Sewage treatment method of vertical current mangrove forest constructed wetland ecosystem

A technology of artificial wetlands and ecosystems, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem of unconstructed mangrove ecosystem and unsuitable natural mangrove wetland sewage Treatment, pollution and purification functions are not fully brought into play, to achieve the effect of increasing the area of microbial adhesion, solving the difficulty of replacement, and increasing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

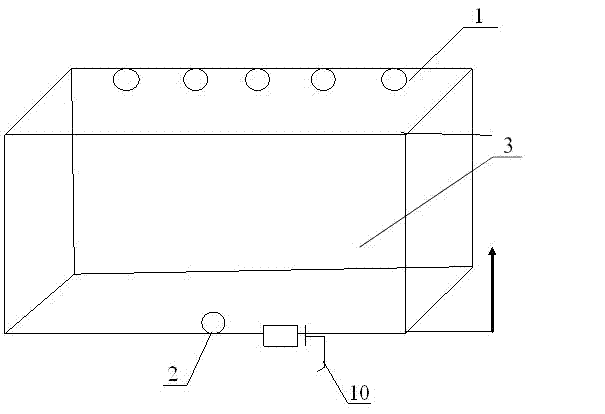

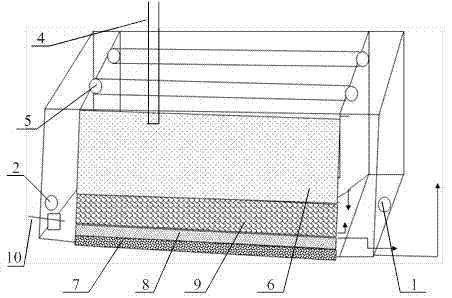

[0031] like figure 1 and figure 2 Shown, a kind of construction method of vertical flow mangrove artificial wetland ecosystem technology, comprises: step A: establish artificial wetland, described artificial wetland comprises water inlet pipe 5, water inlet area 2, water outlet area 1, wetland bed 3, Sewage flows into the bottom end of the water inlet area 2 through the water inlet pipe 5, and flows into the wetland bed 3 from the water inlet area 2 through the water inlet pipe 5; the bottom is also provided with an outlet valve 10 for draining the sewage ;

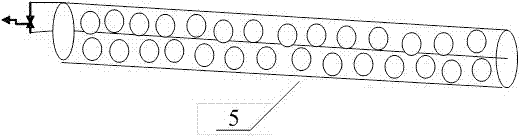

[0032] Step B: If image 3 As shown, the water inlet pipe 5 (one end is open and the other end is closed) is tiled on the surface of the artificial wetland, and there are a plurality of holes distributed on both sides of the bottom of the pipe;

[0033] Step C: the artificial wetland bed 3 is a reinforced concrete or other waterproof material structure, and the gravel 7 with a particle diameter of 3-5cm is paved for 1...

Embodiment 2

[0035] Establish artificial wetlands (length×width×height, 9m*3m*1.0m) in low-lying areas, lay pipelines as described in Example 1, and fill in 10cm of gravel with a particle size of 3-5cm and crushed stones with a particle size of 1-3cm. Stone 10cm, biological oyster shell 30cm, PVC soft board with mesh (particle size 5cm) and planting soil 50cm (5:4:1 sea sand:silt:stone rice with particle size 5mm), the distance between plants is 1m, and the distance between rows is 1m The specifications are planted into the Sonneratia seedlings. Three months after the plants were planted, hand-stocking of dentate crabs and pleated crabs (stocking density of 3-5 / m 2 ), stocking mudskippers (the stocking density is 1-2 / m 2 ); stocking clamworms (stocking density of 2-5 / m 2 ). At a hydraulic load of 5 m 3 d -1 , under the operating parameters with a residence time of about 3 days, after nearly three years of operation, the dissolved oxygen in the influent water is very low, mostly less ...

Embodiment 3

[0037] Establish artificial wetlands in low-lying places (length×width×height, 9m*3m*1.2m), lay pipes as mentioned above, fill in 10cm of gravel with a particle size of 3-5cm, and 10cm of gravel with a particle size of 1-3cm , biological oyster shell 40cm, PVC soft board with mesh (particle size 2mm) and planting soil 60cm (6:2:2 sea sand:silt:stone rice with particle size 5mm), the distance between plants is 0.3m, and the distance between rows is 0.3 The size of m is planted into the candela seedlings. Three months after the plants were planted, hand-stocking of the Sesoria dentatus and the Sesame pleats (stocking density of 3-5 / m 2 ), stocking pseudo-black snails and black-ringed left-shaped snails (stocking density is 1-3 / m 2 ), stocking glandular spiny clamworms (stocking density of 2-5 / m 2 ). At a hydraulic load of 5 m 3 d -1 , under the operating parameters with a residence time of about 3 days, after nearly three years of operation, the dissolved oxygen in the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com