Magnetostriction high-precision time measurement system based on electro-magnetic induction

A time measurement and magnetostrictive technology, which is applied in the direction of electrical unknown time interval measurement, devices and instruments for measuring time interval, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment this patent is described further as follows.

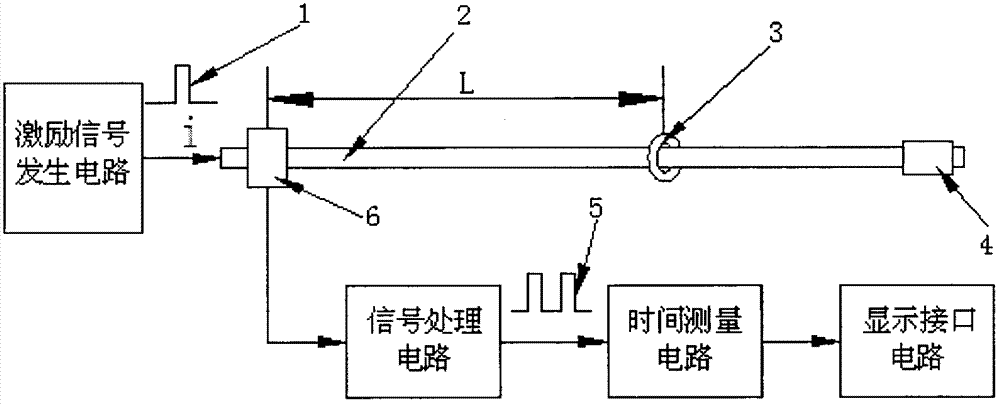

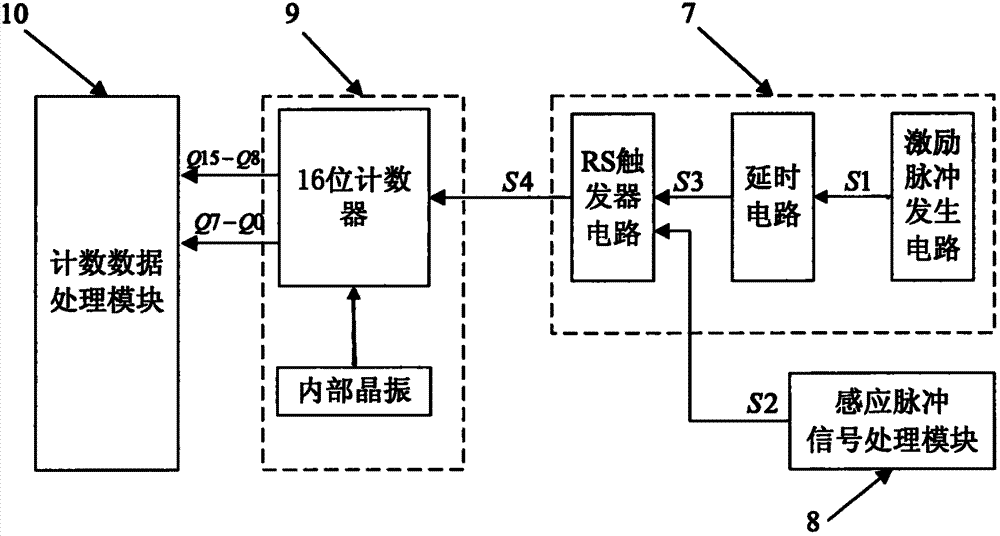

[0019] The invention is a magnetostrictive high-precision time measurement system based on electromagnetic induction applied to a magnetostrictive displacement sensor. The system includes four parts: a time interval acquisition module 7 , an induction pulse signal processing module 8 , a counting module 9 and a counting data processing module 10 .

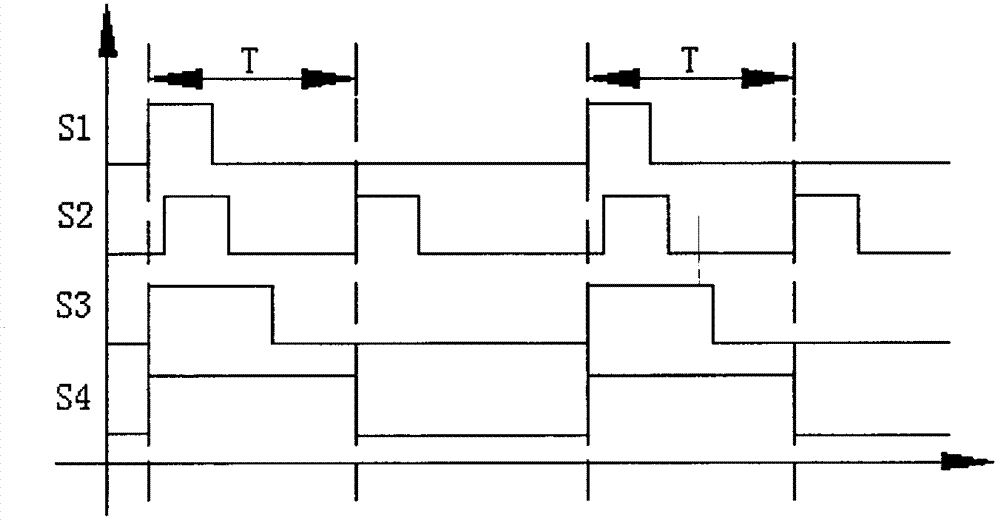

[0020] The circuit connection of each part of the present invention is as image 3 As shown, at first, the excitation pulse S1 is generated by the excitation pulse generation circuit in the time interval acquisition module 7, such as figure 1 As shown, after being amplified, it is applied to the waveguide wire 2 to generate a weak echo signal, which is input to the induction pulse signal processing circuit 8 after being amplified and filtered to eliminate the secondary echo 11 (such as Figure 4 Shown), get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com