Damping support device

A vibration-absorbing support and support technology, applied in the direction of spring/shock absorber, non-rotation vibration suppression, wind turbine components, etc., can solve the problems of small adjustment amount, erosion, lack of adjustment mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

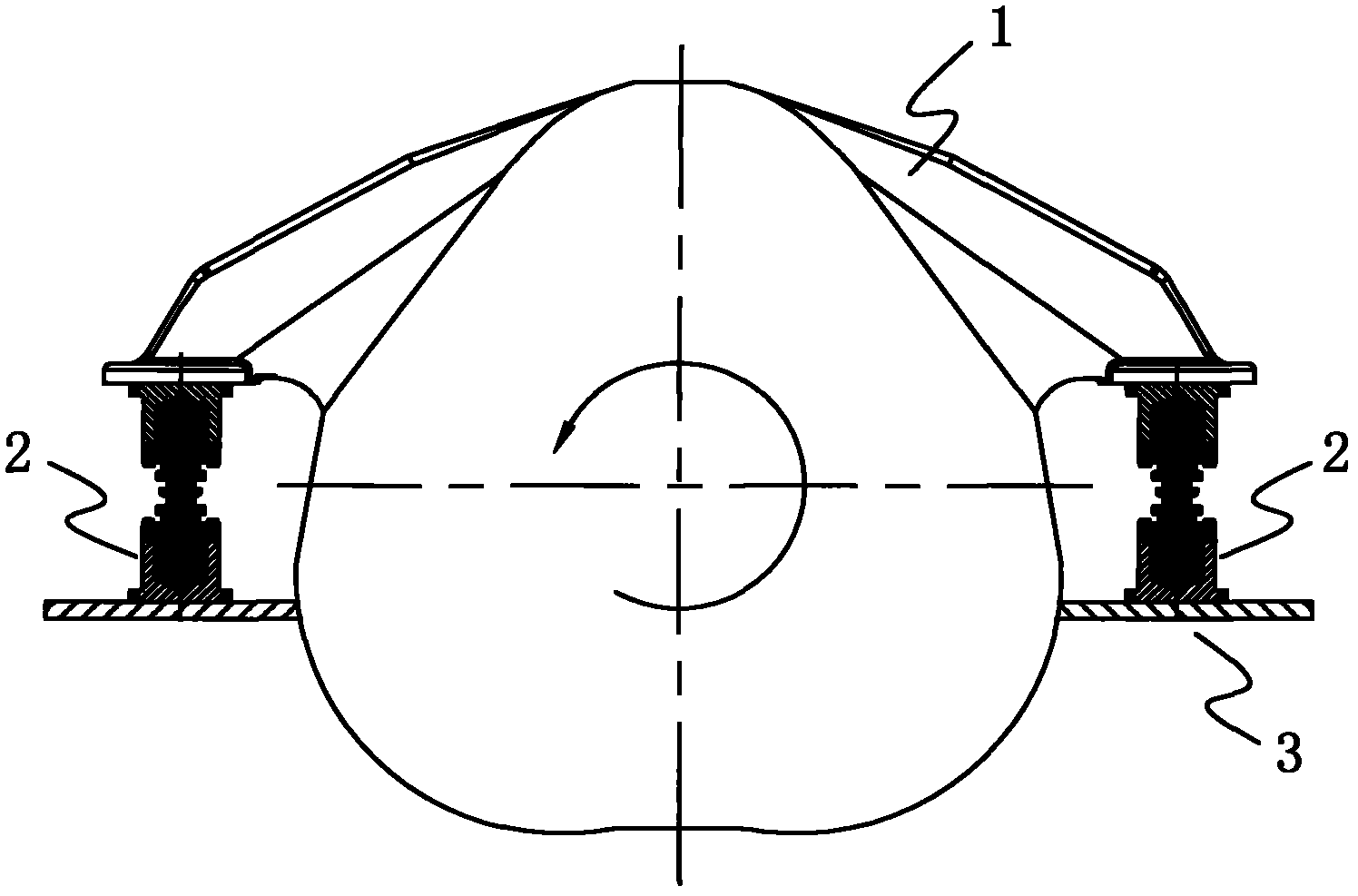

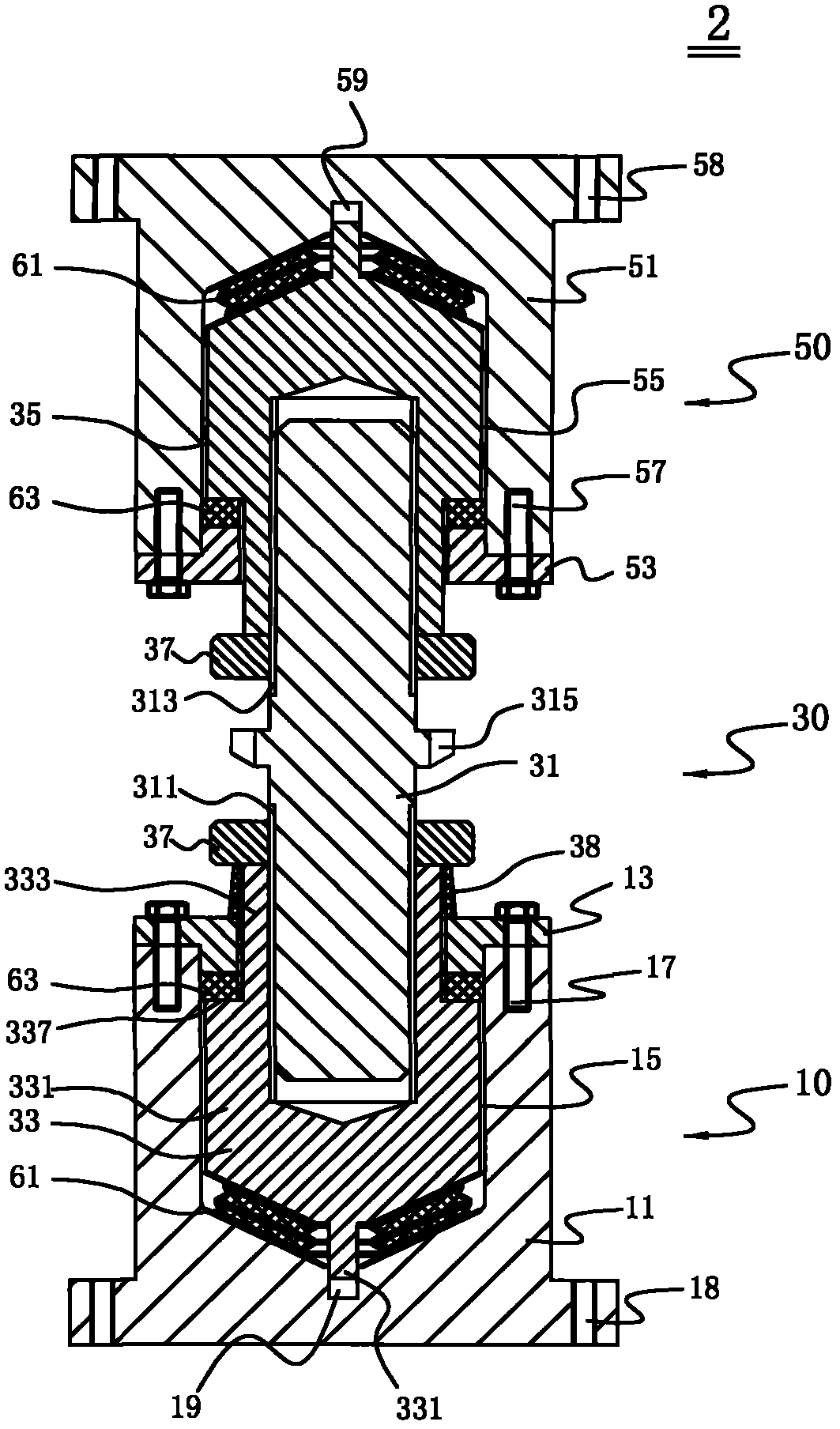

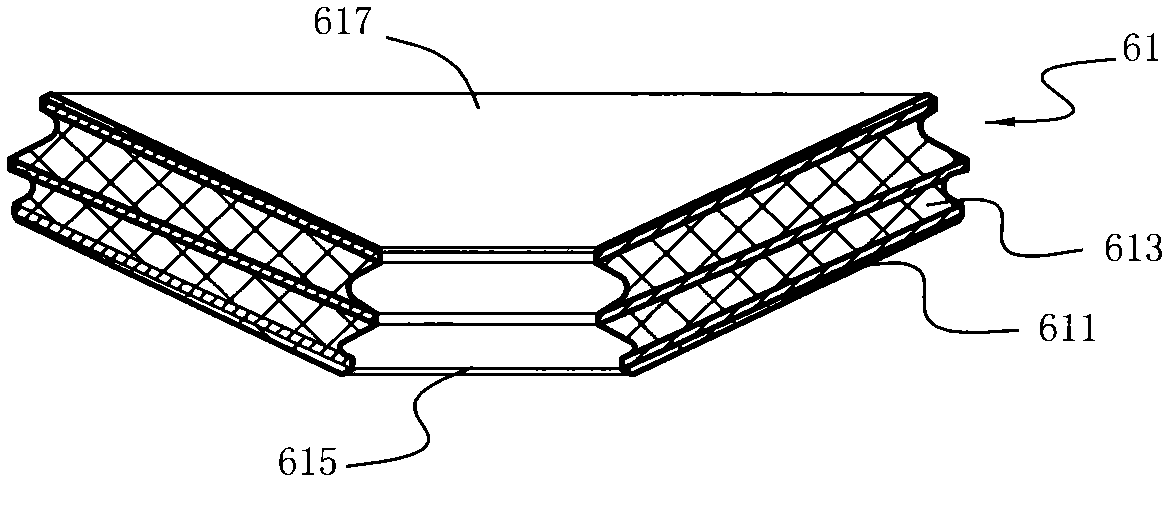

[0029] see Figure 2 to Figure 4 As shown, they are respectively a schematic cross-sectional view of the first embodiment of the vibration-damping support device of the present invention; a schematic cross-sectional view of a tapered rubber laminated spring; and a schematic cross-sectional view of an elastic rubber gasket.

[0030] The vibration-damping support device 2 of the first embodiment of the present invention includes: a mounting base 10 , a height adjusting device 30 and a connecting base 50 .

[0031] The mounting seat 10 includes a seat body 11 defining a receiving cavity 15 and a propping cover 13 installed at the opening of the containing cavity 15 , the seat body 11 and the propping cover 