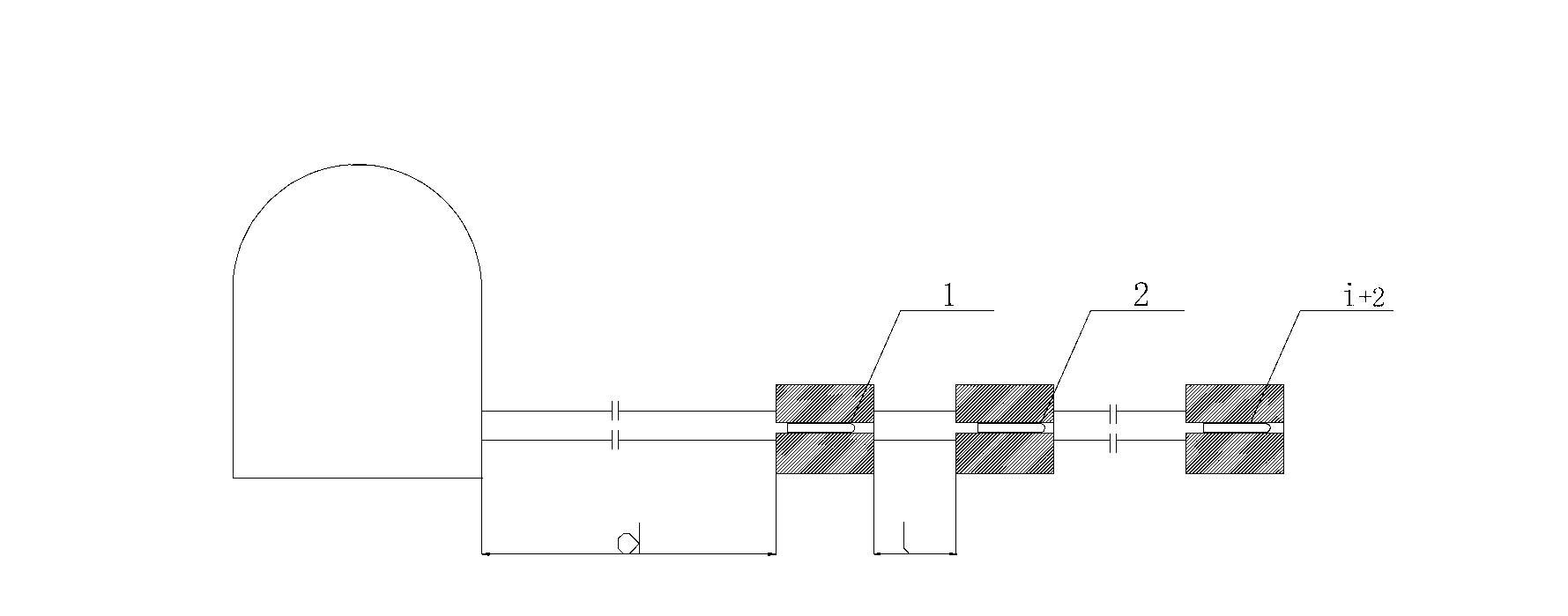

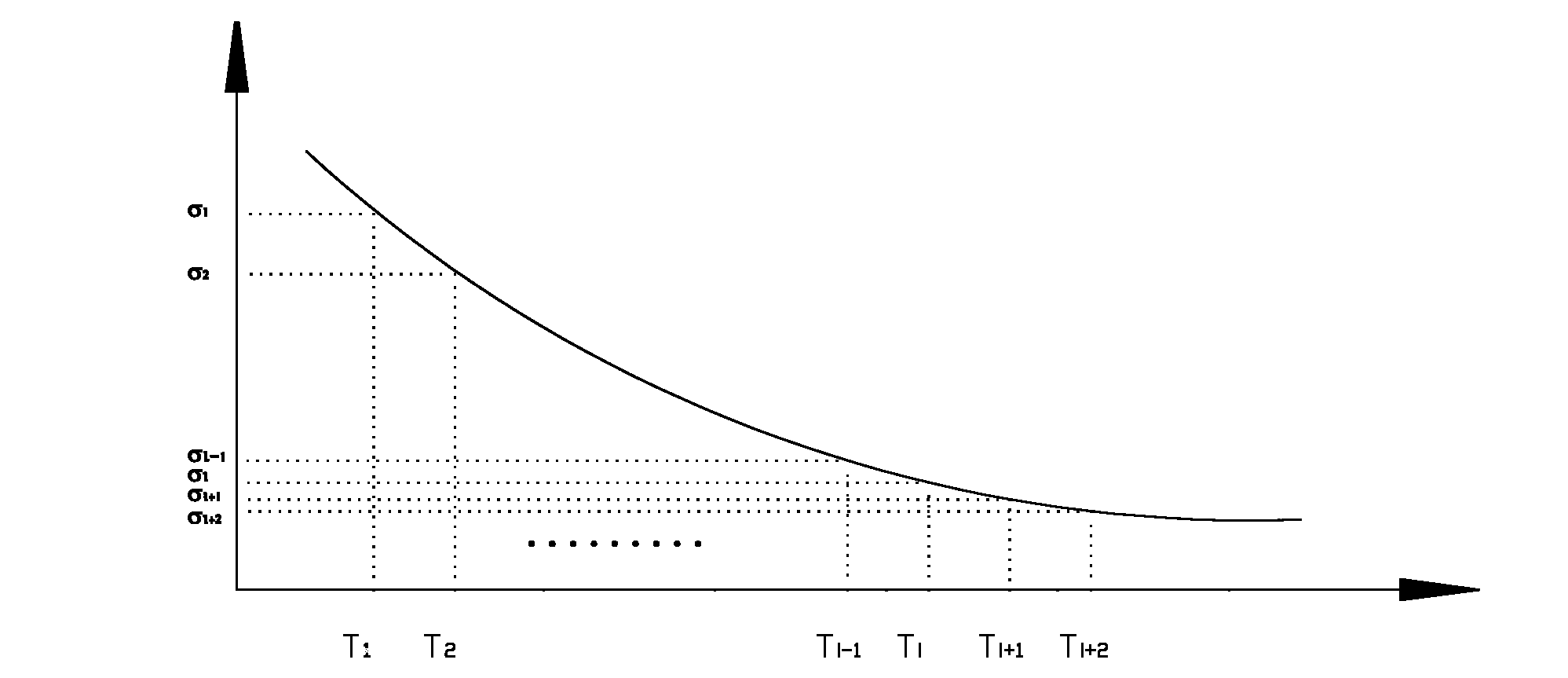

[0014] In the present embodiment, the specific operation steps of the ground stress test for a kind of original hole position multiple ground stress relief method are as follows: see figure 1 and figure 2 ,

[0015] 1. Select a suitable measuring point, and use the SGM-1A geological drilling rig to drill a large hole with a diameter of 127mm and a depth of 10m into the interior of the rock mass from the surface of the rock mass. In order to facilitate the installation of the test probe in the next step, the large hole must maintain a certain degree of concentricity, so a guiding device is required during the drilling process, and the bottom of the hole needs to be ground flat after the large hole is drilled.

[0016] 2. Use a tapered drill bit to make a bell mouth, and then drill a small hole with a concentric diameter of 37mm from the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com