Power module and current converter

A power module and power unit technology, applied in the field of electronics, can solve the problems of high height, large height and volume, and high converter height, and achieve the effect of avoiding large overall volume, small height and volume, and improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

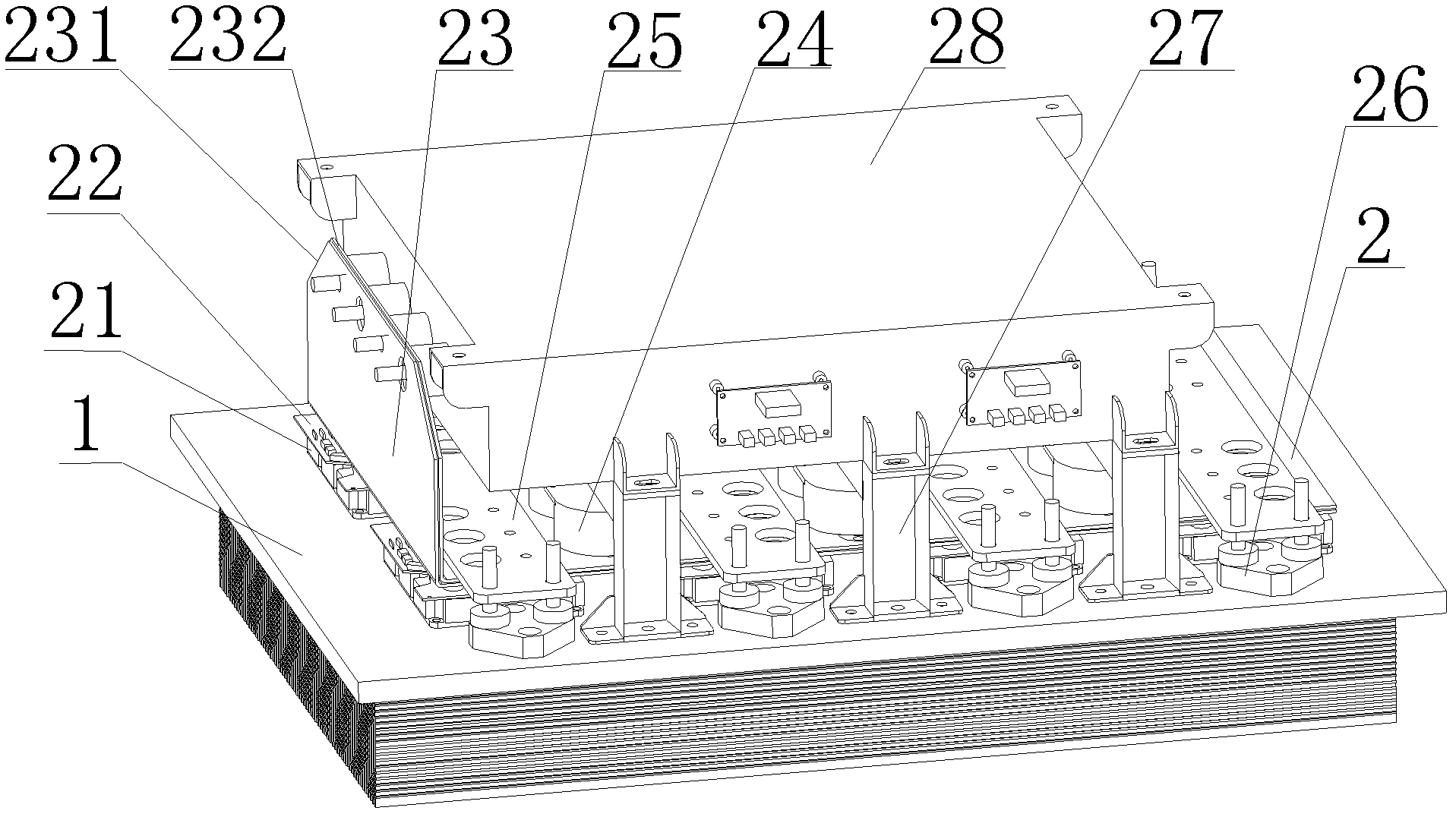

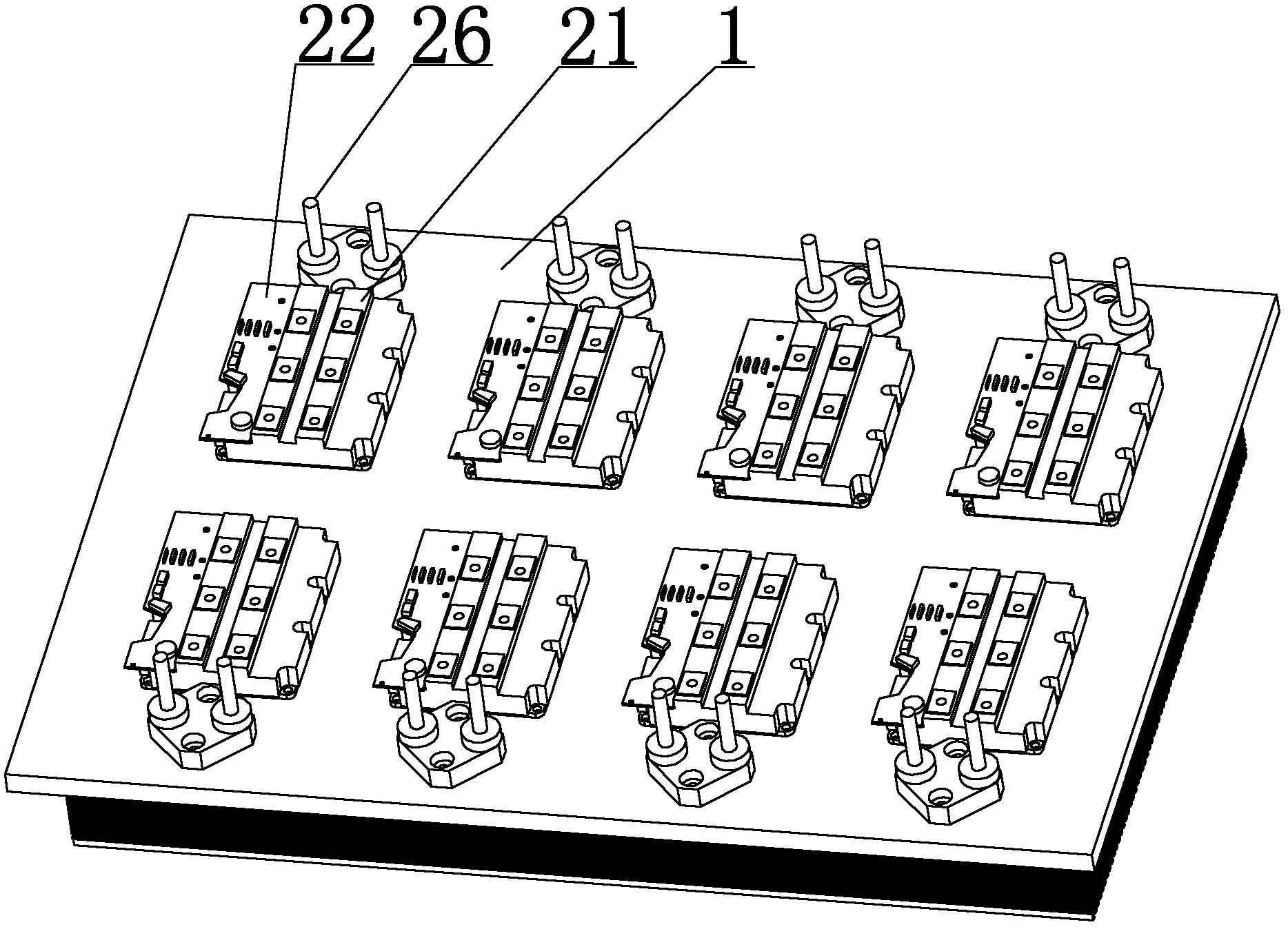

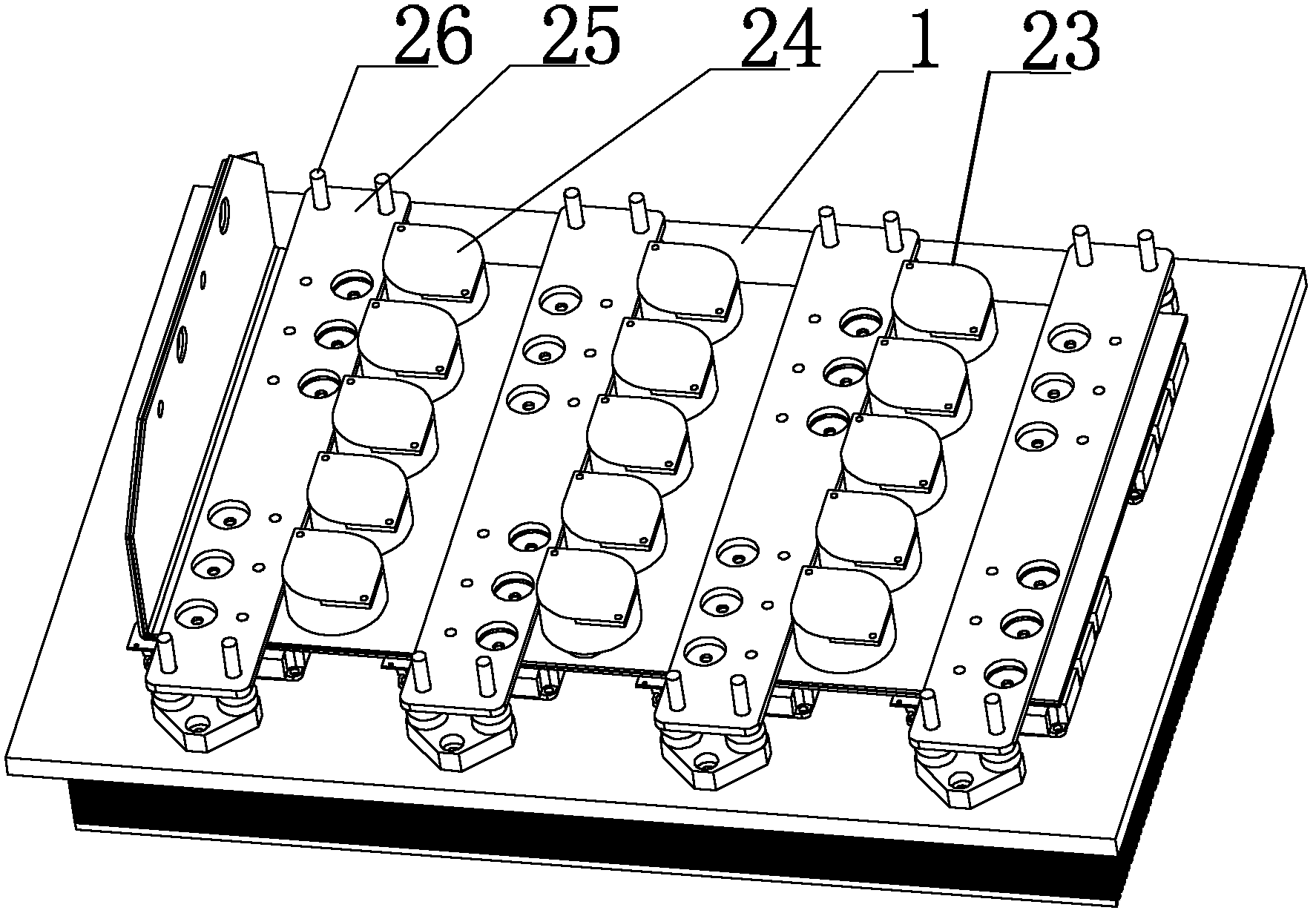

[0028] figure 1 A schematic structural diagram of a power module provided by an embodiment of the present invention. Such as figure 1 As shown, the power module of this embodiment includes a flat radiator 1, on which there are multiple groups of power units 2, and each power unit 2 includes an IGBT 21, a drive circuit board 22, a composite busbar 23, a surge Capacitor 24 and AC outlet copper bar 25. Among them, the IGBT 21 is directly installed on the surface of the flat radiator 1, the driving circuit board 22 is installed on the IGBT 21, and is electrically connected with the IGBT 21; the composite busbar 23 is installed on the IGBT 21 and the driving circuit board 22, and the composite busbar 23 includes a DC positive copper bar 231 and a DC negative copper bar 232. The DC negative copper bar 232 and the DC positive copper bar 231 are electrically connected to the IGBT 21 respectively; The DC negative copper bar 231 and the DC positive copper bar 232 are electrically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com