Bonding-resistant tool based on lotus leaf surface bionics and preparation method thereof

A bionic and anti-adhesive technology, applied in chemical instruments and methods, lamination devices, lamination, etc., can solve the problems of complexity and difficulty in optimizing the types of coating materials, to improve quality, reduce roughness, reduce The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

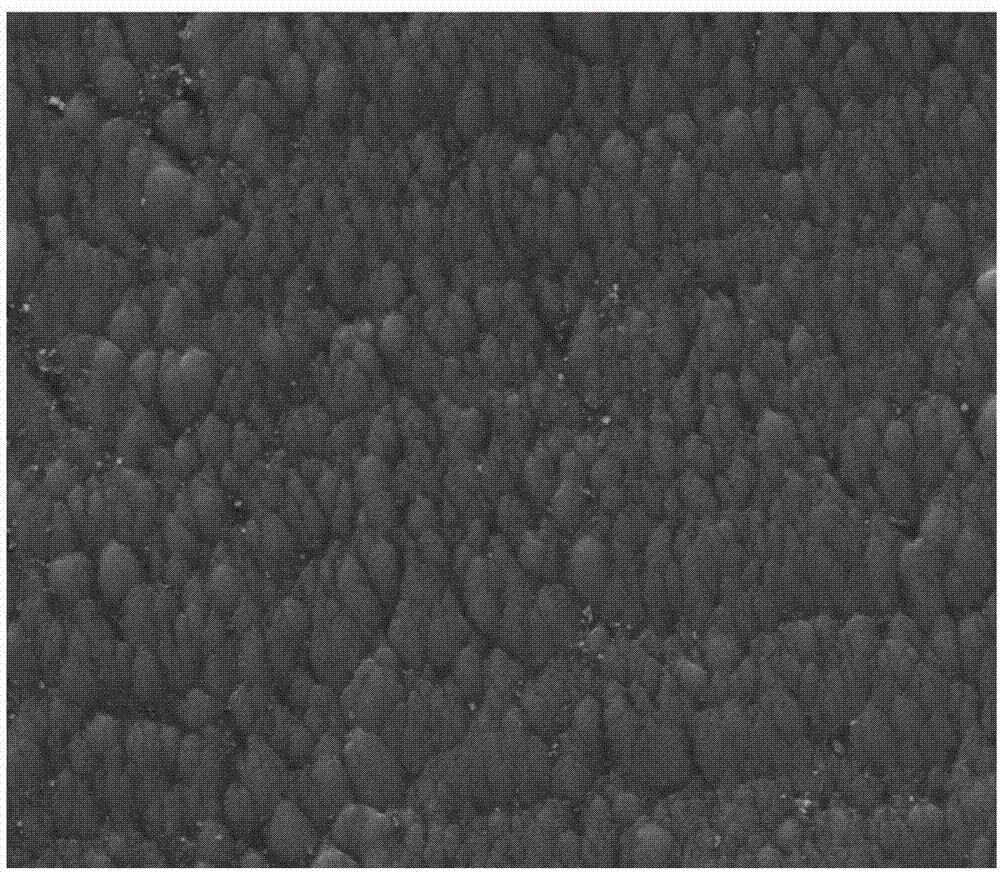

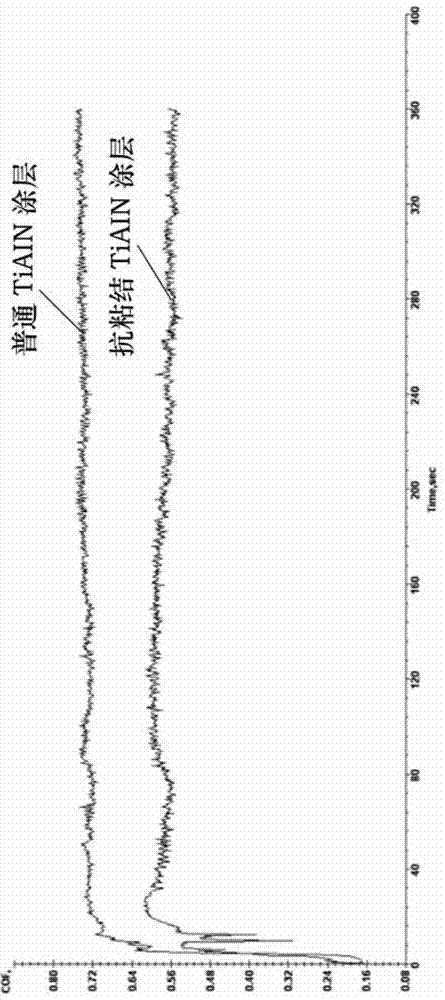

[0025] see figure 1 and figure 2 As shown, the embodiments of the present invention will be described in detail.

[0026] The invention relates to a bionics-based anti-bonding cutter, which comprises a cutter substrate, the cutter substrate is covered with a transition layer, nucleation particles are introduced on the transition layer, and a coating is coated on the nucleation particles , and the nucleation particles are combined with the coating covering the surface of the nucleation particles to form asperities.

[0027] The present invention also relates to a preparation method of an anti-bonding cutter based on lotus leaf surface bionics, the preparation method comprising the following steps:

[0028] Step 10, depositing a transition layer on the surface of the ground tool substrate,

[0029] Step 20, using gravity deposition in an organic solvent to introduce nucleation particles onto the transition layer, and then using ultrasonic vibration to evenly spread the nucle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com