Heart-shaped roll defect treatment method for cold-rolled steel roll

A technology of cold-rolled steel and coil core, which is applied in the field of cold-rolled steel coil defect control, and can solve the problems that cannot be cured completely, and the range of coil tension optimization cannot be too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

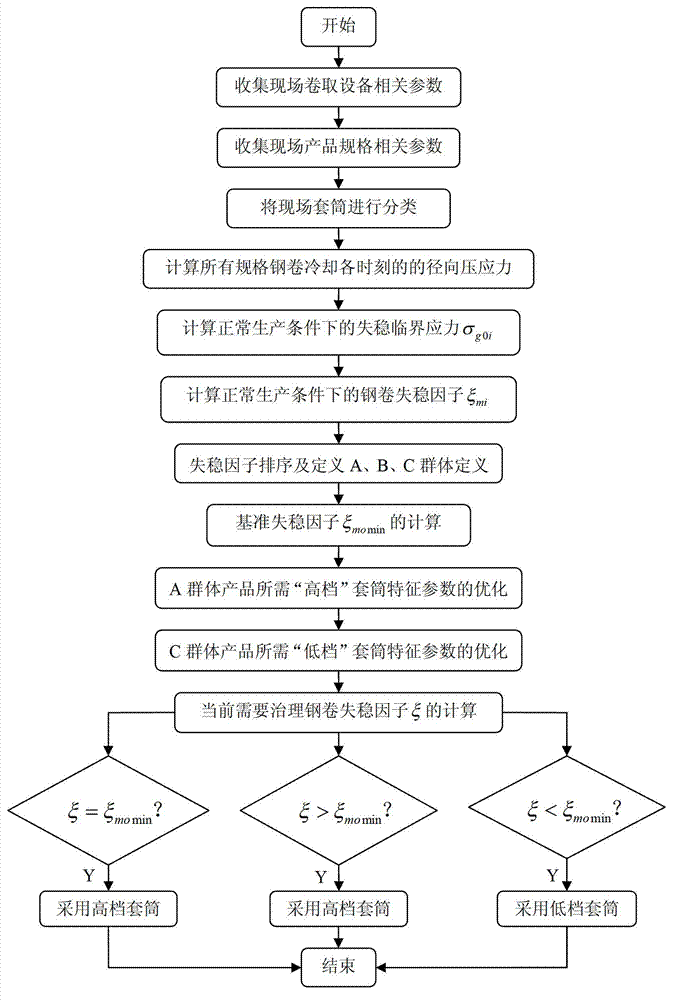

[0042] Such as figure 1 As shown, firstly, in step 1, relevant parameters of on-site coiling equipment are collected, the number of on-site sleeves is 1000, and the outer diameter r of the 1000 sleeves is collected bi , sleeve wall thickness t i , Sleeve material yield limit σ si , i=1,2,...,1000;

[0043] Subsequently, in step 2, relevant parameters of on-site product specifications are collected. There are 100 types of products with different specifications in the on-site product outline, and the specification range and process parameters of the 100 types of products with different specifications are collected, mainly including: strip steel thickness h i , strip width B i , strip elastic modulus E, strip Poisson's ratio v, i=1,2,...,100;

[0044] Subsequently, in step 3, considering the sleeve wall thickness and the yield limit of the sleeve material, the 1000 sleeves on site were divided into three grades of "high", "medium" and "low";

