Ultraviolet fluid processor with double-layer cavity wall structure

A technology of ultraviolet rays and processors, which is applied in the direction of light water/sewage treatment, irradiation, etc., can solve the problems of high manufacturing cost of processors, and the lack of pressure resistance of rectangular processors, so as to reduce equipment costs and have little influence on fluid mixing dynamics , Improve the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 is an ultraviolet fluid processor in which the reactor cavity of the technical solution 1 of the present invention is a double-layer cavity wall structure.

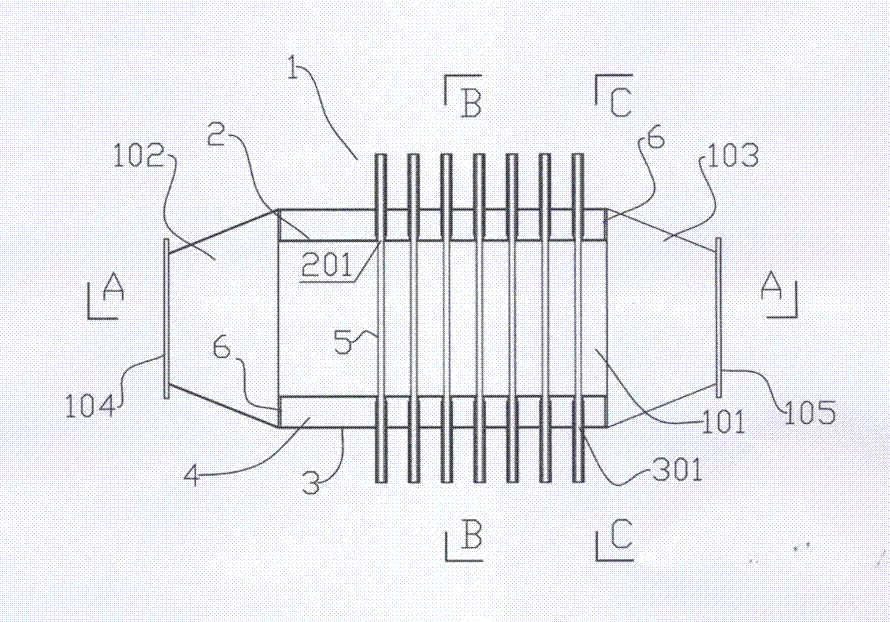

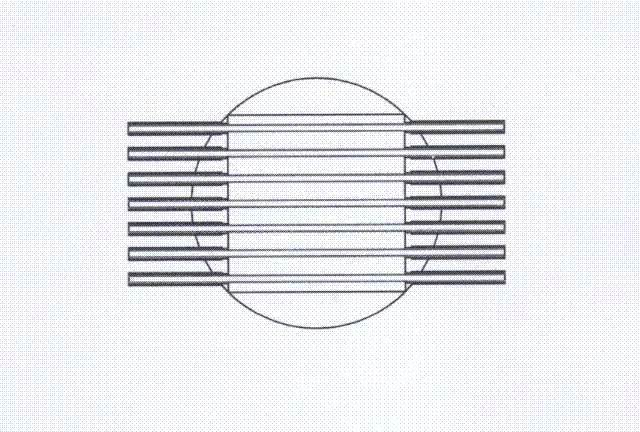

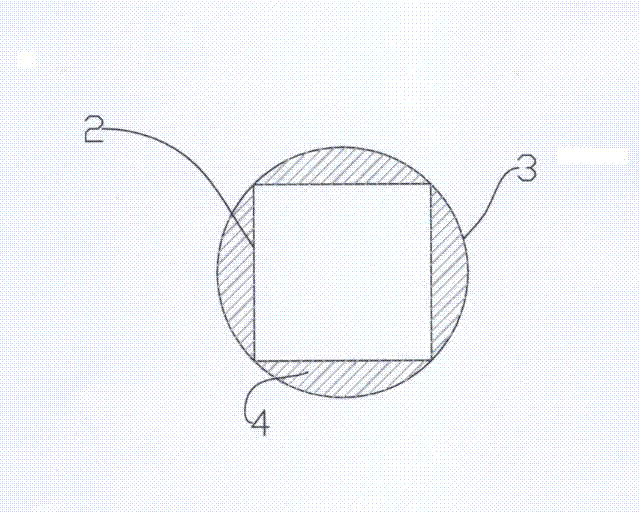

[0048] Such as Figure 1-4The shown reactor cavity is an ultraviolet fluid processor 1 with a double-layer cavity wall structure, including a reactor cavity 101, several ultraviolet lamp tubes and sleeves 5 thereof, two ends 106 of the reactor cavity 101 and 107 is provided with a fluid inlet 102 and a fluid outlet 103, and the outer sides of the fluid inlet 102 and the fluid outlet 103 are respectively provided with connecting devices 104 and 105. The reactor cavity 101 in this embodiment has a double-layer cavity wall structure. The reactor cavity of the double-layer cavity wall structure is composed of the outer cavity wall 3 and the inner cavity wall 2 installed inside the outer cavity wall. The inner cavity wall 2 is a square cross section with two ends open and the Closed circular cylinder. A c...

Embodiment 2

[0054] Embodiment 2 is an ultraviolet fluid processor in which part of the chamber of the reactor chamber of Scheme 2 of the present invention has a double-layer chamber wall structure.

[0055] Such as Figure 5-8 Part of the shown reactor cavity is an ultraviolet fluid processor 1 with a double-layer cavity wall structure, including a reactor cavity 101, several ultraviolet lamps and sleeves 5, and two of the reactor cavity 101 The ends 106 and 107 are provided with a fluid inlet 102 and a fluid outlet 103, and the outer sides of the fluid inlet 102 and the fluid outlet 103 are respectively provided with connecting devices 104 and 105, and part of the cavity of the reactor cavity 101 described in this embodiment is Double wall structure, part of the reactor cavity of the double wall structure is composed of an inner wall 2 and an outer wall 3, and the inner wall 2 is four partitions fixed on the inner side of the outer wall 202, each partition 202 and the outer cavity wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com