Damper capable of eliminating damping oil foam

A shock absorber and foam technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of abnormal sound, noise and vibration of the shock absorber, and achieve the elimination of lost motion and distortion, The effect of eliminating abnormal noise and improving comfort and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

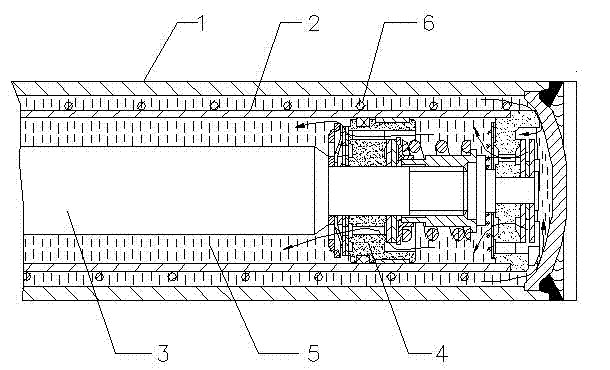

[0011] Such as figure 1 Shown is a shock absorber that can eliminate the shock absorbing oil foam, including the oil storage tank 1, the working cylinder 2 in the oil storage tank 1, the piston rod 3 in the working cylinder 2 and the piston rod 3 connected Piston 4 5, a defoaming spring 6 is fixedly sleeved on the outer wall of the working cylinder 2 .

[0012] When the shock absorber piston 4 moves up and down, the shock absorber oil 5 circulates in the oil storage tube 1 and the working cylinder 2 in the direction of the arrow in the figure, and the shock absorber oil 5 is generated in the oil storage tube 1 during the flow process. A large number of damping oil foams, these foams move with the flow of the damping oil, when these foams meet the defoaming spring 6 fixedly set on the outer wall of the working cylinder 2 during the movement, the foams b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com