Screw applied to thighbone posterior condyle fractures

A femur and screw technology, applied in the field of medical fracture fixation devices, can solve the problems of unquantifiable fracture fragment pressure, bone and thread interface damage, screw plastic deformation, etc., and achieve the effects of easily related medical skills, prevention of failure, and assistance in reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

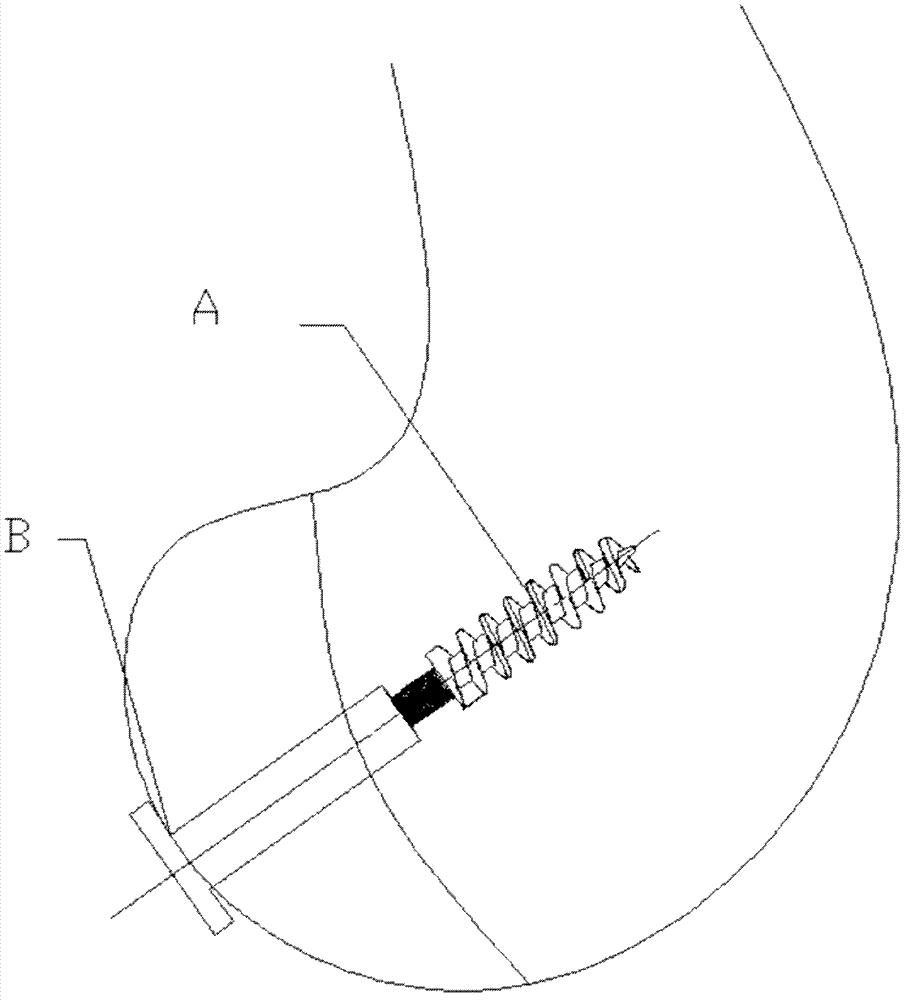

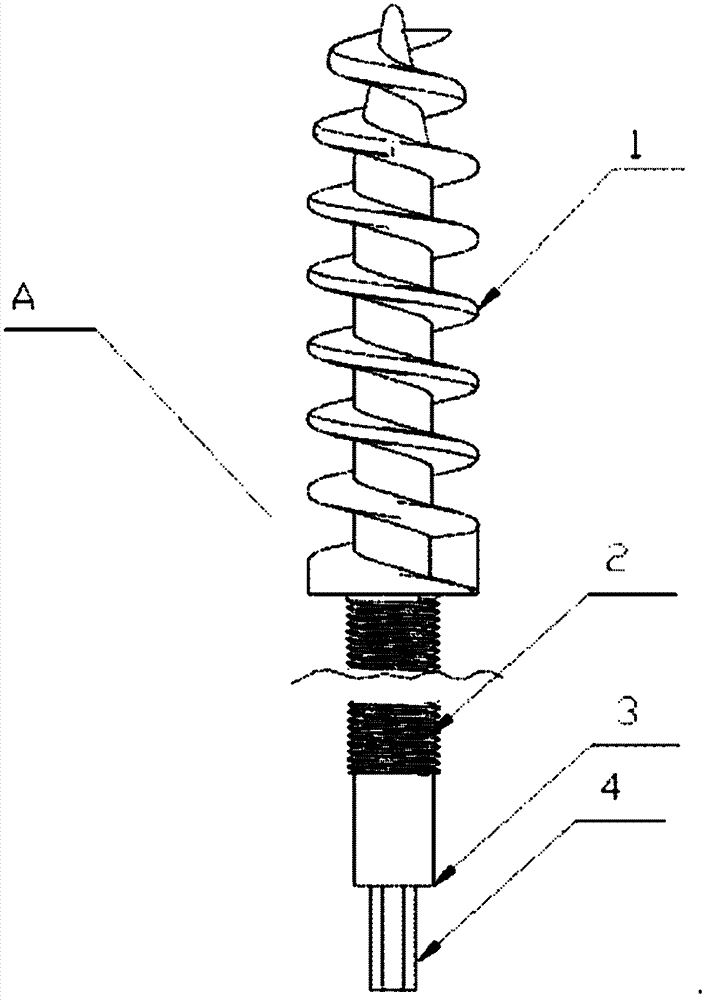

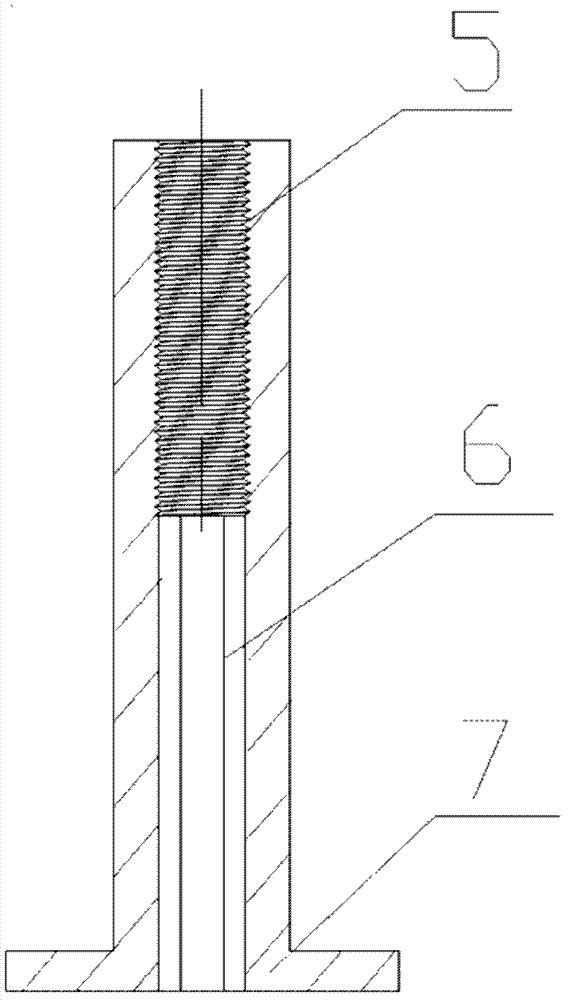

[0014] Such as figure 1 , figure 2 , image 3 , the compression combination screw with quantifiable torsion applied to the fracture of the posterior femoral condyle of the present invention is divided into two parts: component A and component B. Wherein component A is composed of thread 1, thread 2, stem part 3 and tail part 4, and component B is composed of thread 5, prismatic hole 6 and flat end 7.

[0015] Thread 1 of component A is similar or equivalent to the thread design of cancellous bone screws, and its thread depth and pitch are larger than those of thread 2. When in use, thread 1 is screwed into the contralateral posterior femoral condyle fragment. At this time, component A is anchored to the contralateral posterior femoral condyle fragment, and its effect is similar to that of cancellous bone lag screws anchoring in the contralateral posterior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com