Film coating correction plate and assembly method thereof

An assembly method and a technology for correcting plates, which are applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of difficulty in guaranteeing the quality of the coating film, poor versatility, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

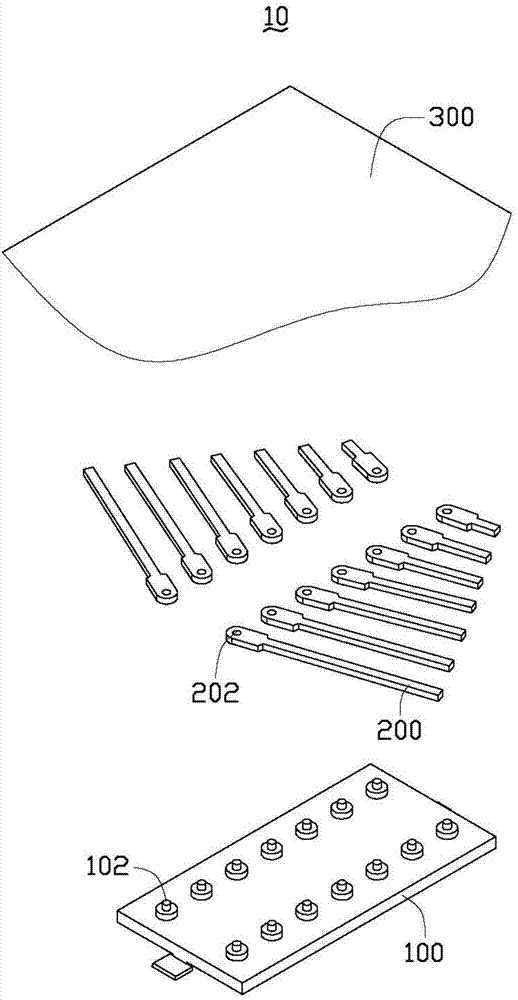

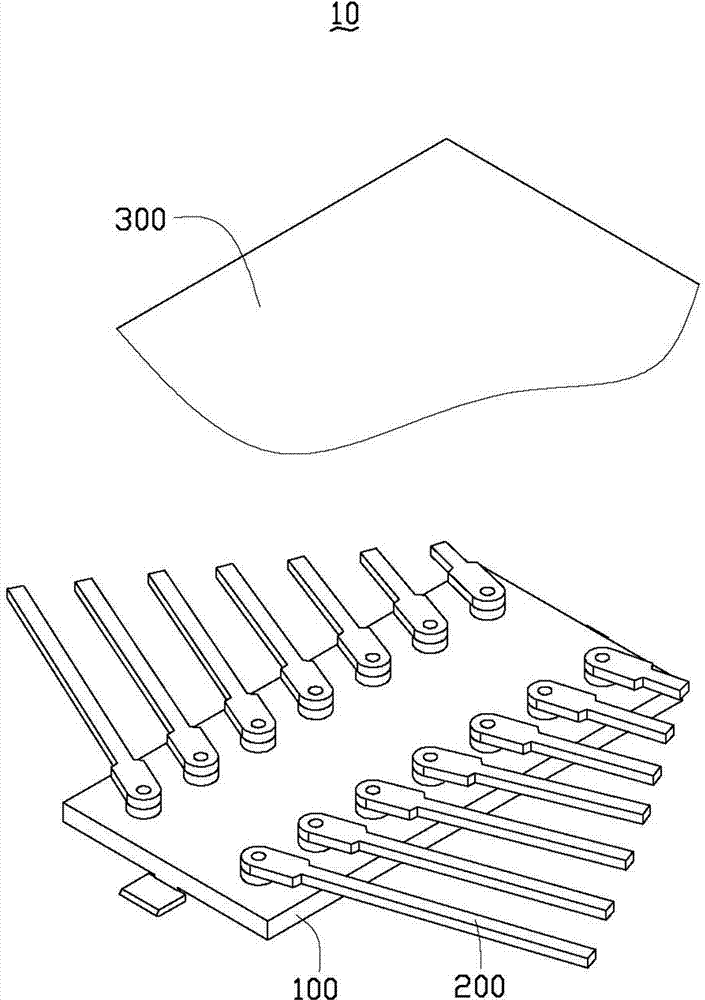

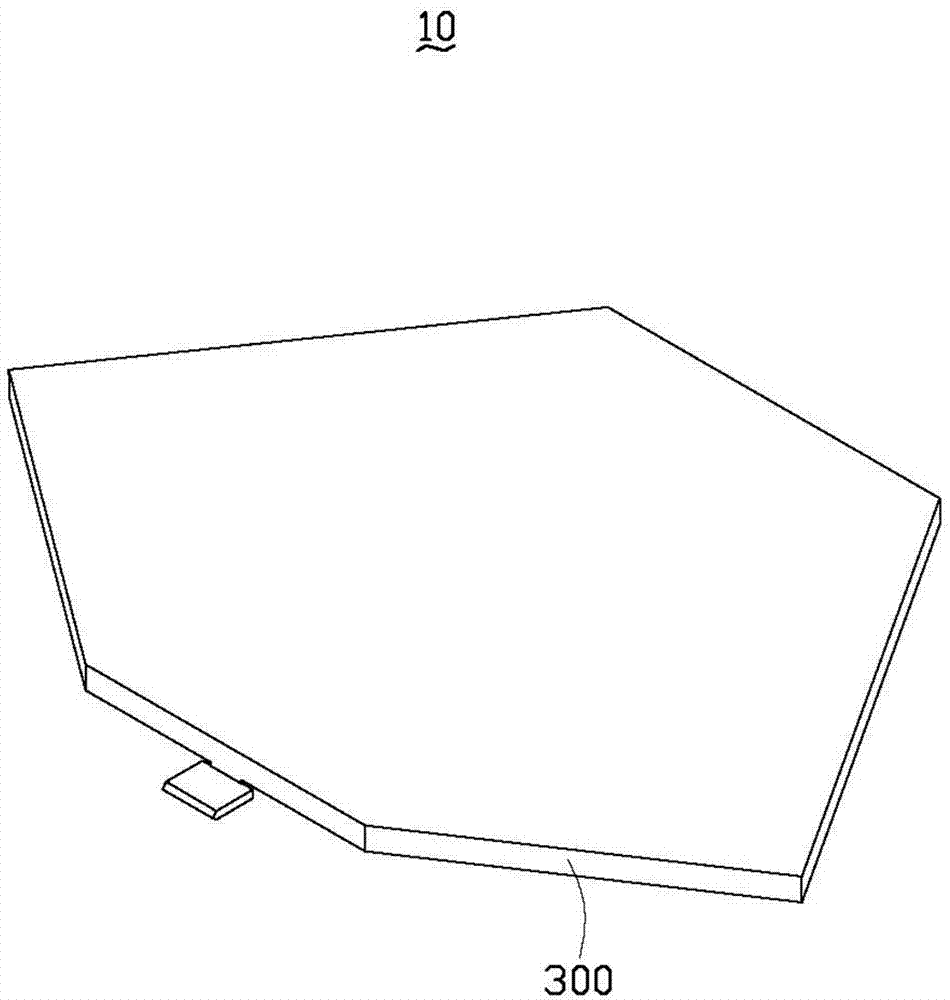

[0021] see Figure 1-4 , the coating correction plate 10 according to the preferred embodiment of the present invention includes a substrate 100 , at least one wing 200 with different lengths and an aluminum foil 300 . The at least one wing 200 is detachably and rotatably assembled to the substrate 100 . The aluminum foil paper 300 wraps the substrate 100 and the flap 200 assembled on the substrate 100 along the outer contour 400 of the substrate 100 and the flap 200 assembled on the substrate 100 .

[0022] Specifically, the coating correction plate 10 can be obtained through the assembly method of the coating correction plate in the preferred embodiment of the present invention, which includes:

[0023] providing the substrate 100, a plurality of wings 200 with different lengths and the aluminum foil 300;

[0024] Select at least one fin 200 from the plurality of fins 200 according to the coating requirements;

[0025] Select an assembly position from the substrate for ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com