Manufacturing method of artificial rock core for simulating borehole drilling

A technology of artificial cores and production methods, applied in the preparation, sampling, and instrumentation of samples for testing, to achieve the effects of simple production methods, economical and easy-to-obtain raw materials, and avoid difficult acquisitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

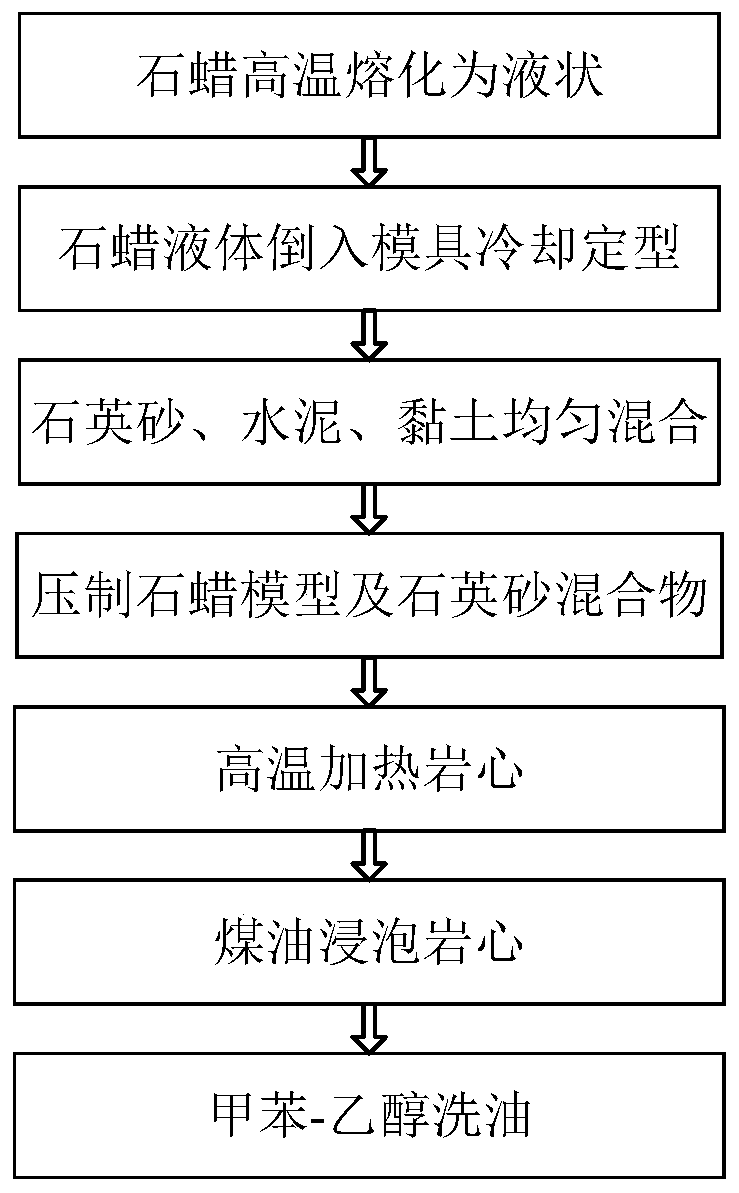

[0077] Present embodiment 1 provides a kind of artificial core making method of simulating borehole drilling, comprises the following steps:

