A Porous Media Regeneration Microscale Burner

A technology of micro-scale combustion and porous media, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems that the internal combustion organization effect is not the best, the overall temperature of the radiation surface is not ideal, etc., to achieve extended residence time The effect of increasing the time and reaction temperature and improving the degree of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

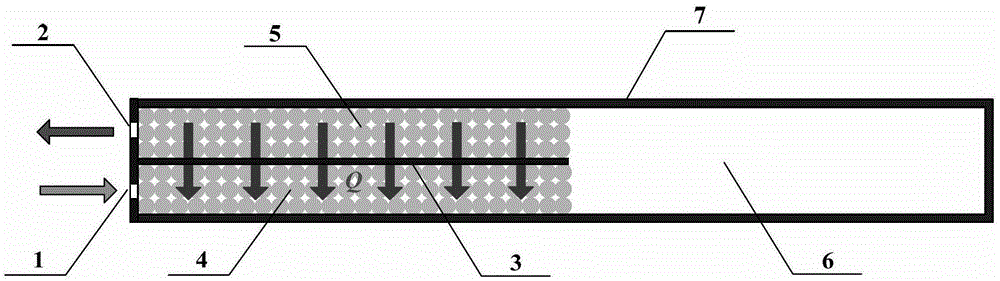

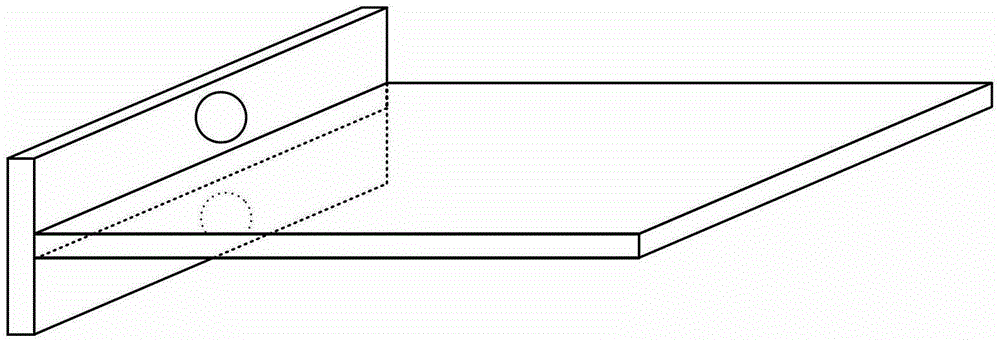

[0015] like figure 1 The shown porous medium regenerative flat plate micro-scale burner includes an air inlet 1, an exhaust port 2, a "T"-shaped partition 3, a lower porous medium area 4, an upper porous medium area 5, a combustion area 6 and Burner outer wall (radiation wall) 7.

[0016] In the present invention, the outside of the micro-scale burner has a rectangular parallelepiped structure, the length and width of the upper and lower outer walls are both 10mm×10mm, and the overall height of the outside is 2.4mm. Considering the actual effect of photoelectric conversion, the combustion The device is processed with SiC ceramic material with an emissivity of 0.9 and strong high temperature resistance; when making it, firstly, a special boring tool can be used to process a SiC block that meets the above-mentioned appearance size into an open on the left and closed on the right. The internal rectangular channel structure has a channel height of 2 mm, that is, the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com