Energy recycling and reusing device of hoisting machinery

A technology for energy recovery and hoisting machinery, which is used in transportation and packaging, load hoisting components, etc., can solve the problems of wasting energy and low work efficiency, and achieve the effect of compact device structure, high work efficiency and minimized energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

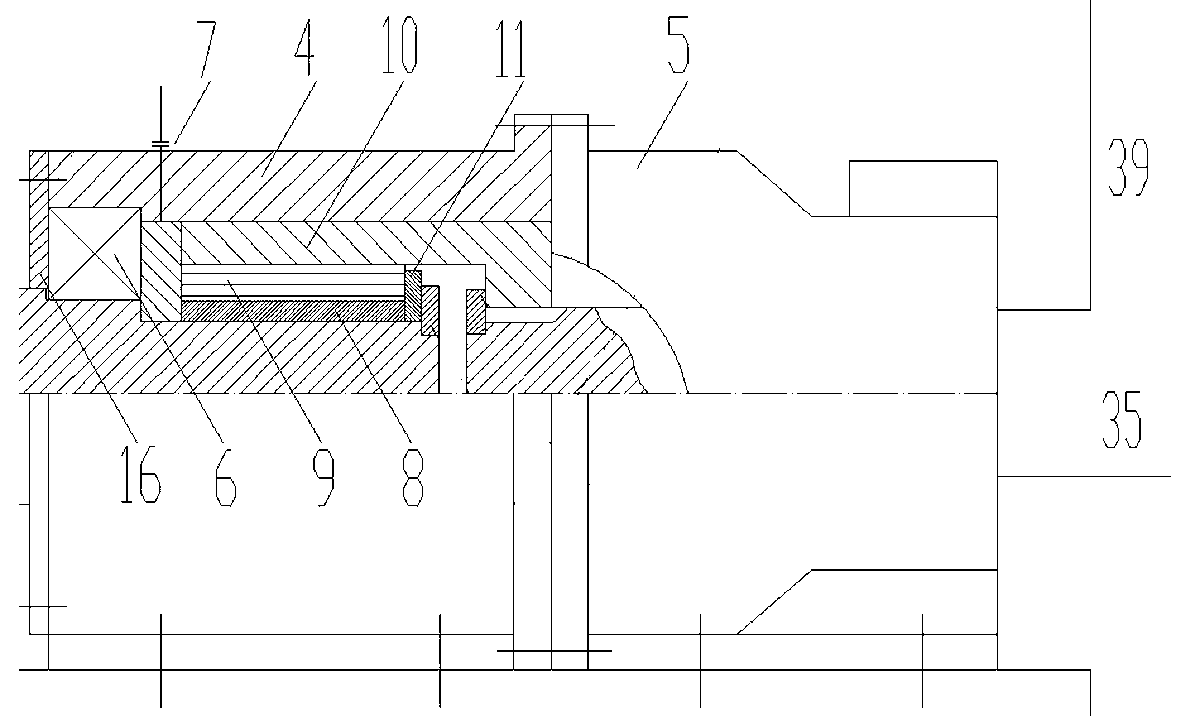

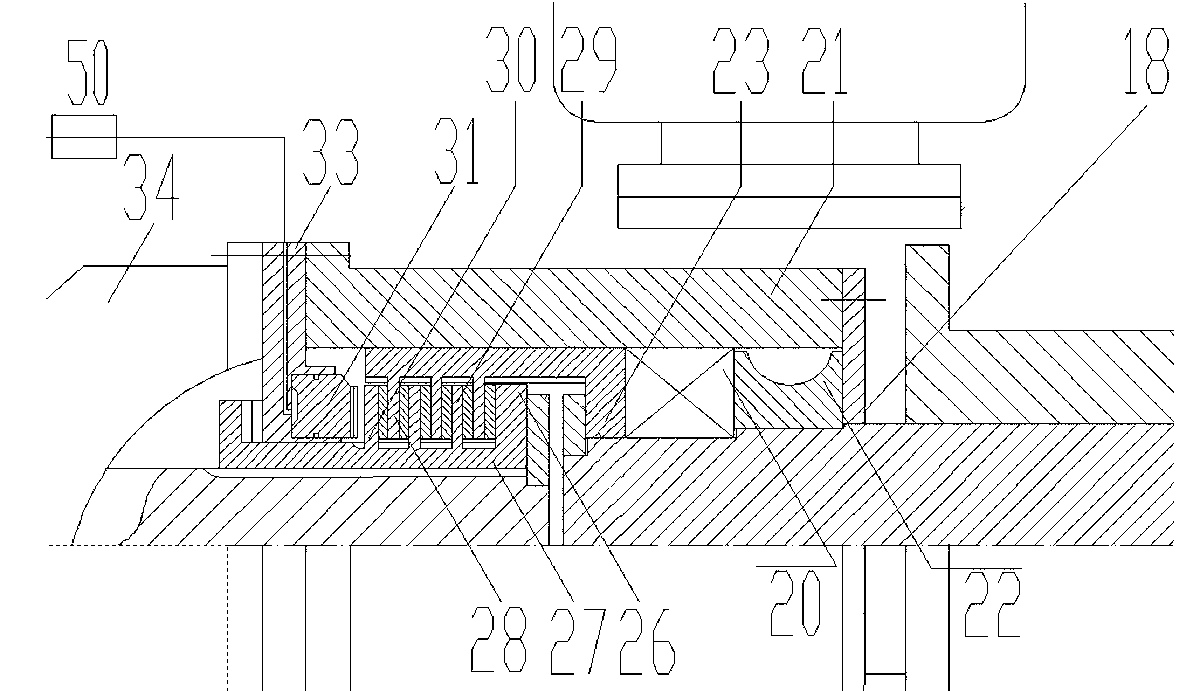

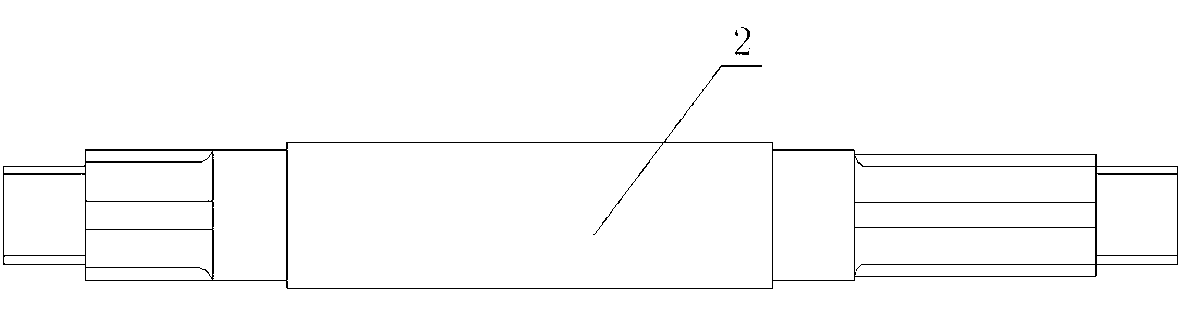

[0017] refer to figure 1 , 2 , 3, 4, the present embodiment comprises overrunning clutch and power clutch, described power clutch top is provided with drive linkage device 21, and overrunning clutch is provided with energy storage coupling device 4, and overrunning clutch and power clutch are provided with main shaft 2 below, main shaft 2 The hydraulic variable pump 5 and the hydraulic variable motor 34 are arranged on both sides, and the hydraulic variable pump 5 and the hydraulic variable motor 34 are fixedly connected with the base plate 1; the energy storage connection device 4 is equipped with a main shaft bearing 6 and a speed signal sensor group 7 , Overrunning clutch active sleeve 8, overrunning clutch needle roller 9, overrunning clutch passive sleeve 10, overrunning clutch needle roller gear 11; overrunning clutch active sleeve 8, overrunning clutch needle ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com