Shift register cell, gate driving circuit, data driving circuit and display

A shift register and drive control technology, which is applied in the field of gate drive circuits, data drive circuits and shift register units, can solve the problems of reducing circuit operating speed, slow circuit operating speed, and degradation of transistor device characteristics, so as to reduce design Effects of complexity, increased operating speed, and reduced rise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

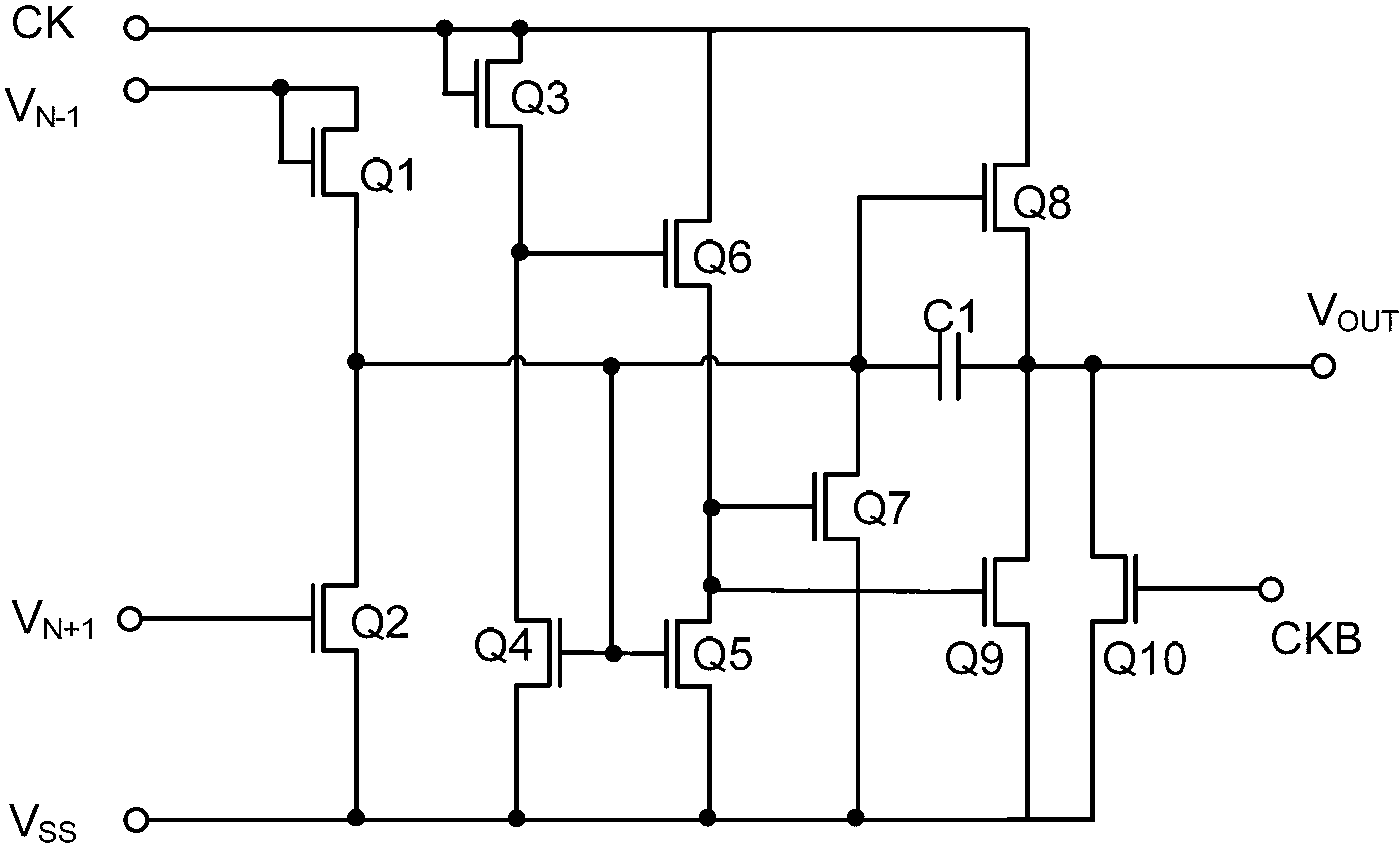

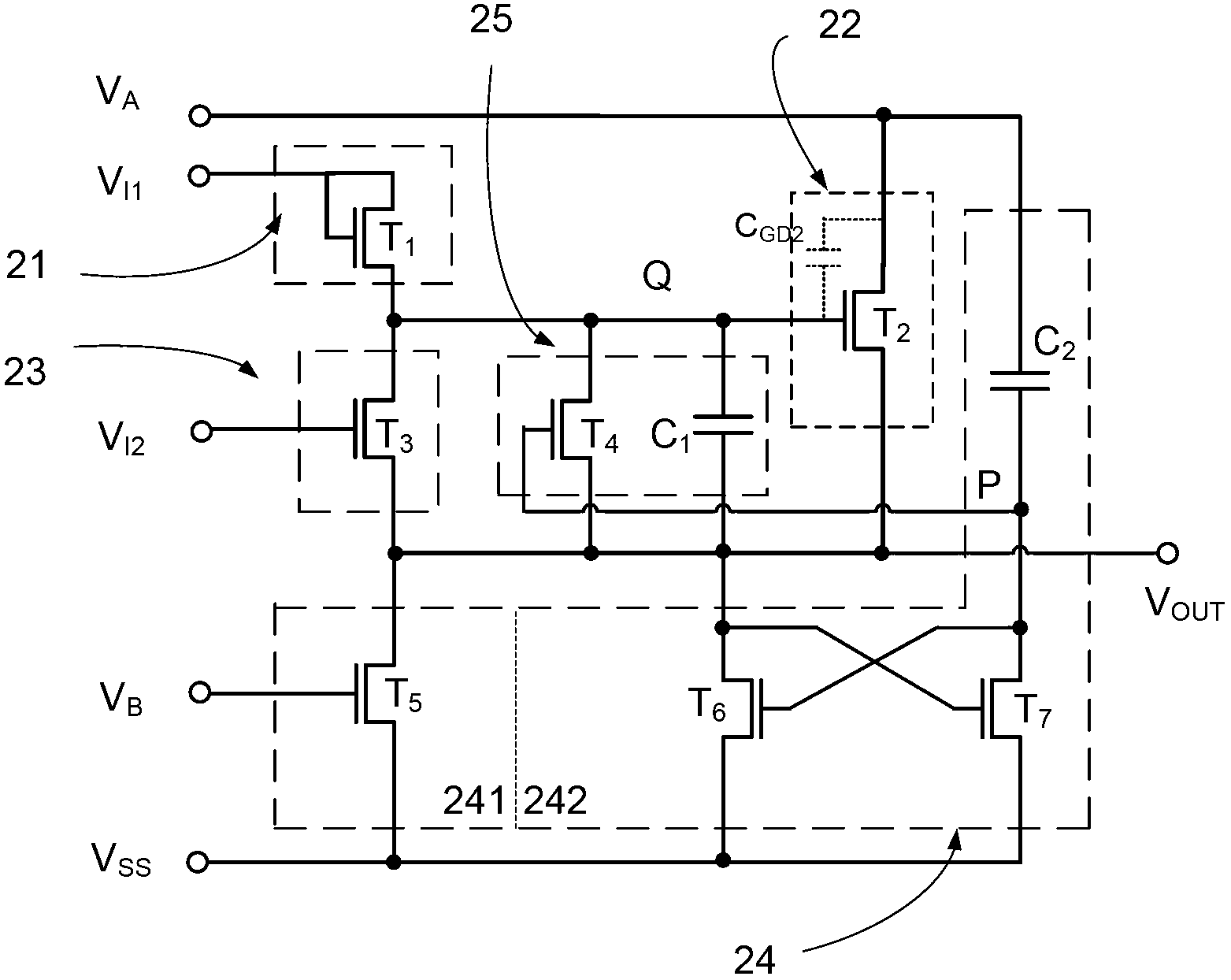

[0055] The shift register unit is a very important unit circuit to realize the gate drive circuit and the data drive circuit. Take the shift register unit as an example, such as image 3 As shown, the shift register unit of this embodiment includes an input module 21 , a driver module 22 , a driver control terminal pull-down delay module 23 , a clock feedthrough suppression module 25 and a low level maintenance module 24 .

[0056] The signal input end of the input module 21 is connected to the first signal input end, and the first pulse signal V is input. I1 ; The clock input end of the driving module 22 is connected to the first clock signal input end, and the first clock signal V is input A , the drive module 22 has a drive control terminal Q, the output terminal of the input module 21 is connected to the drive control terminal of the drive module 22, and the input module 21 is used to receive the first pulse signal V from the first signal input terminal I1 , to provide a ...

Embodiment 2