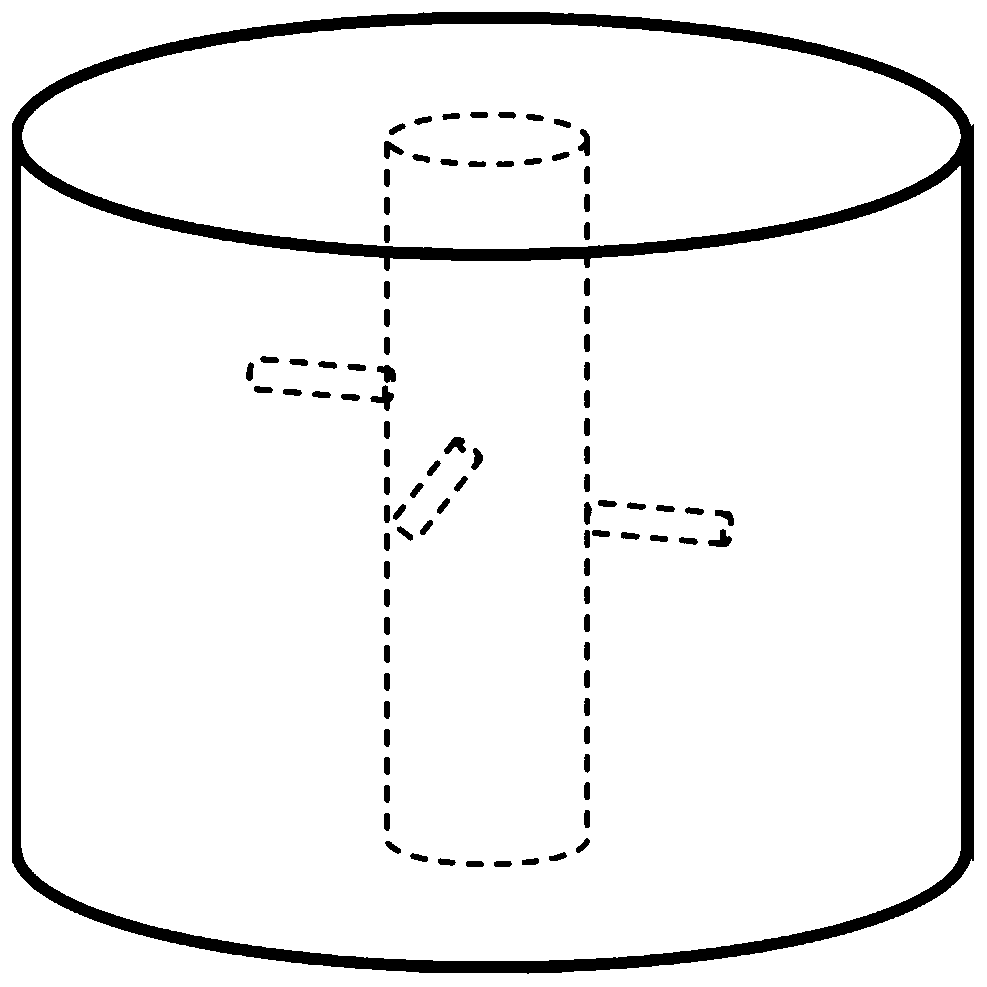

[0078] 1) Use a dryer to heat the Fischer-Tropsch wax to 110°C and melt it into a liquid state, put the melted Fischer-Tropsch wax in the wellbore drilling mold, cool naturally for 24 hours to form, remove the wellbore drilling mold, and obtain the wellbore drilling mold Hole paraffin embryo body; the borehole paraffin embryo body includes a cylindrical body and three staggered cylindrical arms extending integrally from the side wall of the cylindrical body; wherein, the diameter of the cylindrical body is 8mm, The diameter of described cylindrical support arm is 3mm, and the length of described cylindrical support arm is 17mm;

[0079] 2) Mix and stir 500g of 40-mesh quartz sand, 500g of composite Portland cement and 12.5g of clay to obtain mixture A; mix and stir mixture A and water to obtain a mixed slurry; wherein, the mass ratio of...

Embodiment 2

[0087] Present embodiment 2 provides a kind of artificial core making method of simulating borehole drilling, comprises the steps:

[0088] 1) Use a dryer to heat the Fischer-Tropsch wax to 110°C and melt it into a liquid state, put the melted Fischer-Tropsch wax in the wellbore drilling mold, cool naturally for 24 hours to form, remove the wellbore drilling mold, and obtain the wellbore drilling mold Hole paraffin body; the borehole paraffin body includes a cylindrical body and three staggered cylindrical arms extending integrally from the side wall of the cylindrical body; wherein, the diameter of the cylindrical body is 10 mm, The diameter of described cylindrical support arm is 3mm, and the length of described cylindrical support arm is 20mm;

[0089] 2) Mix 400g of 60 mesh quartz sand, 800g of composite portland cement and 10g of clay to obtain mixture A; mix and stir mixture A and water to obtain a mixed slurry; wherein, the mass ratio of quartz sand, cement, clay and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com