Method for coating stationary phase in capillary column

A technology of capillary column and stationary phase, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that it is difficult to form uniform thickness, and achieve the effect of good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

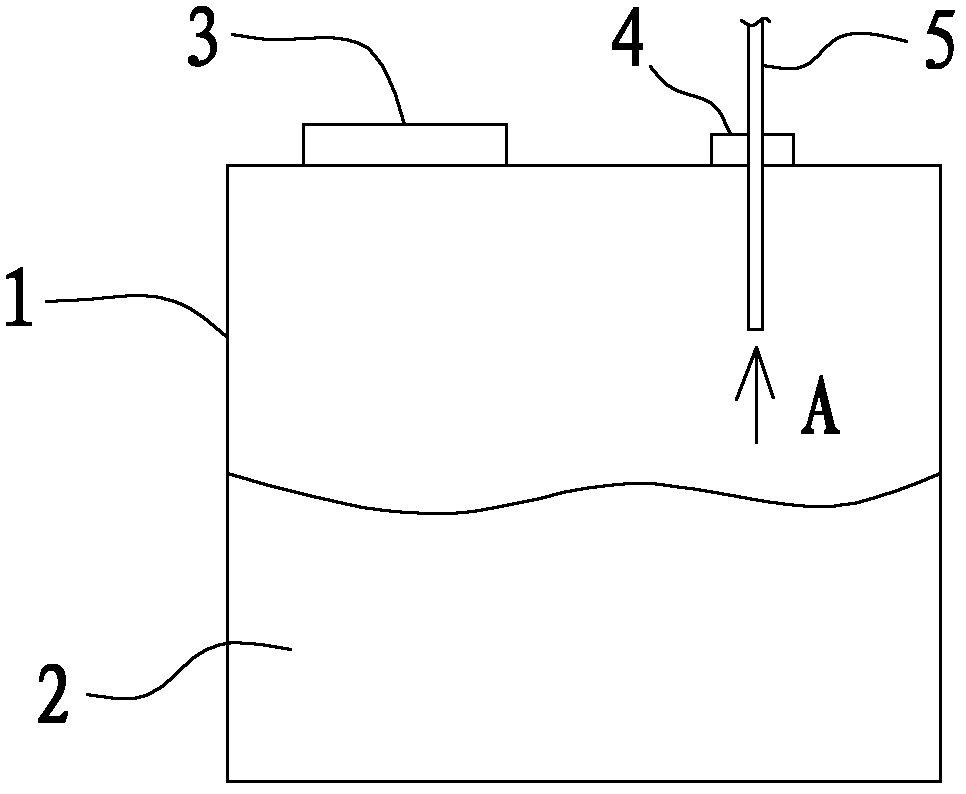

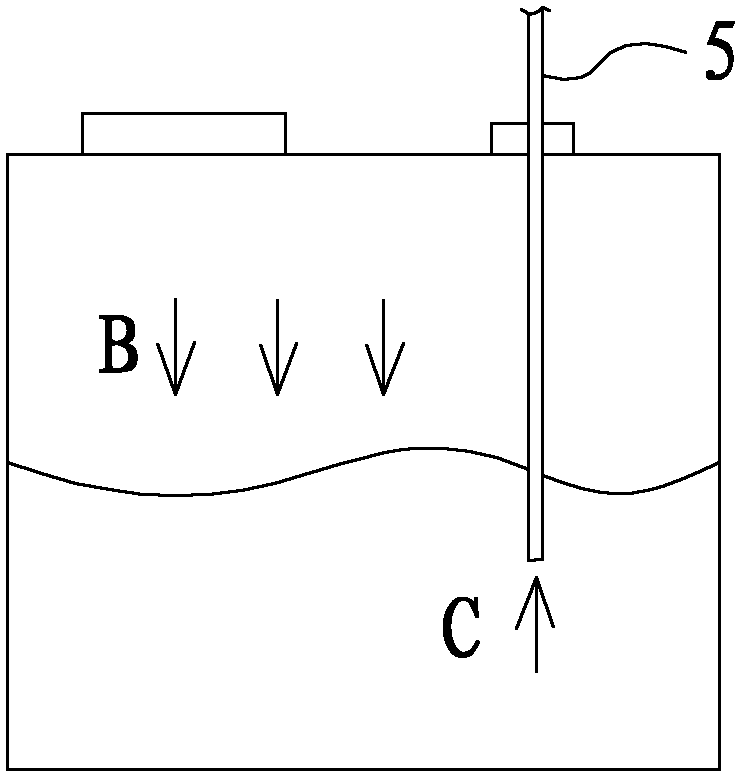

[0016] Referring to accompanying drawing, in order to realize the coating device that coating method of the present invention adopts comprises the airtight container 1 that is used to hold coating liquid 2, this airtight container 1 top is provided with plug-in port, and this plug-in port is filled with elastic sealing plug 4, The elastic sealing plug 4 is provided with a through hole for inserting the capillary column 5 , and the inner wall of the through hole is in interference fit with the outer wall of the capillary column 5 to be processed.

[0017] The top of the airtight container 1 can also be provided with a sealing cover 3, the sealing cover 3 is closed during use, and the coating liquid 2 is convenient to be filled when the sealing cover 3 is opened. Good airtightness is ensured after the capillary column 5 is inserted, and the elastic sealing plug 4 can be made of a material that does not react with the coating liquid, such as tetrafluoroethylene.

[0018] When usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com