Wind-speed and wind-direction sensor

A technology of wind speed, wind direction, and sensors, which is applied in the directions of instruments, fluid speed measurement, speed/acceleration/shock measurement, etc. It can solve the problems of easy wear, large volume, and high price, and achieve clear principles, strong anti-interference ability, and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings.

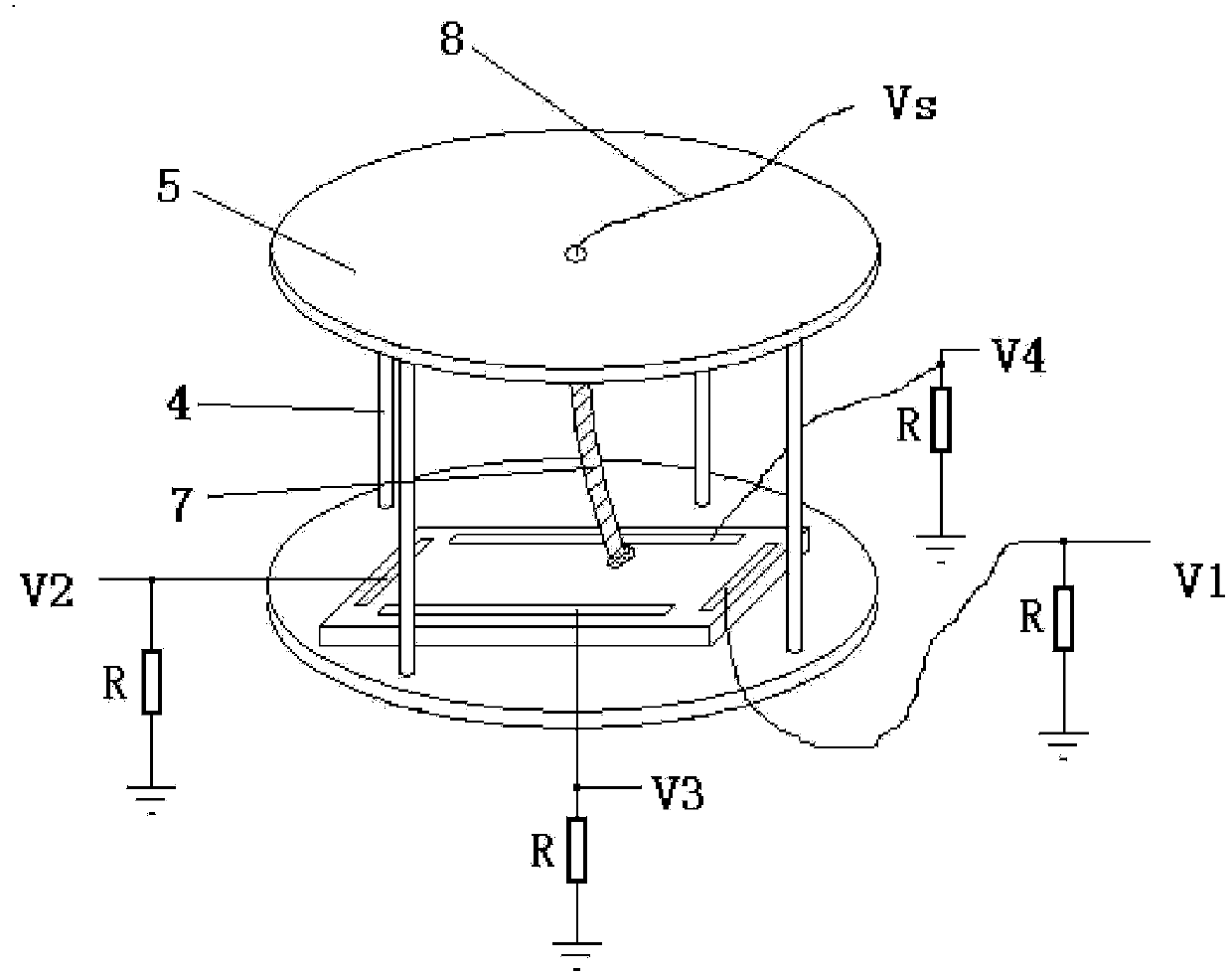

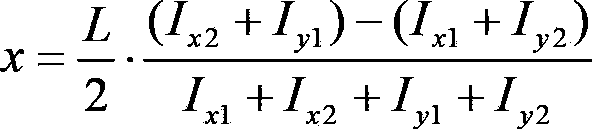

[0015] The small wind speed and wind direction sensor structure proposed by the present invention mainly uses the principle of resistance shunt to realize two-dimensional wind speed and wind direction measurement.

