Fracture of tibial plateau internal fixing device

A fixation device, tibial plateau technology, applied in the direction of internal fixator, fixator, internal bone synthesis, etc., can solve the problems of inability to quantify fracture fragment pressure, screw plastic deformation, inability to quantify torque, etc., to prevent initial fixation failure, increase The effect of pressure strength, fixed protection and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

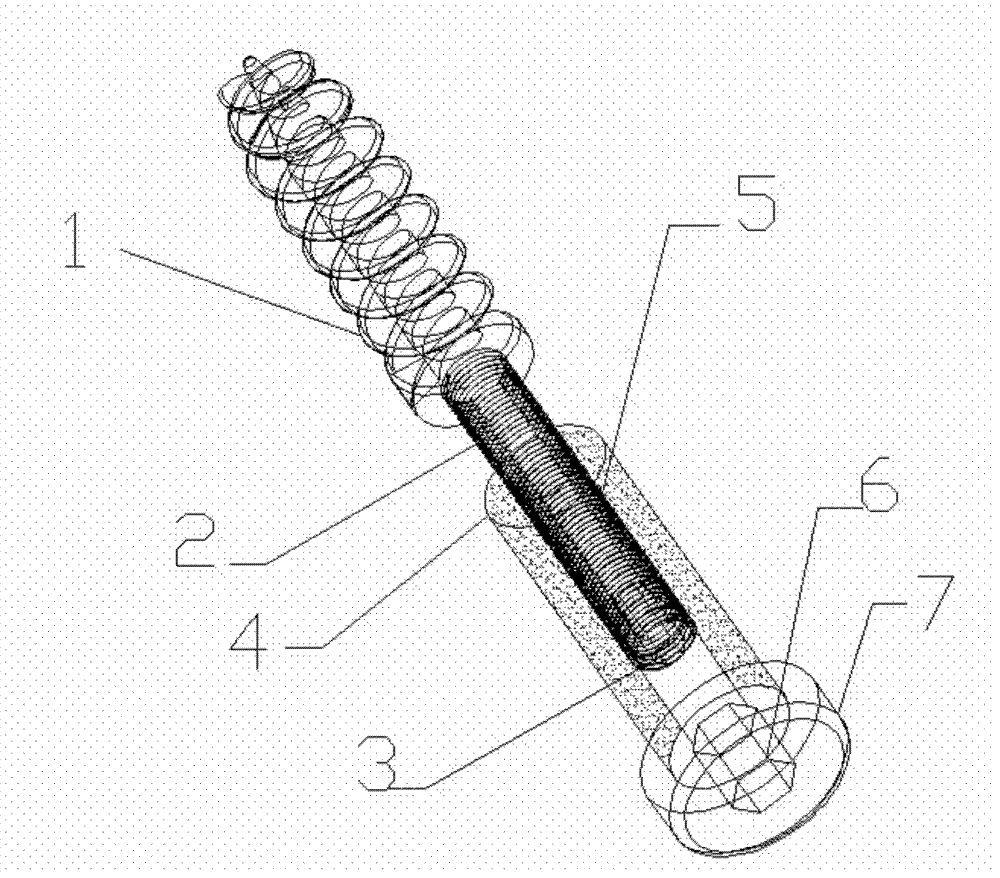

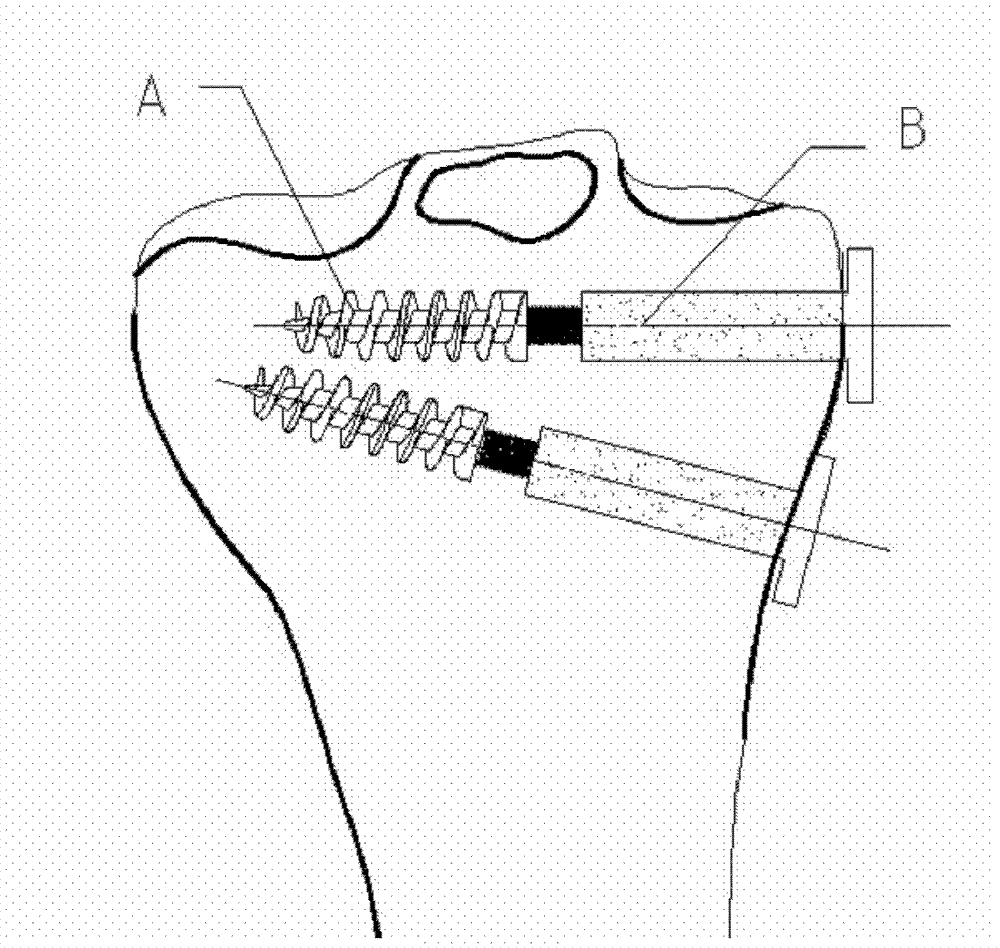

[0014] like figure 1 , figure 2 The internal fixation device for tibial plateau fractures described in the present invention is divided into two parts: component A and component B. Component A consists of thread 1 and thread 2, and the tail is a hollow prism structure, such as a hexagonal prism or other shapes, located in the core of thread 2. One end of the component B is provided with a thread 5 to match the thread 2 of the component A. The thread 5 is a part for realizing the compression effect between the fracture fragments. The other end of the component B is provided with a terminal 7, which contains a prismatic hole 6, and the prismatic hole 6 is connected to the The thread 5 communicates through the transition portion 3 . The surface of component B is treated with sandblasting, porous and hydroxyapatite coating to form a microporous layer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com