Wall panel for prefabricated building and construction method thereof

一种建筑物、组装式的技术,应用在建筑物构造、建筑、建筑构件等方向,能够解决增加人力费用、施工困难、现场脏乱等问题,达到组装和施工简便、易于加工和运输、节约施工费用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

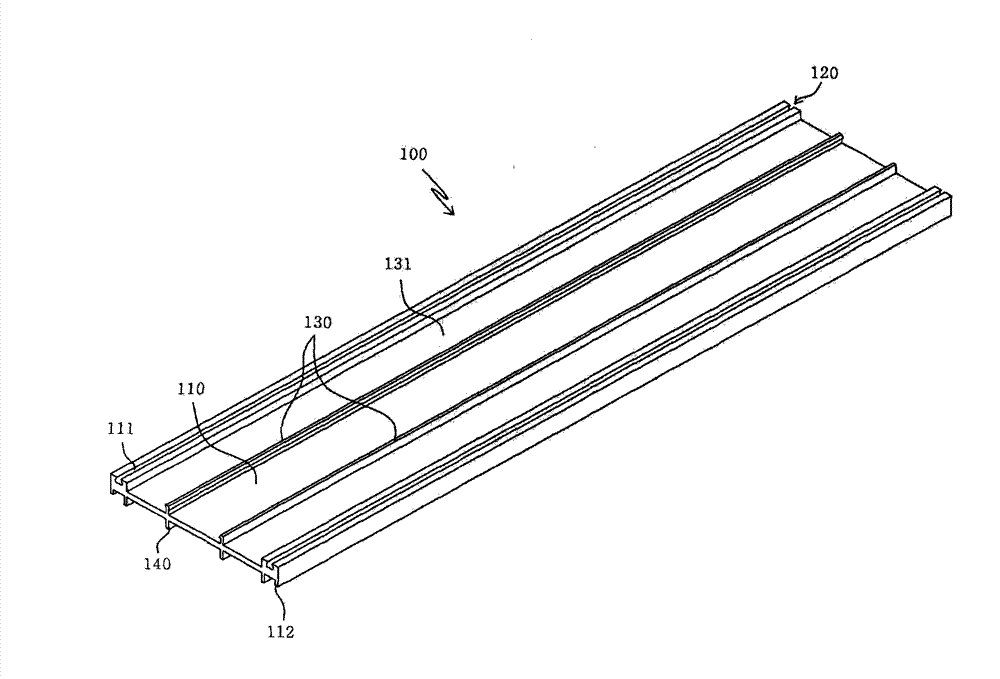

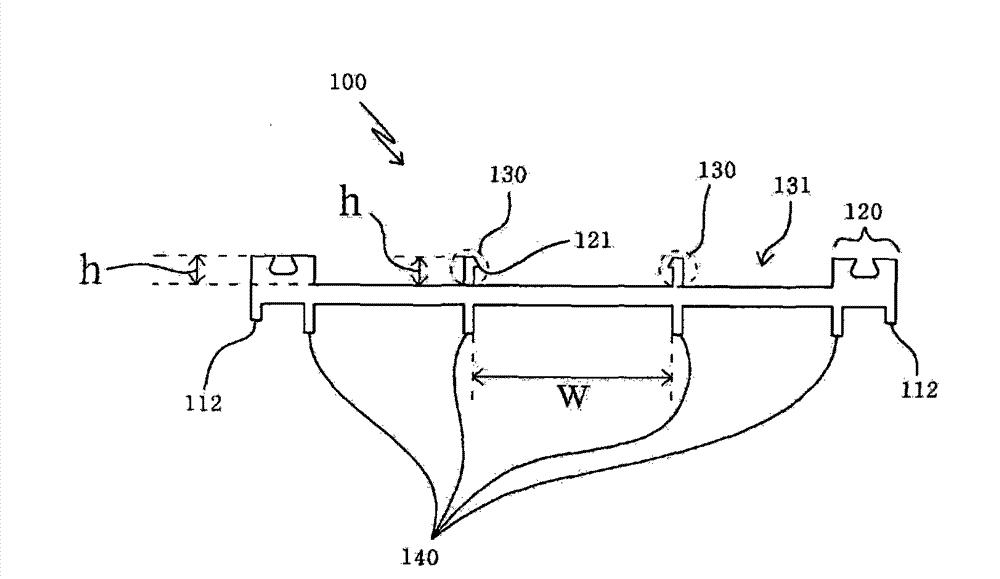

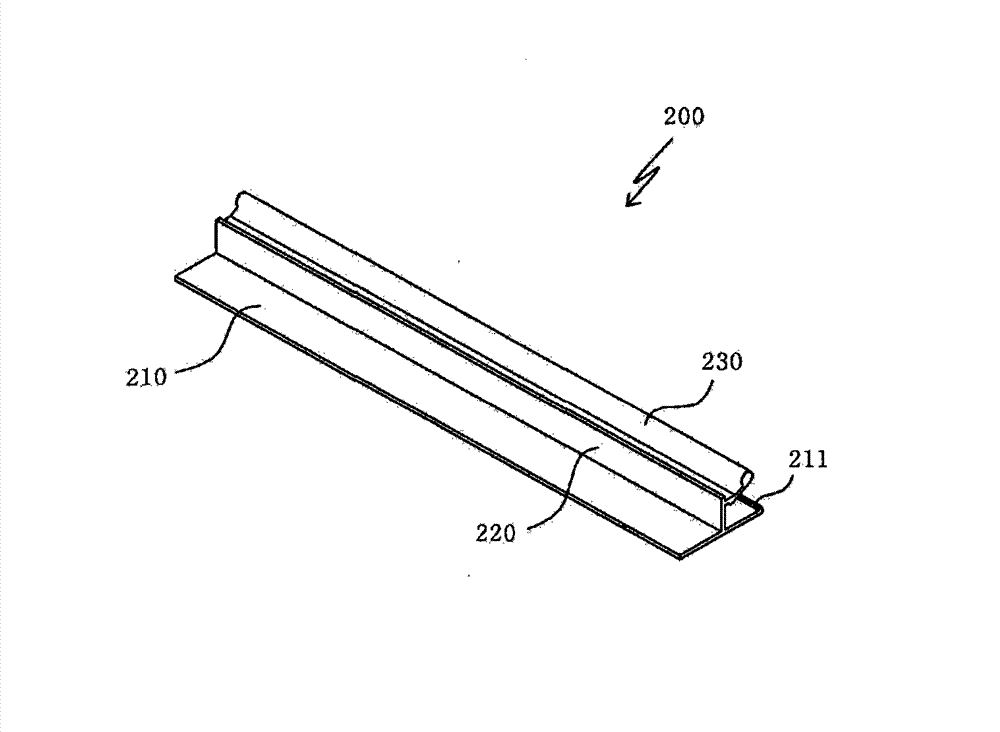

[0067] In order to achieve the above object, the present invention consists of the following parts: a plate fixing frame, which is formed with side support shoulders respectively equipped with grooves above the left and right side ends of the flat plate-shaped support plate, and inside the side support shoulders A pair of support parts are formed, the height of the pair of support parts is the same as the height of the side support shoulders on the support plate, the pair of support parts are formed in a line along the length direction in a manner of facing each other and having the same width, and the one pair of support parts The inner side of the supporting part is provided with anti-off shoulders, shoulders are respectively formed under the left and right ends of the support plate, and a plurality of leg parts are formed at the same height on the inner side of the shoulders. The groove portion formed between the side support shoulder and the support portion is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com