Fuel supply system

A technology for a fuel supply system and a fuel supply device, which is applied in the directions of fuel injection control, combustion engine, internal combustion piston engine, etc., can solve the problems of difficulty in reducing current consumption, large valve lift, and inability to remove foreign matter, and achieves a reduction in the passage of electricity. Effectiveness of flow rate, failure avoidance, and current consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

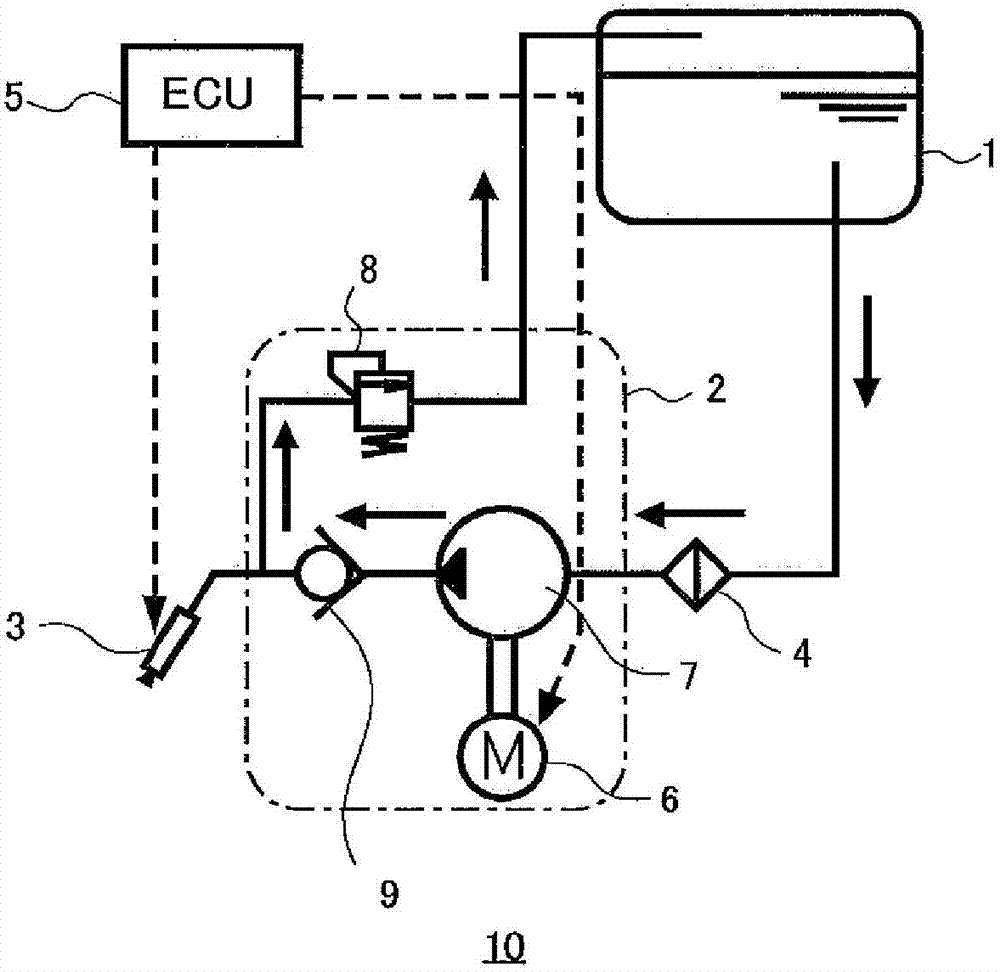

[0043] The fuel supply system according to Embodiment 1 of the present invention will be described. figure 1 It is a block diagram of the fuel supply system of Embodiment 1.

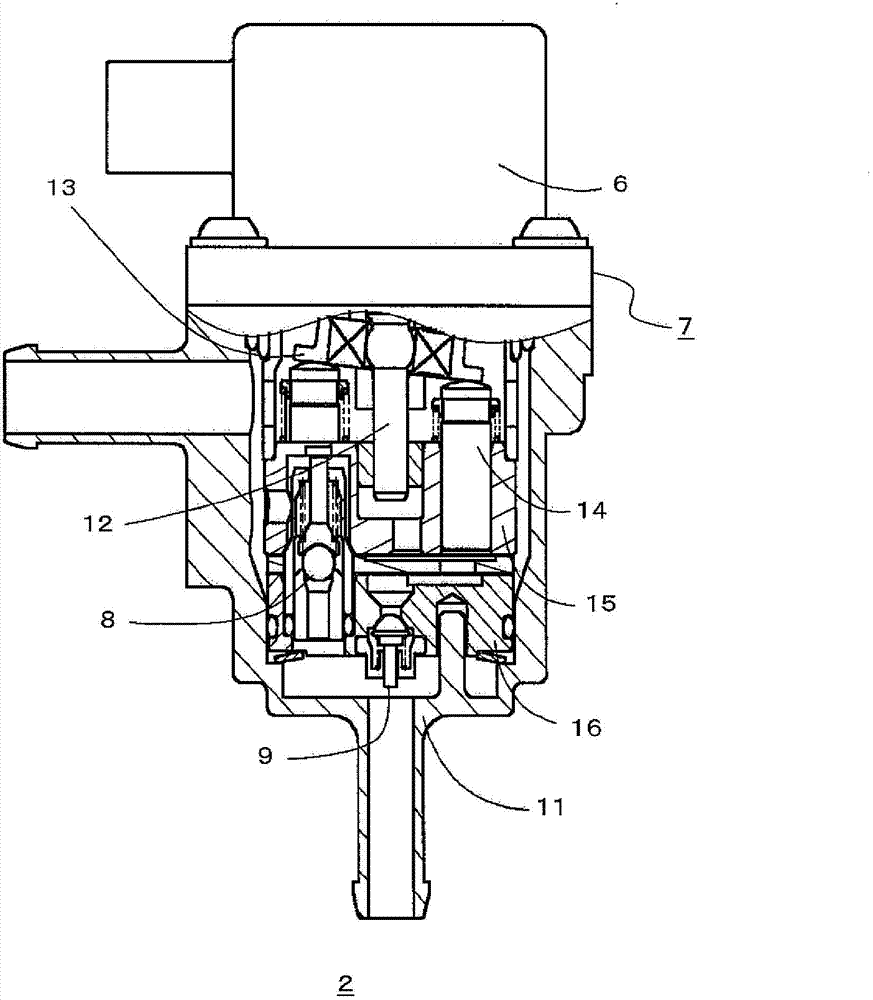

[0044] exist figure 1 Among them, the fuel supply system 10 includes: a fuel tank 1 for storing fuel; a fuel supply device 2; a fuel injection device 3 for discharging fuel to an air intake pipe (not shown); and a control unit (hereinafter referred to as ECU) 5 that controls the fuel supply device 2 and the fuel injection device 3 . The fuel supply device 2 includes: a brushless motor 6 ; a piston pump 7 as a pump device driven by the brushless motor 6 as described below; a pressure regulating device 8 ; and a fuel pressure maintaining valve 9 . In addition, the fuel piping between the fuel tank 1 and the fuel injection device 3 is configured such that fuel flows in a certain direction without backflow. In addition, in figure 1 In the illustrated case, the pressure regulating device 8 is built in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com