Raw material splicing device

A splicing device and raw material technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problems of not giving full play to the efficiency of machine tools, and achieve the effect of reducing the cost of finger joints or splicing and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

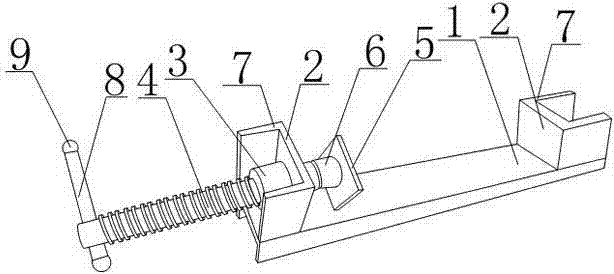

[0019] Such as figure 1 Therefore, a raw material splicing device according to the present invention includes a flat plank 1, and baffles 2 are arranged at both ends of the plank 1, and the baffles 2 are located on the upper surface of the plank 1 and are perpendicular to the plank 1, and at the top of the plank 1 Both the bottom and the outer sides of the two baffles are provided with reinforcing strips 7; one of the baffles 2 is provided with a threaded sleeve 3 that penetrates the baffle 2, and the axis of the threaded sleeve 3 is parallel to the axial direction of the plank 1. A screw 4 matching the threaded sleeve 3 is installed in the threaded sleeve 1, and the end of the screw 4 between the two baffles 2 is cylindrical, and an orientation sleeve 6 is set on the cylinder. The cylinder 6 is fixedly connected on the top plate 5, and a through hole is arranged at the other end of the screw rod 4, a torsion arm 8 is installed in the through hole, and a stop ball 9 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com