[0106] like Figure 9 Shown is a circuit diagram of a second embodiment of a shift register unit. Compared with the first embodiment of the shift register unit, the circuit in this embodiment adopts the same clock feedthrough control module 25, including a small-sized fourteenth transistor T 14 and the eleventh capacitor C 11 , but the fourteenth transistor T 14 Using a conventional connection: the fourteenth transistor T 14 The control pole of is coupled to the first signal input terminal, and its first pole (such as the drain) and second pole (such as the source) are respectively coupled to the drive control terminal Q and the signal output terminal V OUT ; Eleventh capacitor C 11 Coupled to the drive control terminal Q and the signal output terminal V OUT between. In the non-selection stage of the shift register unit, when the first clock signal V A When the level is high, the fourteenth transistor T 14 Turn on and release the coupling charge of the driving control ...

Embodiment 3

[0111] like Figure 10 Shown is a circuit diagram of the shift register unit of the third embodiment. Compared with Embodiment 1 or 2 of the shift register unit, a pull-down unit 26 is added in the circuit of this embodiment, including a transistor T 8 . Transistor T 8 The control pole of is connected to the second signal input terminal and responds to the second pulse signal V B , whose first pole (such as drain) and second pole (such as source) are respectively coupled to the signal output terminal V OUT with a low potential source V SS . In this embodiment, the working process of the shift register unit is basically the same as that of Embodiment 1 of the shift register unit, and will not be repeated here. The difference is that during the pull-down process of the shift register unit, the eighth transistor T 8 conduction, the signal output terminal V OUT can also be turned on by the transistor T 8 Discharge; therefore, the falling time of the output signal can be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com