Light bastose and flame-retardant polypropylene fiber composite board and method for manufacturing same

A technology of flame-retardant polypropylene and composite boards, which is applied in the fields of plant fiber, fiber treatment, textiles and papermaking, etc. It can solve the problems of complex production process, insufficient flame-retardant effect, and uneven dispersion of product raw materials, so as to improve production efficiency and facilitate molding , the effect of excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

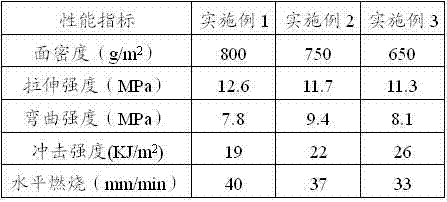

Examples

Embodiment 1

[0032] Weigh raw materials (kg) according to the following weight:

[0033] Jute fiber (flame retardant treatment) 25 kg, 25% by mass,

[0034] 75 kg of flame-retardant polypropylene fiber, 75% by mass,

[0035] Among them, 50kg of RF-203Ⅲ liquid environmental protection flame retardant (solid content is 25%) is used in the flame retardant treatment of hemp fiber.

[0036] The method for producing this hemp fiber / flame-retardant polypropylene fiber lightweight composite board:

[0037] Soak the unpacked chopped jute fiber (white, length 80mm) at 20°C in 50kg of flame retardant impregnation solution with a solid content of 25% for 30 minutes, and then roll it off; Dry until the moisture content of the hemp fiber is less than 5%; mix 25kg of jute fiber after flame-retardant treatment and 75kg of flame-retardant polypropylene fiber (white, length 60mm) evenly, perform opening treatment, carding and forming, and cross-lapping in the longitudinal and transverse directions , thro...

Embodiment 2

[0039] Weigh raw materials (kg) according to the following weight:

[0040] Jute fiber (flame retardant treatment) 35 kg, 35% by mass,

[0041] 65 kg of flame-retardant polypropylene fiber, 65% by mass,

[0042]Among them, 50kg of RF-203Ⅲ liquid environmental protection flame retardant (solid content is 25%) is used in the flame retardant treatment of hemp fiber.

[0043] Soak the unpacked chopped jute fiber (white, length 110mm) in 50kg of flame retardant dipping solution with a solid content of 25% at 40°C for 15 minutes, and then pad it clean; Dry until the moisture content of the hemp fiber is lower than 5%; mix 35kg of jute fiber after flame-retardant treatment and 65kg of flame-retardant polypropylene fiber (white, length 90mm) evenly, perform opening treatment, carding and forming, and cross-lapping in the longitudinal and transverse directions , through the upper and lower needling machines to form a felt to obtain hemp fiber / flame-retardant polypropylene fiber compo...

Embodiment 3

[0045] Weigh raw materials (kg) according to the following weight:

[0046] Jute fiber (flame retardant treatment) 45 kg, 45% by mass,

[0047] 55 kg of flame-retardant polypropylene fiber, 55% by mass,

[0048] Among them, 50kg of RF-203Ⅲ liquid environmental protection flame retardant (solid content 25%) is used for the flame retardant treatment of hemp fiber.

[0049] Soak the unpacked chopped jute fiber (white, length 100mm) at 30°C in 50kg of flame retardant impregnation solution with a solid content of 25% for 25 minutes, and then pad it clean; Dry until the moisture content of the hemp fiber is lower than 5%; mix 45kg of jute fiber after flame-retardant treatment and 55kg of flame-retardant polypropylene fiber (white, length 80mm) evenly, perform opening treatment, carding and forming, and cross-lap the web vertically and horizontally , through the upper and lower needling machines to form a felt to obtain hemp fiber / flame retardant polypropylene fiber composite felt;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com