Fusion driving subcritical cladding of transmutation subordinate actinium series nuclide

A subcritical and minor actinide technology, applied in the field of minor actinide nuclide transmutation, can solve the problems of high corrosion of molten salt fuel and difficulty in fuel purification and purification, and achieve the effect of compact structure and high filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The structure of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

[0031] Fusion parameters and design requirements adopted in the present invention:

[0032] (1) The large and small radii of the plasma cavity are 3m and 0.75m respectively, the ring diameter ratio is 4, and the elongation ratio is 1.7;

[0033] (2) Fusion power less than 200MW, first wall load less than 1MW / m 2 , the tritium multiplication ratio is greater than 1.15, the energy amplification factor is greater than 10, and the output thermal power is 1500MW;

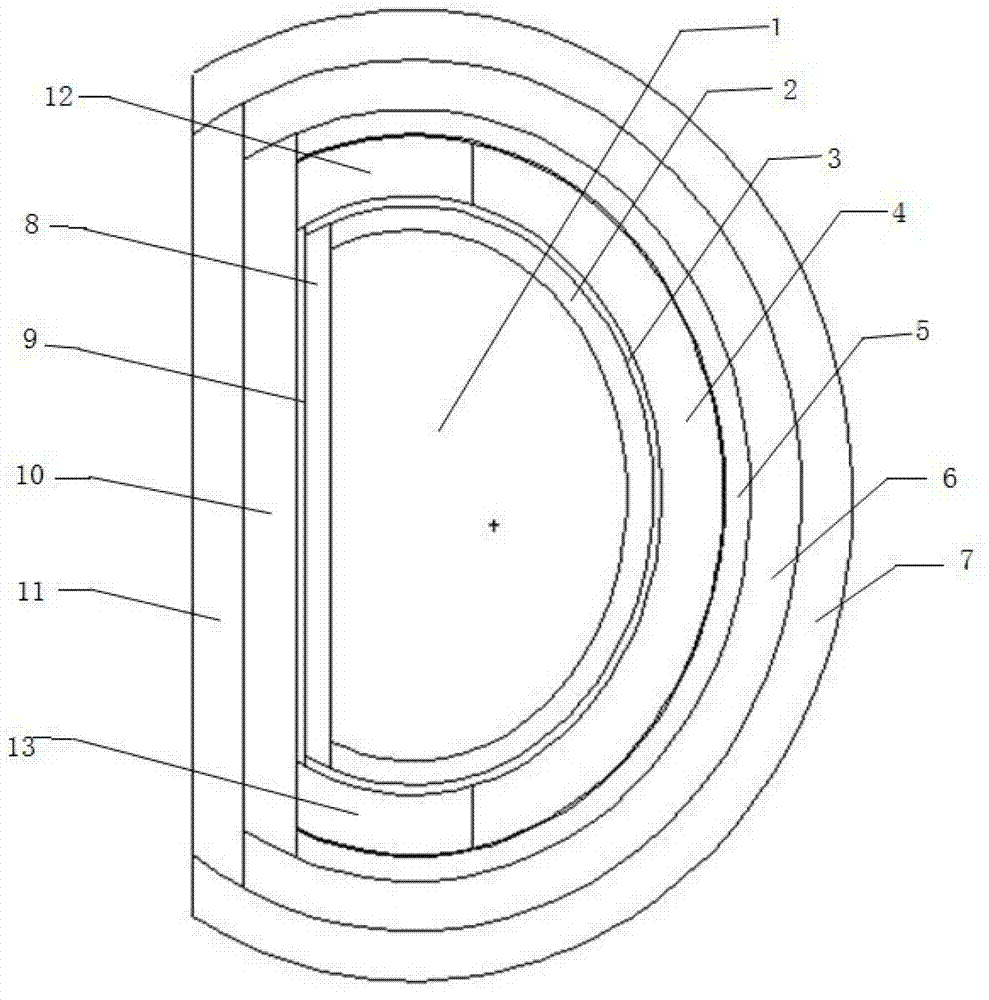

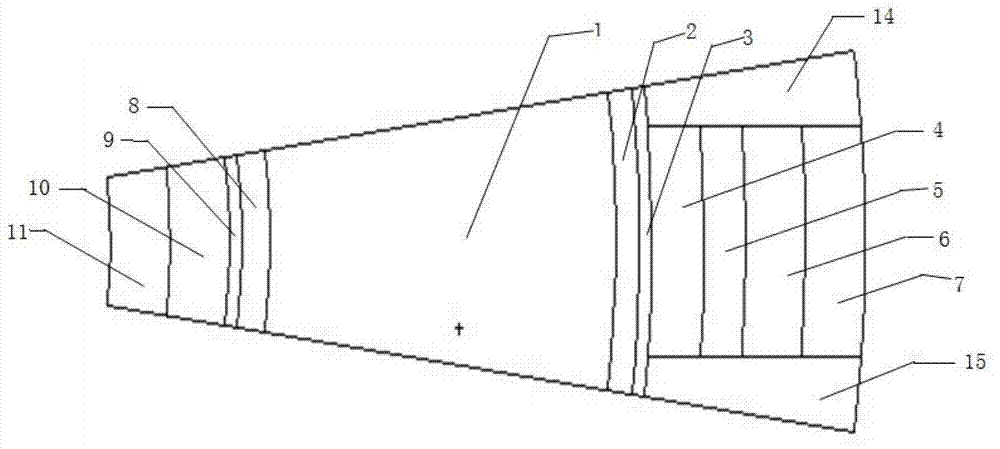

[0034] Such as figure 1 and figure 2 As shown, it is a cross-sectional view of a single module. The overall shape of each cladding module is a "D" shape, including an inner cladding, an outer cladding, and a "D"-shaped plasma chamber 1 formed between the inner cladding and the outer cladding. The inner cladding layer is cylindrical, and radially from the inside to the outside a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com