13 are connected by bolts 17 . The bottom of the accommodating chamber 15 is conical, and the upward extending portion is cylindrical. A keyway 19 is provided in the middle of the bottom of the accommodating chamber 15 . A mounting hole 18 is provided at the outer bottom of th...

no. 2 example

[0042] see Figure 6 Shown is a schematic cross-sectional view of the second embodiment of the vibration-damping support device of the present invention.

[0043] The vibration-damping support device 2 of the second embodiment of the present invention includes: a mounting base 10 and a height adjusting device 40 .

[0044] The mount 10 of this embodiment is the same as that of the first embodiment.

[0045] The height adjusting device 40 of this embodiment includes a first structural member 41 and a height adjusting member 43 connected with the first structural member 41 by a screw pair.

[0046] The main body of the first structural member 41 is a stepped cylindrical structure, including a large diameter part 411 and a small diameter part 413; The conical shape matches; the small diameter part 413 protrudes out of the housing cavity 15 through the middle hole of the top cover 13, and the protruding end is provided with a threaded hole 419 or a stud 419' for connecting the s...

no. 3 example

[0052] see Figure 7 Shown is a schematic cross-sectional view of the third embodiment of the vibration-damping support device of the present invention.

[0053] The vibration-damping support device 2 of the third embodiment of the present invention includes: a mounting base 10 , a height adjusting device 20 and a connecting base 70 .

[0054] The mounting seat 10 includes a seat body 11 defining a receiving cavity 15 and a propping cover 13 installed at the opening of the containing cavity 15 , the seat body 11 and the propping cover 13 are connected by bolts 17 . The accommodating cavity 15 is cylindrical, and a keyway 19 is provided in the middle of the bottom of the accommodating cavity 15 . A mounting hole 18 is provided at the outer bottom of the base body 11 extending outward.

[0055] The connecting base 70 includes a connecting plate 71 and a connecting portion 73 extending downward, the connecting portion 73 is formed with an internal threaded hole 731 , and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com