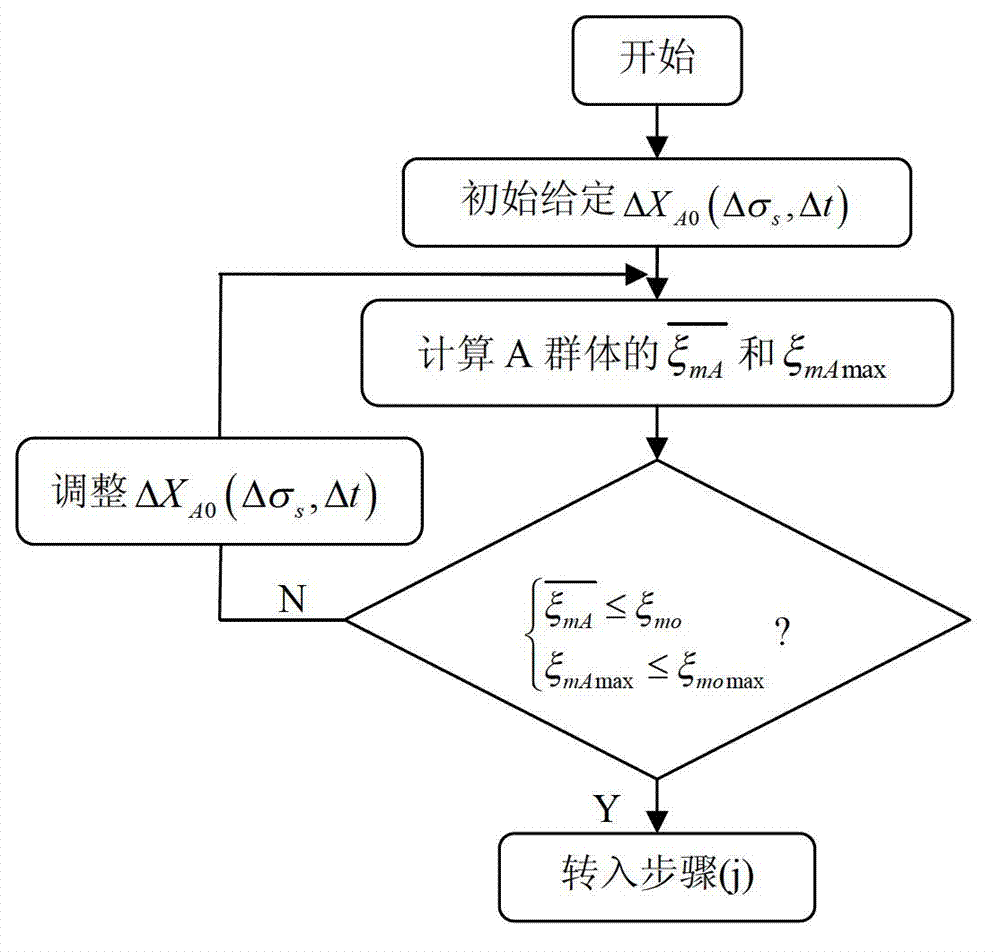

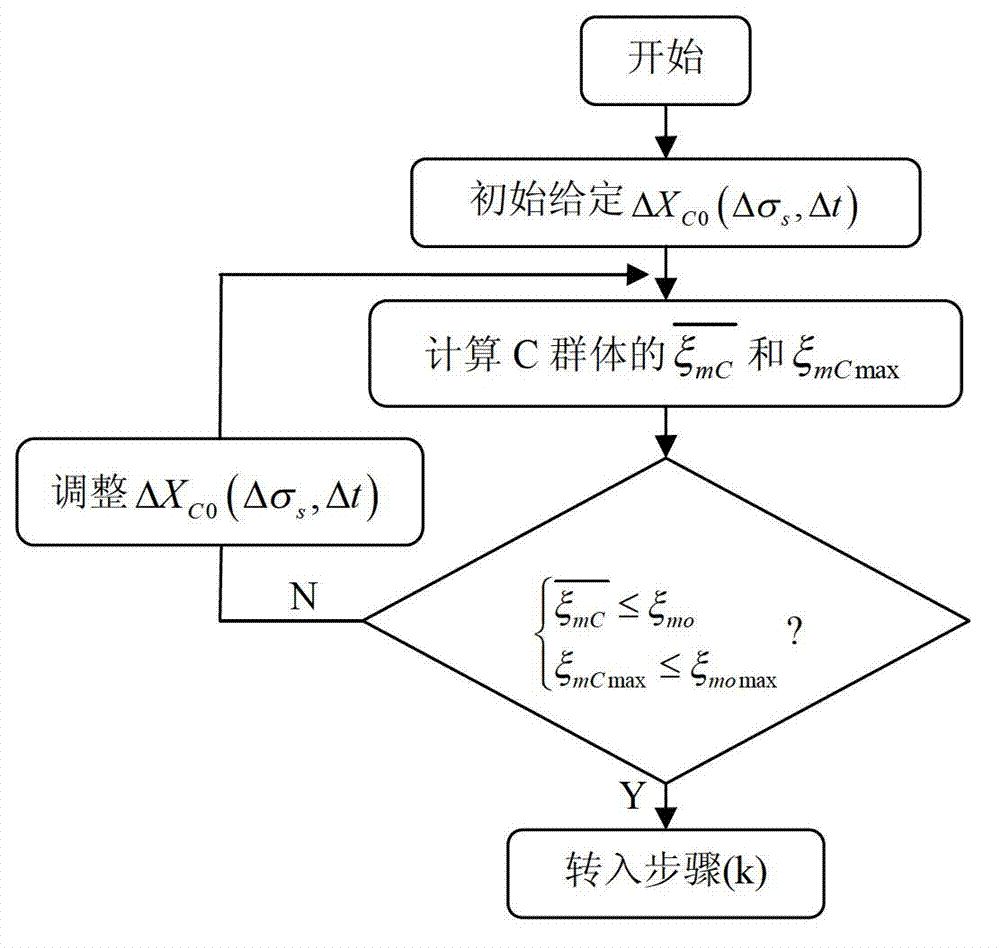

[0045] Then, in step 4, calcula...

Embodiment 2

[0060] First, in step 1, collect the relevant parameters of the on-site coiling equipment. The number of on-site sleeves is 2000, and the outer diameter r of the 2000 sleeves is collected bi , sleeve wall thickness t i , Sleeve material yield limit σ si , i=1,2,...,2000;

[0061] Subsequently, in step 2, relevant parameters of on-site product specifications are collected. There are 200 types of products with different specifications in the on-site product outline, and the specification range and process parameters of the 200 types of products with different specifications are collected, mainly including: strip steel thickness h i , strip width B i , strip elastic modulus E, strip Poisson's ratio v, i=1,2,...,200;

[0062] Subsequently, in step 3, considering the sleeve wall thickness and the yield limit of the sleeve material, the 2000 sleeves on site were divided into three grades of "high", "medium" and "low";

[0063] Then, in step 4, calculate the radial pressure betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com