A low-noise centrifugal pump

A centrifugal pump, low-noise technology, applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of difficult film installation and fixation, unsuitable for engineering applications, unstable film, etc., to achieve stable and reliable structure, reduce broadband Effects with flow noise and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

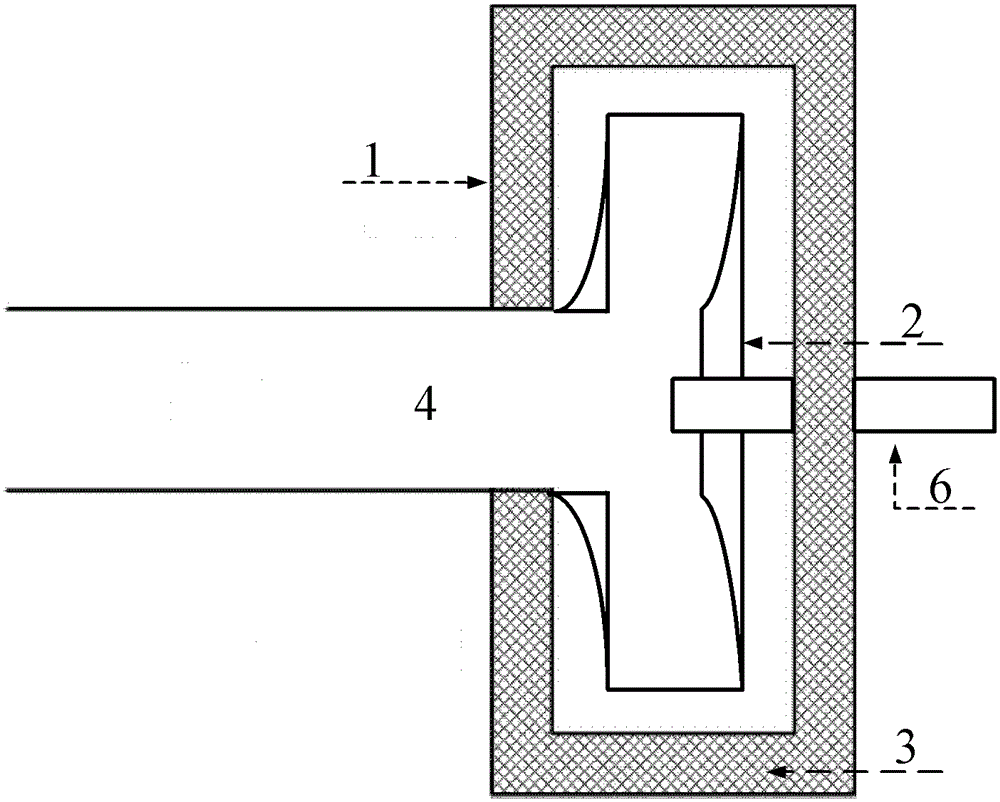

[0022] Such as figure 1 Shown is part of the pump inlet 4 of one embodiment of the present invention. The implementation structure of centrifugal pump flow noise control consists of volute 1, impeller 2, rubber layer 3 and shaft 6. The increased width and radius of the volute 1 is filled with rubber, the position of the inner edge of the rubber is determined by the hydrodynamic characteristics of the design of the centrifugal pump.

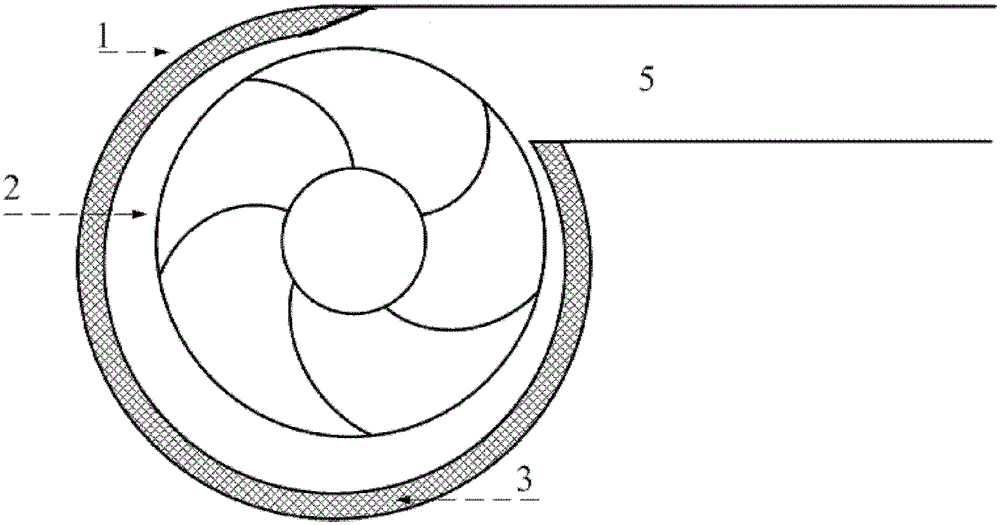

[0023] Such as figure 2 Shown is part of the pump outlet 5 of this embodiment of the invention. and figure 1 Similarly, the increased width and radius of the volute 1 are filled with rubber to partially offset the radiated noise on both sides of the impeller 2 .

[0024] In this embodiment, although rubber or polyurethane is used as the acoustic filling material, the filling material of the present invention is not limited to these two, and other materials that meet the requirements may also be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com