Stator-free brushless dual-rotor outer ring permanent magnet synchronous motor with rotating controller

A synchronous motor, permanent magnet technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of large size, increased probability of wear failure, complex control mechanism, etc., and achieve small size, reduced size, and manufacturing complexity. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

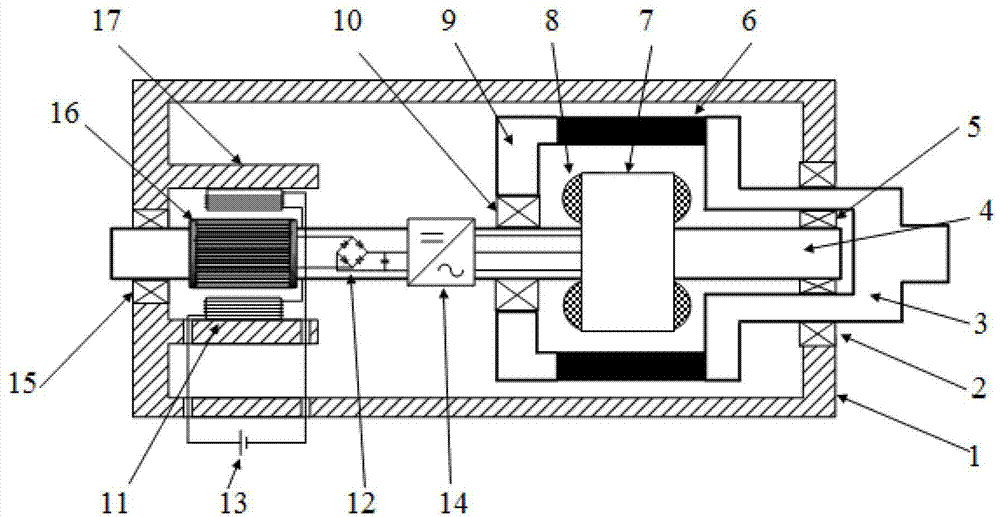

[0030] Such as figure 1 As shown, this embodiment includes: a casing 1, an outer rotor and an inner rotor, the outer rotor includes an outer shaft 3, the inner end of the outer shaft 3 is arranged inside the casing 1, and the inner ends of the outer shaft 3 are staggered along the circumferential direction The permanent magnet 6, the inner end of the outer shaft 3 is provided with an end cover 9, the outer end of the outer shaft 3 protrudes outside the first end of the casing 1; the inner rotor includes an inner shaft 4, and the inner end of the inner shaft 4 is provided with an outer Inside the rotor, an inner rotor core 7 and an inner rotor winding 8 embedded in the inner rotor core 7 are provided on the inner end of the inner shaft 4 corresponding to the permanent magnet 6, and the outer end of the inner shaft 4 is arranged outside the outer rotor. The outer end of the rotating shaft 4 protrudes outside the second end opposite to the first end of the casing; the outer end o...

Embodiment 2

[0048] Embodiment 2 is a modification example of Embodiment 1.

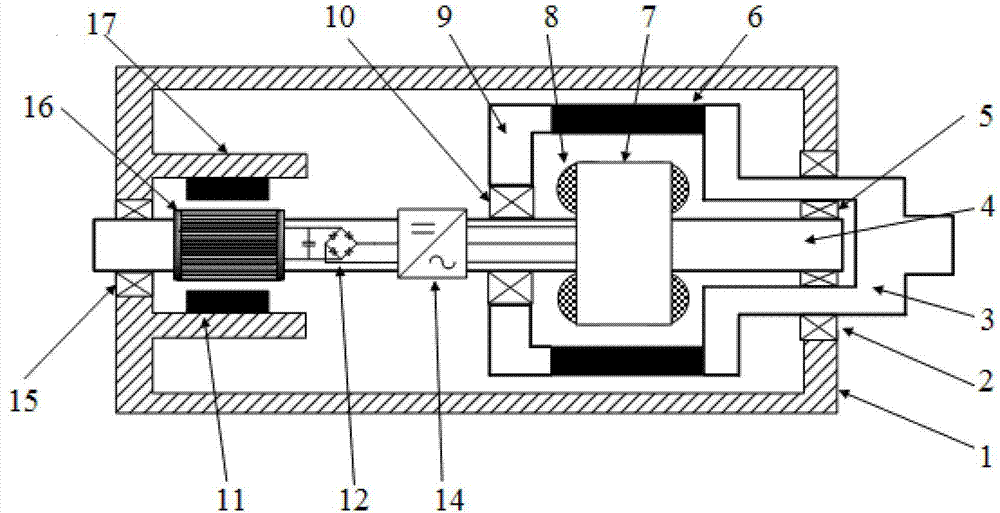

[0049] Such as figure 2 As shown, this embodiment is based on the solution of embodiment 1, and its difference from embodiment 1 is that the inductor structure includes an inductor housing 17 arranged in the second end of the casing and an inductor housing 17 arranged in the inductor housing. The induction permanent magnet 11 and the squirrel-cage aluminum strip structure 16, wherein:

[0050] -The induction permanent magnet 11 is fixed on the inductor housing 17, and the direction of the magnetic field generated is just opposite, and is vertical to the outer end of the inner rotating shaft in space;

[0051] - The squirrel-cage aluminum bar structure 16, whose upper and lower parts have the same direction of the induced magnetic force, is fixed on the outer end of the inner rotating shaft 4 and rotates with the outer end of the inner rotating shaft 4, continuously cutting the induction permanent magnet 11 to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com