Wet-type flue gas dust removal device

A wet dust removal and flue gas technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of limited contact area between flue gas and water, poor dust removal effect, and poor dust reduction effect. Simple structure, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

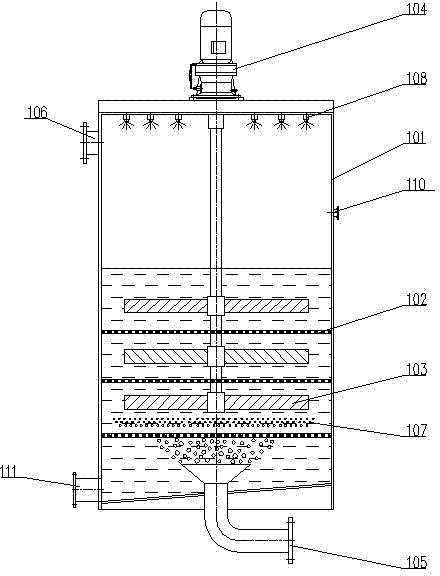

[0013] figure 1 Shown is the flue gas wet dust removal device of the present invention, including a cylinder 101 . The flue gas inlet pipe 105 is arranged at the bottom of the cylinder body, and the gas outlet pipe 106 is arranged at the upper part of the cylinder body. The water inlet 110 is arranged on the upper part of the cylinder side wall, and the sewage outlet 111 is arranged on the lower part of the cylinder side wall. Three layers of screens 102 are arranged horizontally in the lower half of the cylinder body. The stirring shaft of the agitator 104 is vertically arranged in the cylindrical body, and the motor of the agitator is arranged on the top of the cylindrical body. The stirring shaft is provided with three stirring paddles 103, and one stirring paddle is arranged on the top of each layer of screen. Such as figure 1 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com