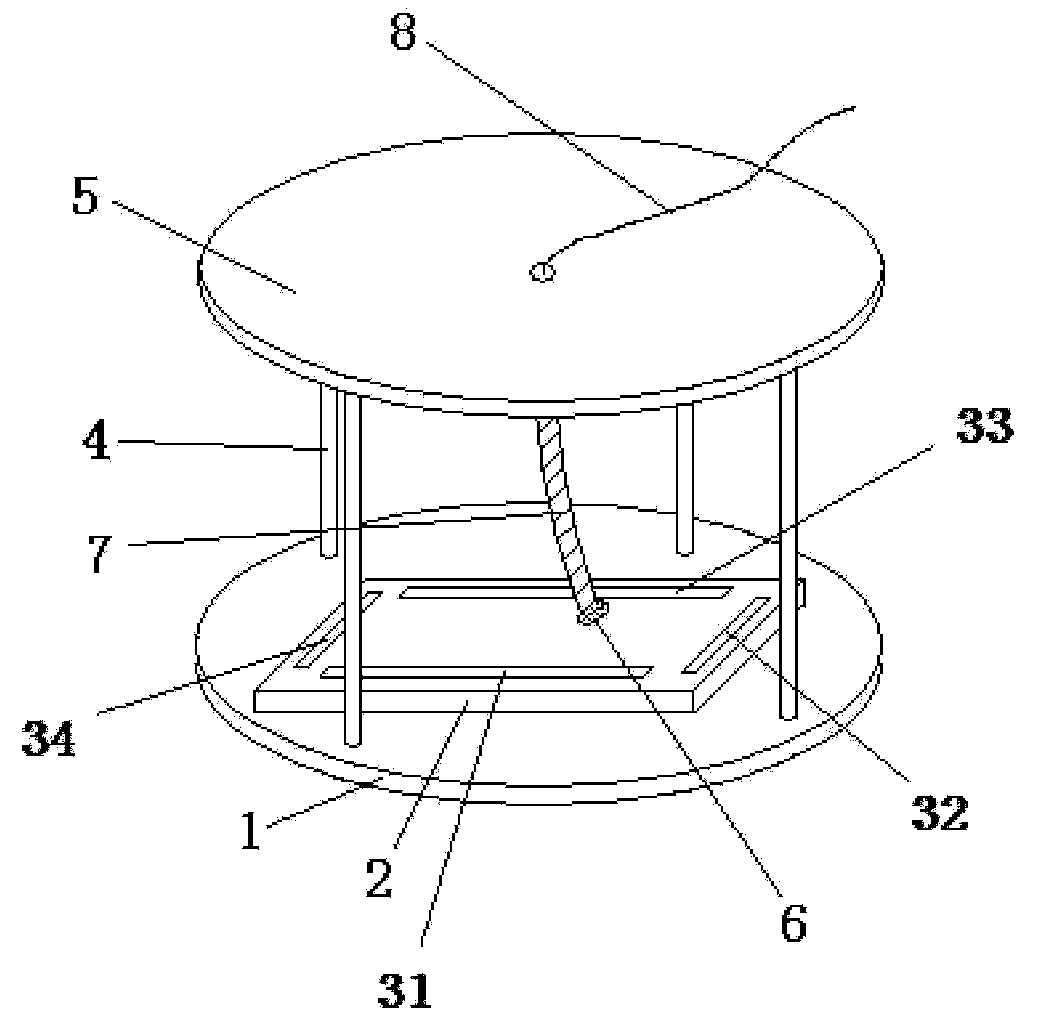

[0016] The structure of the sensor is attached figure 1 As shown, a wind speed and direction sensor includes a base plate 1, a resistive layer 2 arranged on the base plate 1, a first electrode 31, a second electrode 32, and a third electrode 33 respectively arranged on the resistive layer 2 and not connected to each other. And the fourth electrode 34, the top plate 5 arranged opposite to the bottom plate 1 and a certain distance away, the support rod 4 connecting the bottom plate 1 and the top plate 4, the capacitor electrode 6 provided on the top plate 5, and the wind between the bottom plate 1 and the top plate 4 Sensitive rod 7, wire 8 arranged on the top plate 5;

[0017]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com