Cast-in-site column with column cap and construction method

A construction method and technology for cast-in-place columns, which are applied in the field of cast-in-place reinforced concrete columns, can solve the problems of difficulty in tying stirrups, difficulty in pouring and tamping, and large safety factor of column sections, so as to reduce construction costs, improve anchoring performance, and improve The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

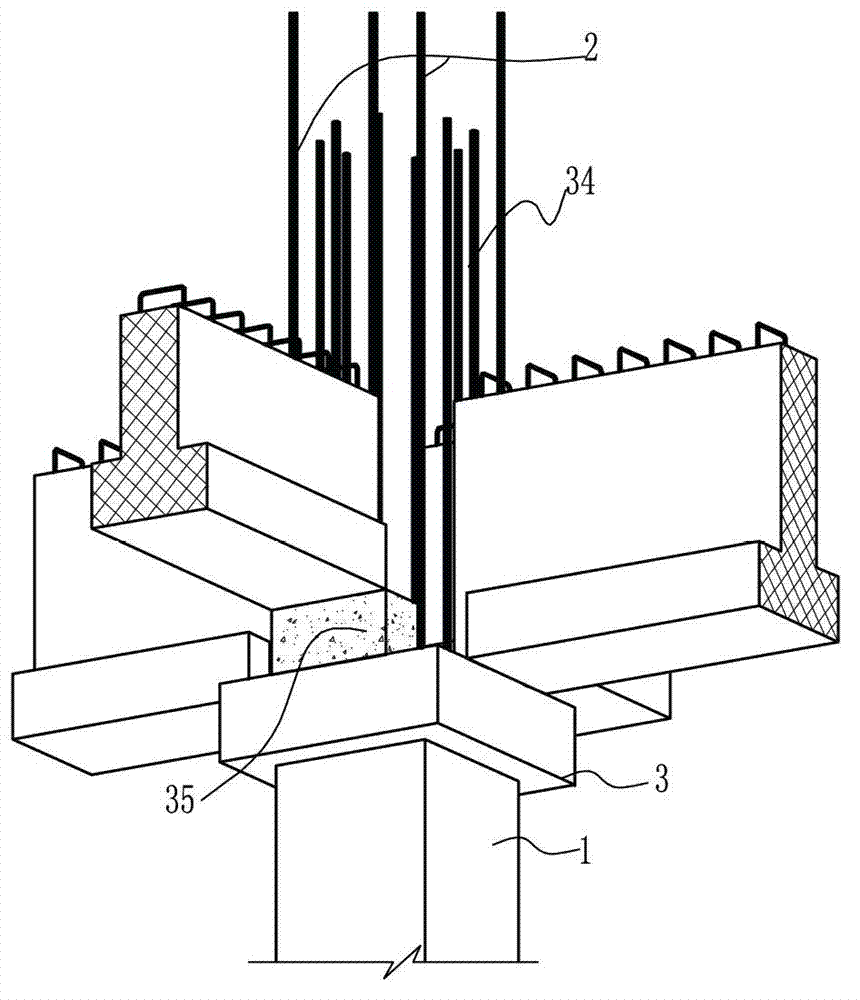

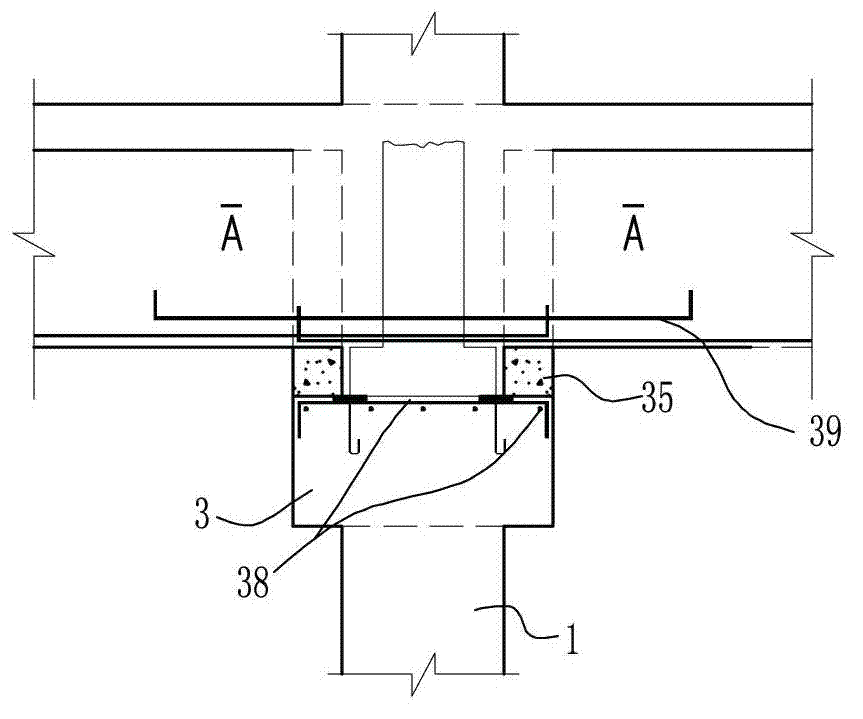

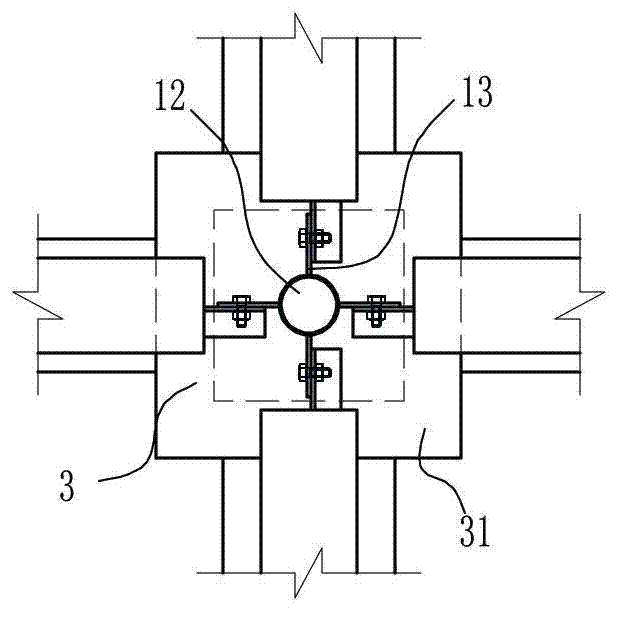

[0040] see Figure 1 to Figure 6 , in an embodiment of a cast-in-place column with a column cap provided by the present invention, it includes a concrete column body 1 and a steel bar 2 embedded in the column body 1, and the column body 1 is connected with the end of the external prefabricated superimposed beam body. A column cap 3 is provided at the joint, and the cross-sectional width of the column cap 3 is greater than that of the column body 1 , and the enlarged cross-sectional portion of the column cap 3 supports the end of the prefabricated beam. In the present invention, a column cap 3 is arranged on the top of the column body 1, and the column cap 3 is convenient for the prefabricated beam to rest thereon, which is convenient for construction, and simultaneously solves the problem of shear weakening of the end section of the prefabricated beam. After the column and precast beam are poured together, the shear capacity of the joint is greatly improved and the seismic per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com