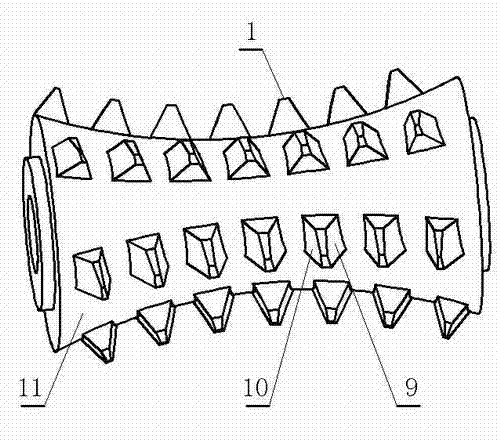

Modeling method of plane secondary envelope torus worm-drive worm gear hob tooth profile

A plane quadratic envelope and worm gear hob technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the difficulty in solving nonlinear equations, and non-unique solutions of nonlinear equations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

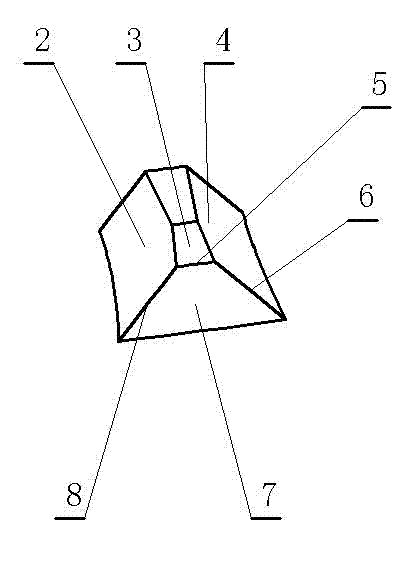

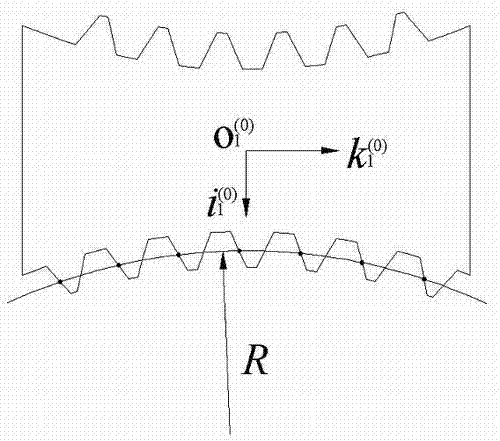

[0045] Each point on the tooth surface of the basic worm of the hob corresponds to a certain and , to find the point coordinates on the two cutting edges of the worm gear hob, that is, to find the corresponding and . and The geometric meaning can refer to Figure 4 , is a coordinate system fixedly connected to the parent plane, is a point on the contact line between the mother plane and the basic worm tooth surface of the hob, point in coordinate system The middle coordinates are , as the axis and angle. when fixed ,Variety , a series of corresponding point these The points form a continuous curve, that is, the parent plane rotates through the angle In the case of the contact line with the basic worm tooth surface of the worm gear hob, such as Figure 5 curve shown . when fixed ,Variety , what is obtained is a helical line along the tooth length direction, such as Figure 5 curve shown . Based on this change rule, refer to Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com